Description

4 Dimple Grinder User’s Guide

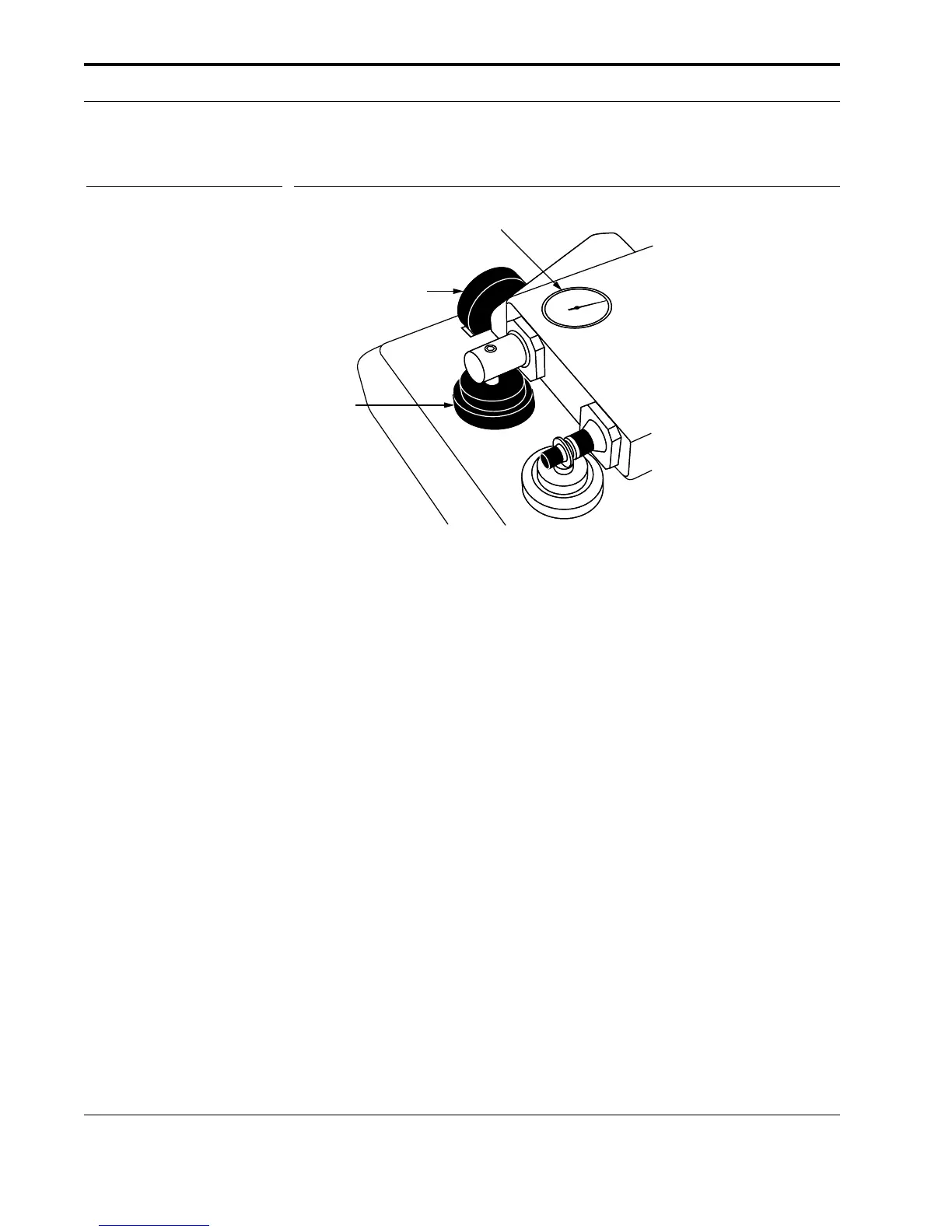

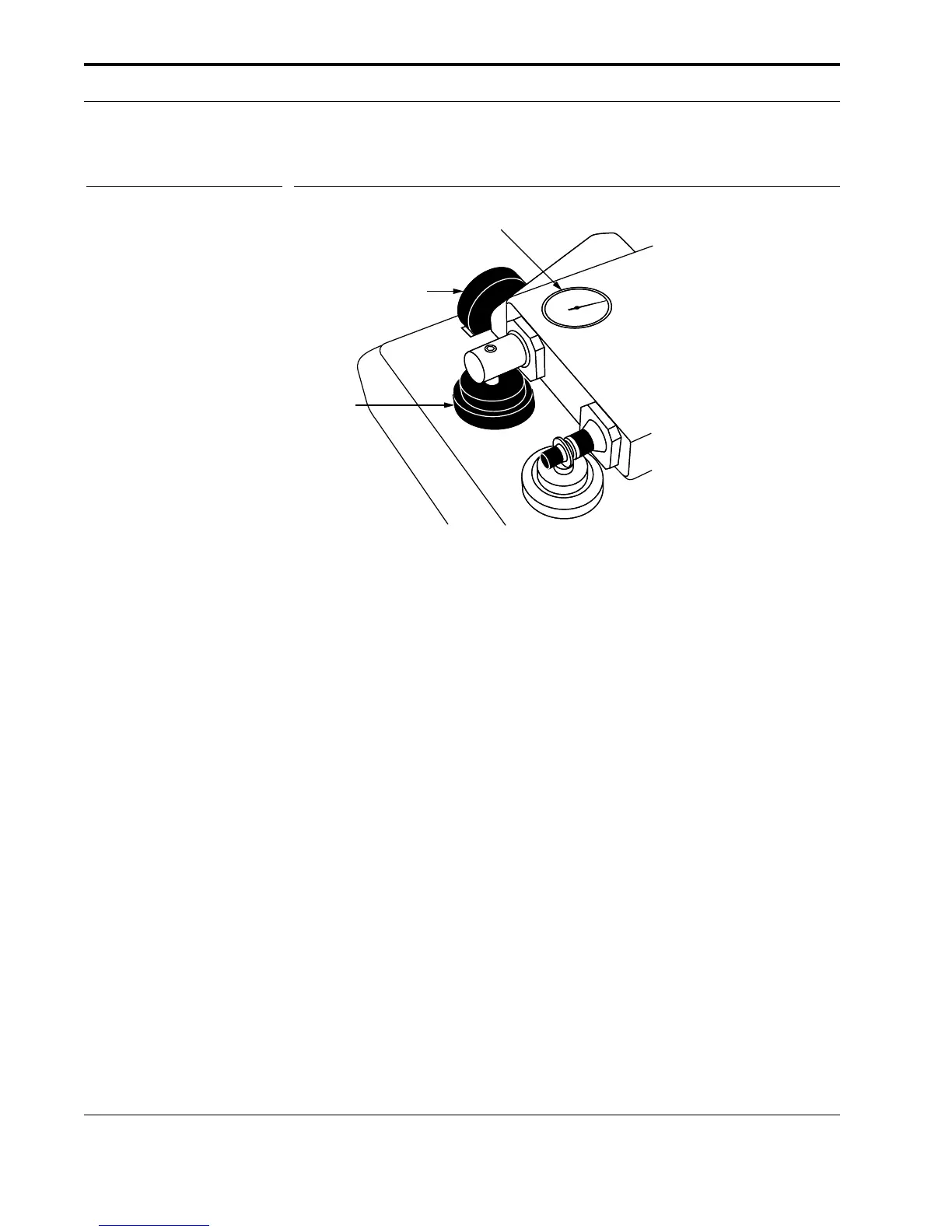

Figure 2 Measuring devices.

The Dial Indicator provides indication of contact between grinding wheel and

specimen and presents an analog display of dimpling progress.

The Micrometer Drive provides a digital readout for setting desired dimple

depth or final specimen thickness.

The end face of the Micrometer sits directly below the stylus of the Dial Indica-

tor (see Figure 8). When the Micrometer end face is raised (by rotating the

Micrometer Drive), it pushes up and raises the stylus by a height change, which

is indicated by the dial/digital display. The stylus and the grinding wheel axle

are both mounted to the Platform. The raising of the stylus results in a corre-

sponding raising of the grinding wheel.

A desired dimple depth (shown in the digital readout) can be set using the

Micrometer (see Section 4.5). As dimpling progresses, the “amount of dim-

pling” can be read on the Dial Indicator.

3.3 Counterweight

Located on the back of the Platform is the Counterweight that supplies the vari-

able load (from 0–40 g) applied to the specimen (see Figure 1). The desired load

can be selected by dialing in the appropriate value on the scale.

Note

: When varying the load, be sure to raise the Platform slightly so the Dial

Indicator stylus is not on the Micrometer end face.

Caution

: Dropping the pivoted Platform may cause considerable damage to the

measuring devices and will void the warranty.

Analog dial

indicator

Raise/lower

cam control

Micrometer

drive

Loading...

Loading...