Open Gate

Figure 8: Re-measure length of Secondary arm

4. Once the dimension is consistent, a new hole can be drilled in the Secondary arm and the arm trimmed to

suit. The gate bracket and Secondary arm should now be fitted.

OUTSWING INSTALLATION

In this type of installation the gate swings outward or away from the operators to the open position (Figure

6). Several factors must be considered to determine the most suitable arm length. These include the drive

through width required, the placement of the operators and the location of the gate. Direct support from the

supplier is always available in these situations.

NOTE: The polarity of the motor connections may need to be reversed on out-swing operation. See the

‘Overloads’ section.

SETTINGS

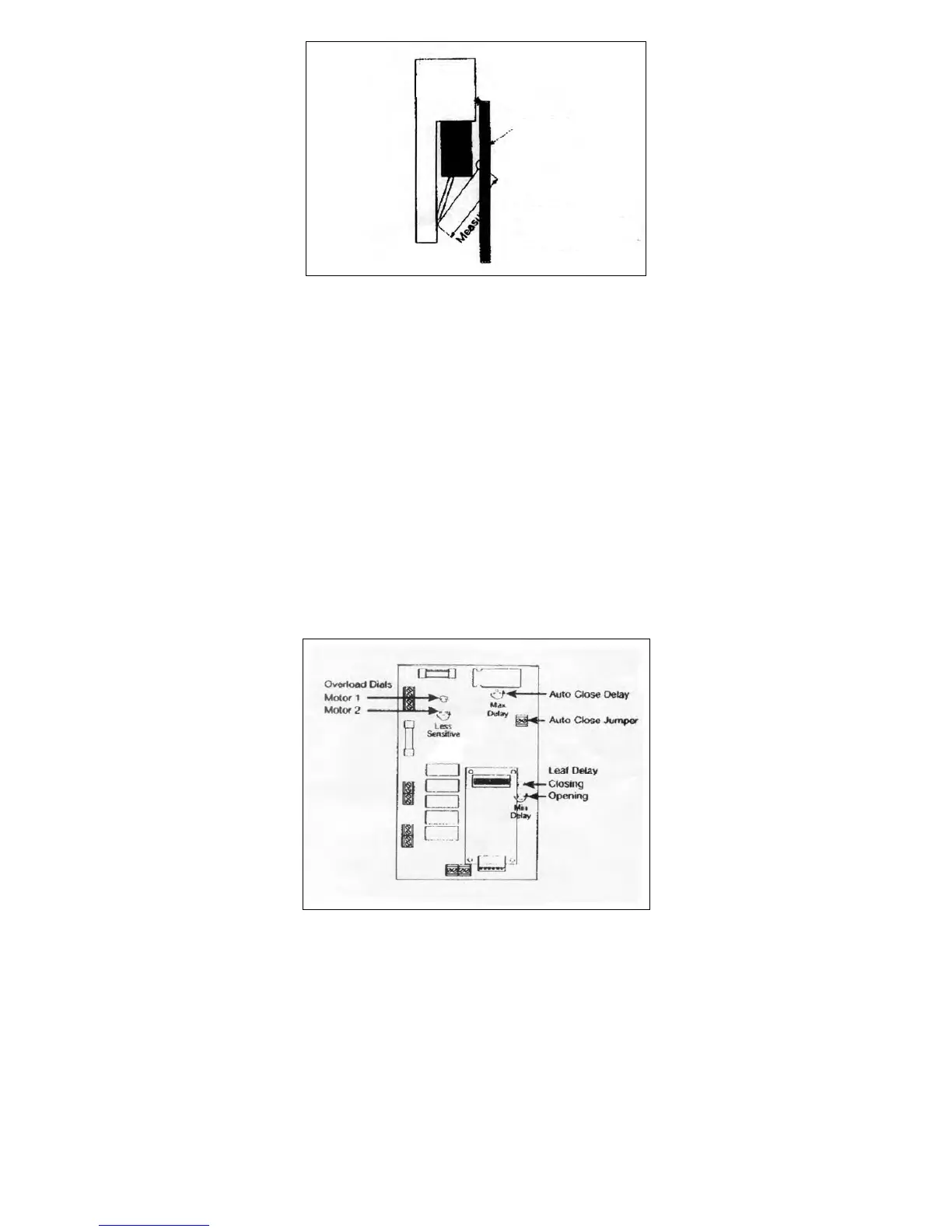

AUTO CLOSE

The gates can be set to automatically close after a specific period.

This feature is activated by fitting a ‘jumper’ across the appropriate connection block (Figure 9) and

adjusting the Auto Close dial to the required time delay. Turning the dial anticlockwise increases the time

until the gates automatically close.

Figure 9: Settings

OVERLOAD

The overloads (Figure 9) are preset to maximum sensitivity i.e. slight pressure on the gate during operation

will cause the operator to stop if it is opening or stop and automatically reverse if it is closed.

NOTE: If these functions are reversed i.e. the gate stops when closing and stops and automatically reversed

when opening, then the polarity of the motor connections must be reversed, and the limit switch cams

adjusted.

There is one overload for each gate, as indicated on the circuit board. To reduce the sensitivity, turn the

overload dials in the anticlockwise direction.

Be Careful! Large reductions in sensitivity may allow the gates to exert excessive pressure on people or

vehicles trapped in the path of the gates.

Loading...

Loading...