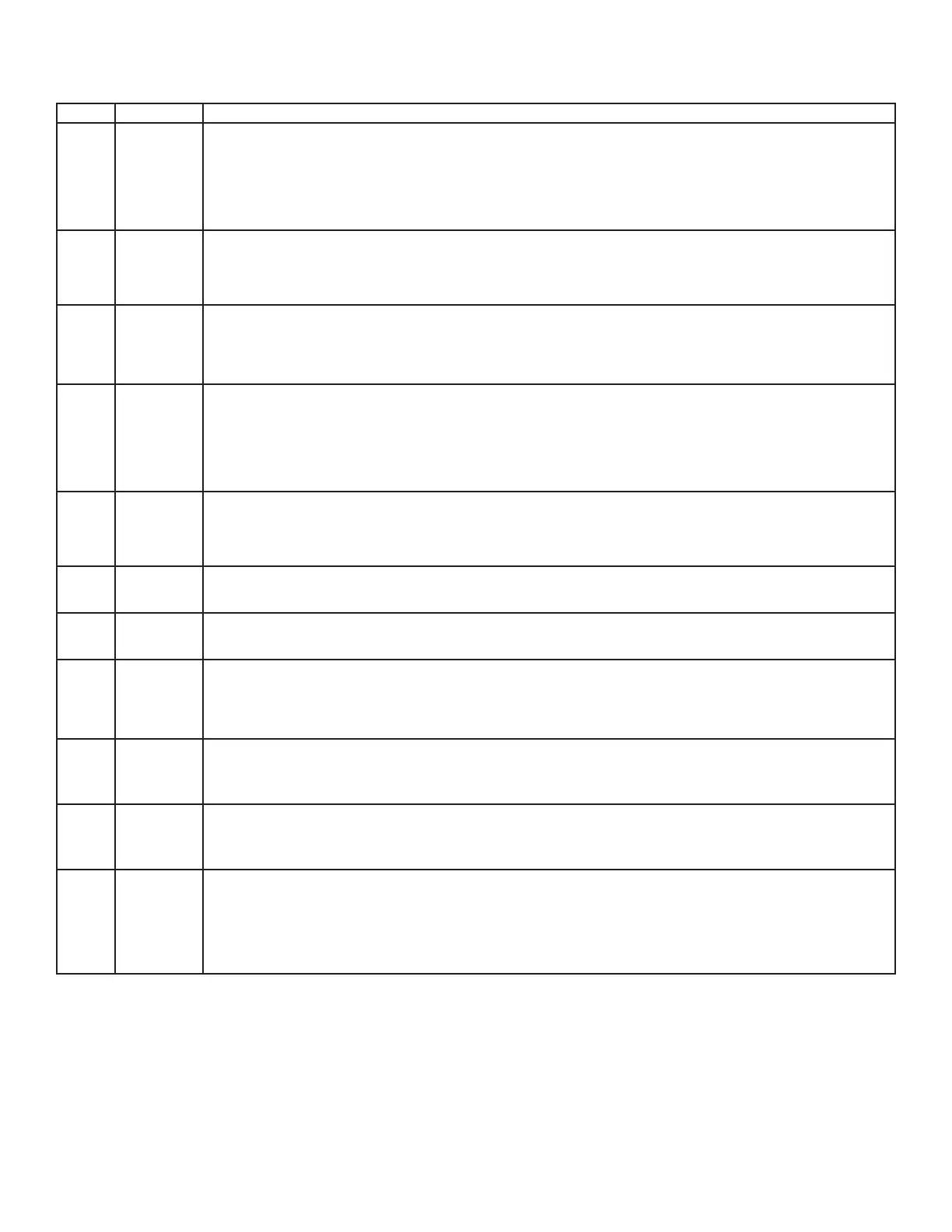

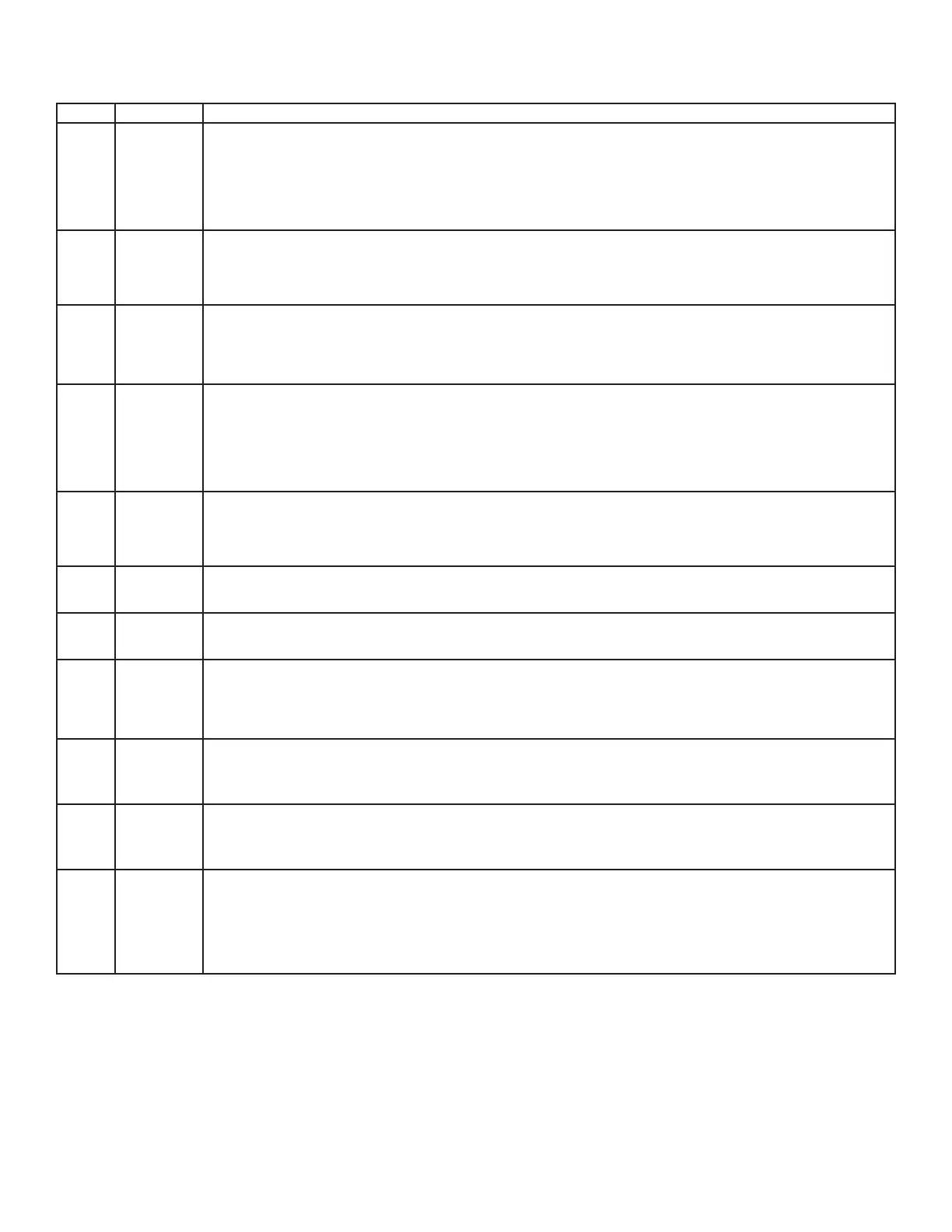

TROUBLESHOOTING CHART

Code(s) Description Action

22, 23 Fill problems • Ensure manual water valves are fully open.

• Check if water strainers on solenoid valve assembly are clogged.

• Check for obstructions inside inlet water hoses.

• Ensure solenoid valves do not leak when the valves are de-energized and the washer is powered down.

• Measure coil resistance for both valves; if outside range (1000–1250 ohms at room temp.), replace solenoid valve assembly.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM, OR FOR ERROR CODE 23:

• Replace solenoid valve assembly.

31 Drain • Ensure pump strainer is clean and free of debris.

problems • Check for obstruction inside the drain hose.

• Check pump impeller blades and bearing; if evidence of blade damage or seized bearings are present, replace the pump.

• Check electrical connections at the pump motor and harness.

• Measure pump motor resistance; if outside range (9–14 ohms at room temp.) replace the pump.

38, 39 Dispenser • Check for obstruction in dispenser mechanism and linkages.

problems • Check electrical connections at dispenser motor feedback switch and in the harness.

• Check electrical connections of water valves in the harness.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

• Replace dispenser motor assembly.

42, 44, 46 Motor Drive • Ensure all 4 shipping bolts have been properly removed.

47, 48, 49 operation • Remove all foreign objects that may be lodged between inner and outer basket.

above design • Look for signs of seized bearing(s) on basket and drum motor, replace components as necessary.

limits • Inspect condition and mounting of door gasket, replace and re-mount as necessary.

• Ensure inner basket (drum) can rotate freely.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

• Replace motor drive or drum motor.

43, 4A, Motor Drive • Measure AC outlet voltage, ensure correct range (102V to 132V AC).

