18

11.8—Lubrication

Proper lubrication is important for maintaining reliable circuit

breaker performance. The ML-20 mechanism uses bearings

which have a synthetic lining in some locations. These

bearings do not require lubrication to maintain low friction, but

lubrication does not harm them and oiling lightly is

recommended. Sleeve bearings are used in some linkage

locations and needle or roller bearings are used for low friction

on trip shaft and close shaft.

Bearings are lubricated during factory assembly with grease

and oil, but all lubricants have a tendency to deteriorate with

age. Providing a fresh lubricant supply at periodic intervals is

essential to proper breaker operation, especially where

frequent operation may have forced lubricant out of the

bearing surfaces. Apply a few drops of light synthetic machine

oil such as Mobile 1 at each bearing. Apply a coat of

0282A2048P009 grease on the four corners of the closing

spring guide where it enters inside the spring.

Metal-to-metal contact surfaces should be cleaned and

lubricated with 0282A2048P009 grease to provide cleanliness

and prevent oxidation.

Electrical primary contact surfaces also require periodic

lubrication to inhibit oxidation and minimize friction. At each

inspection and maintenance interval, do the following:

1. Wipe clean and coat lightly with grease

(0282A2048P009) all silvered primary contact surfaces

such as the movable contact rod of the interrupter and

the primary disconnect fingers.

2. Clean and coat lightly with grease the pins of the

secondary disconnect coupler.

11.9—Recommended Maintenance

The following operations should be performed at each

maintenance check:

1. Perform a visual inspection of the breaker. Check for

loose or damaged parts.

2. Perform slow closing operation described under

MECHANICAL CHECKING AND SLOW CLOSING.

3. Check the erosion indicator and the wipe and gap as

described under DIMENSIONAL CHECKS.

4. Perform the vacuum interrupter integrity test as

described under ELECTRICAL CHECKS.

5. Lubricate the breaker operating mechanism as described

under LUBRICATION.

6. Check the electrical operation using the test cabinet (if

available) or the test position in the metalclad switchgear.

CAUTION: REPEATED OPERATIONS AT A RATE EXCEEDING

TWO PER MINUTE MAY CAUSE CHARGING MOTOR

OVERHEATING AND SUBSEQUENT MOTOR FAILURE.

7. Examine the movable contact rod of the vacuum

interrupter. With the breaker open, wipe the lubricant off

the rod and examine the silver surface. The rod should

have a burnished appearance without copper appearing

through the silver. If copper is visible at more than one

location per pole, or if the silver plating is torn, the

interrupter assembly should be replaced. Re-lubricate

movable contact rod with 0282A2048P009 grease

8. If desired, perform the additional electrical tests (Megger,

Primary and Secondary High Potential, and Primary Circuit

Resistance). See ELECTRICAL CHECKS.

