Do you have a question about the Gardner Denver CHAMPION ROTORCHAMP EFB99B and is the answer not in the manual?

| Brand | Gardner Denver |

|---|---|

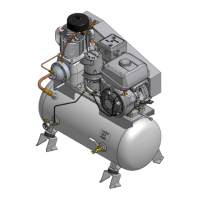

| Model | CHAMPION ROTORCHAMP EFB99B |

| Category | Air Compressor |

| Language | English |

Proper lifting, handling, location, and environmental considerations for installation.

Mounting on a solid surface, enclosure details, and oil reservoir drain.

Requirements for inlet/discharge lines, electrical connections, and grounding.

Essential checks before initial operation, including oil, filters, and electrical.

System pressure, operating mode, and enclosure checks for safe operation.

Procedures for safely starting and stopping the compressor.

General operation, selector switch functions, and protection features.

Details on inlet valve, solenoid valve, and minimum pressure/check valve.

Hourmeter, control box, controller indicators, and their meanings.

Setting load/unload pressure, auto time, and restart options.

Function of oil system, lubrication, cooling, and separation.

Recommended lubricants, specifications, and oil change intervals.

Procedures for checking oil level, adding oil, and maintaining filters/separators.

Checking oil temps, pressures, and maintenance of specific components like the mixing valve.

Procedures for replacing belts, sheaves, shaft seals, and ensuring proper alignment.

How to check and adjust belt tension using force and deflection.

Regular checks and maintenance actions based on operating hours or calendar time.

Summary table of maintenance actions and their recommended intervals.

Lists symptoms like failure to start, stopping early, and pressure issues with causes and remedies.

Addresses high discharge temperature, excessive oil consumption, and oil carryover.

Explains controller indicators and troubleshooting for power, mode, and temperature warnings.

Troubleshooting high/low voltage, fault indicators, and control circuit problems.