4B, 4C, internal • Check electrical connections at the drum motor, motor drive.

50, 52, problems • Check harness integrity between main control and motor drive.

53, 54 • Unplug the unit, wait 30 seconds, restart the unit.

• If the fault persists and re-appears – replace the motor drive.

55, 56 Main Control • Replace the main control.

internal

problems

57, 58, Main Control • Unplug the unit, wait 30 seconds, re-start the unit.

71 internal • If the fault persists and re-appears – replace the main control.

problems

60, 61 DOOR LOCK • Check integrity of wiring and connections between main control and DOOR LOCK mechanism.

63, 64, assembly • Investigate DOOR LOCK mechanism, check door microswitch operation, lock and unlock solenoid continuity, contact integrity;

problems replace DOOR LOCK mechanism if necessary.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

• Replace the main control.

65, 80, Water Level • Check integrity of wiring and connections between main control and Water Level Sensor.

81, 82 Sensor • Check integrity of Water Level Sensor, replace if necessary.

problems

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

• Replace the main control.

66, 67 Water • Check integrity of wiring and connections between main control and Thermistor Assembly.

Temperature • Using ohmmeter, measure Thermistor resistance; if outside expected range, replace Thermistor Assembly.

Sensor

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

problems

• Replace the main control.

62 System • Check integrity of wiring and connections, look for insulation breakdown and short circuit conditions on the harness, replace

Contact harness if necessary.

Failure • Check integrity and electrical connections of all loads (heater, pump, pressure switch, door lock, solenoid valves,

dispenser motor), replace respective components if necessary.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

• Replace the main control.

7

FOR SERVICE TECHNICIAN ONLY—DO NOT REMOVE OR DESTROY

175D6149P002

Loading...

Loading...