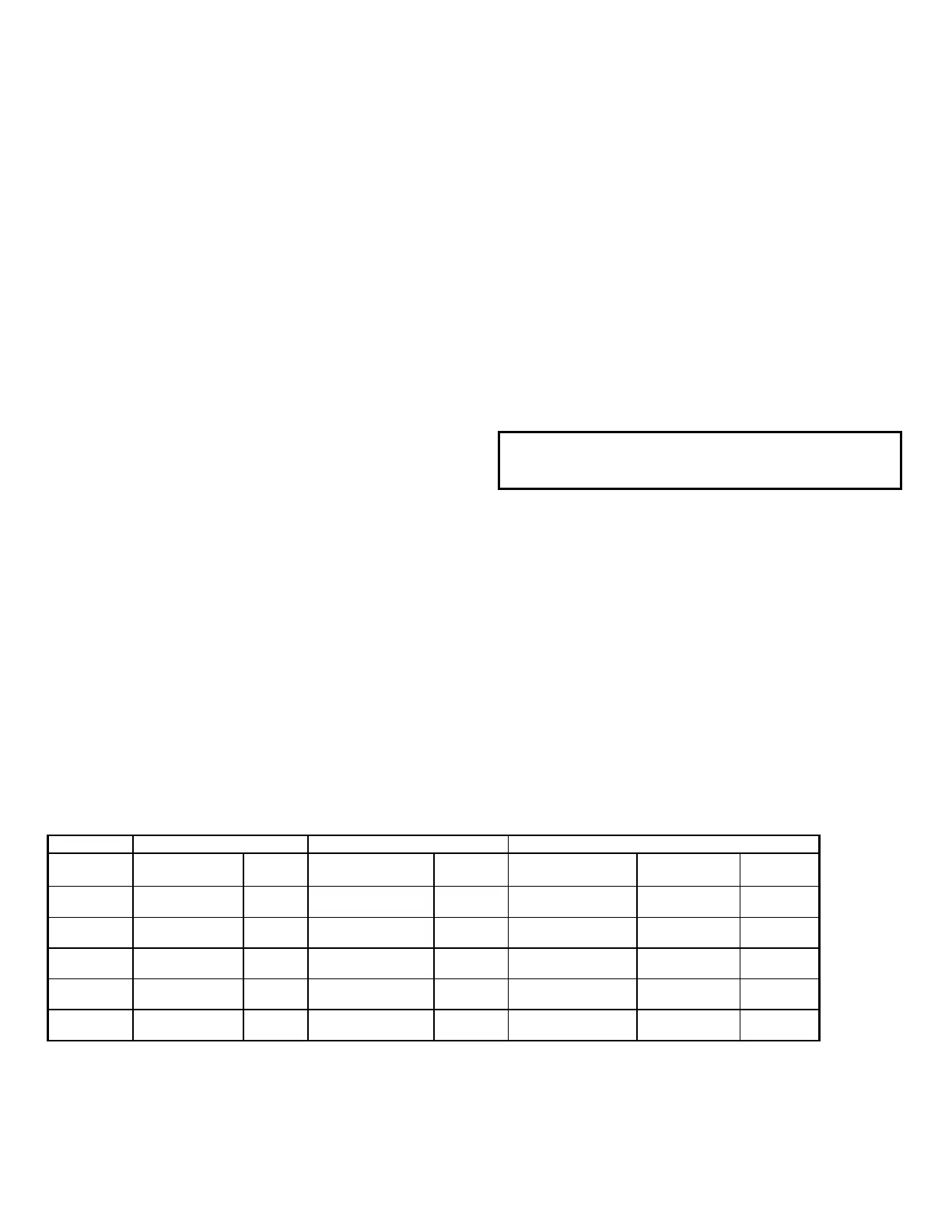

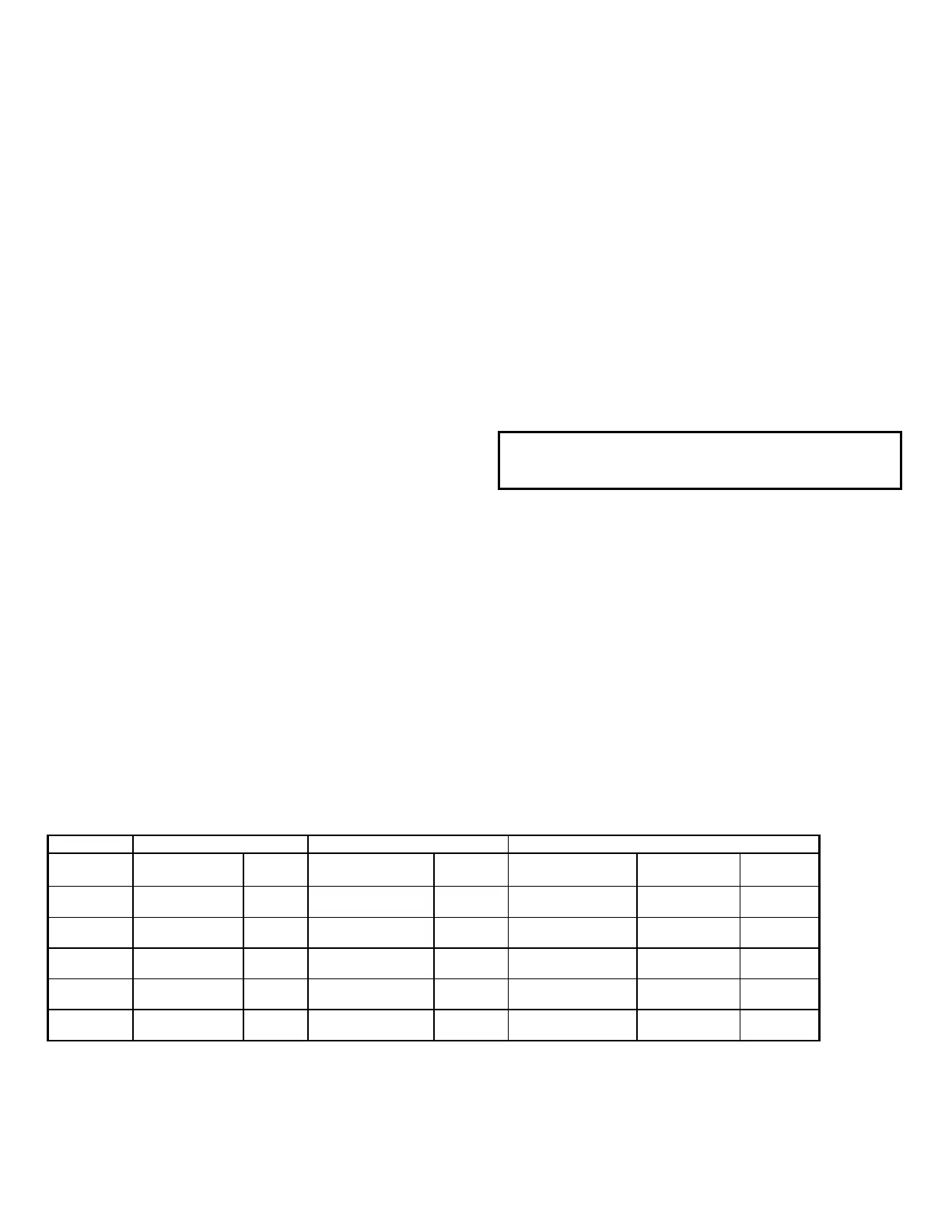

Nominal Charge Motor Close Coil Trip Coil

Control

Voltage

Part No.

Range

Part No.

Range

Part No.

(5 cycle)

Part No.

(3 cycle)

Range

48 VDC 0177C5050G009 36-56 0209B8103G008 38-56 0209B8104G001 0209B8104G0

01

28-56

125 VDC 0177C5050G007 90-140 0209B8103G009 100-140 0209B8104G002 0209B8104G0

07

70-140

250 VDC 0177C5050G008 180-280 0209B8103G010 200-280 0209B8104G003 0209B8104G0

0…6

140-280

120 VAC 0177C5050G047 104-127 0209B8103G011* 104-127 0209B8104G004** N/A (Cap. Trip)

104-127

240 VAC

0177C5050G008

208-254

0209B8103G012*

209-254

0209B8104G004**

N/A

(Cap. Trip)

208-254

*With rectifier

**With Capacitor Trip Module

Table 1. Control Devices and Voltages

Loading...

Loading...