5

SECTION 2—Description

2.1—General

This section contains a description of the PowerVac

®

vacuum

circuit breaker. It also describes the functions of the electrical

and mechanical systems.

2.2—Summary Description

The PowerVac

®

vacuum circuit breaker uses sealed vacuum

power interrupters to establish and interrupt a primary circuit.

Primary connections to the associated metalclad switchgear are

made by horizontal bars and disconnect fingers, electrically and

mechanically connected to the vacuum interrupters. Molded

interrupter supports, one per phase on a three-phase circuit

breaker, provide mountings for the primary bars, interrupters,

current transfer fingers, and heat dissipation fins (where used).

The operating mechanism provides direct motion at each phase

location in order to move the movable contact of the vacuum

interrupters from an open position to a spring-loaded closed

position and then back to the open position on command.

The ML-20 mechanism is of the stored-energy type and use a

gear motor to charge a closing spring. During a closing operation,

the energy stored in the closing spring is used to close the

vacuum interrupter contacts, compress the wipe springs which

load the contacts, charge the opening springs, and overcome

bearing and other friction forces, The energy then stored in the

wipe springs and opening springs will open the contacts during an

opening operation.

Closing and opening operations are controlled electrically by the

metalclad switchgear or remote relaying. Mechanical control is

provided by manual close and trip buttons on the circuit breaker.

The closing spring may be manually charged, and a method for

slow-closing the primary contacts is available. The mechanism will

operate at the ac or dc voltage indicated on the circuit breaker

nameplate.

Mechanical and electrical interlocks are provided and are

described in para 4.2, Interlocks

SECTION 3—Receiving, Handling and Storage

3.1—Receiving

A. Equipment Packages

Every package leaving the factory is plainly marked with the case

number, requisition number, and customer’s order number. If the

equipment has been split for shipment, the section numbers of

the equipment enclosed in each shipping package are identified.

NOTE: To avoid loss of any parts when unpacking, the contents

of each container should be carefully checked against the packing

list before discarding the packing material.

Contents of each shipping package are listed on the Master

Packing List. In addition, this list includes the number of the

shipping crate in which miscellaneous parts needed to install and

operate equipment (such as hardware, contact lubricant, touch-up

paint, breaker closing devices, etc.) are located. Normally, such

devices are packed in a cardboard carton.

B. Inspecting for Damage

All equipment leaving the factory is carefully inspected and

packed by personnel experienced in the proper handling and

packing of electrical equipment. Upon receipt of any equipment,

immediately perform a visual inspection to ascertain if any

damage has been sustained in shipping or if there are any loose

parts.

C. Filing a Claim

If any damage is evident, or indication of rough handling is

visible, file a claim for damage at once with the transportation

company and notify the nearest GE Company Sales Office

immediately. Information on damaged parts,

part number, case

number, requisition number, etc., should accompany the claim.

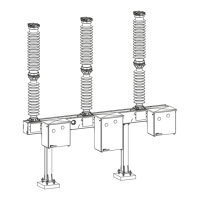

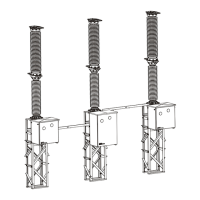

3.2—Handling

When lifting the breaker, use of the specially designed lift truck is

recommended. If it is necessary to lift the breaker with a hoist use

four 1/2 inch diameter hooks rated at least 500 pounds each.

Lifting holes are provided in the four corners of the frame

members. (See figure 2) Use a spreader wider than the breaker

to prevent slings from contacting the interrupter supports.

3.3—Storage

It is recommended that the breaker be put immediately in its

permanent location. If this is not possible, the following

precautions must be taken to assure proper breaker storage.

1. The breaker should be protected against condensation,

preferably by storing it in a warm dry room of moderate

temperature such as 40° - 100°F. Circuit breakers for outdoor

metalclad switchgear should be stored in the equipment only

when power is available and the heaters are in operation to

prevent condensation.

2. The breaker should be stored in a clean location, free from

corrosive gases or fumes; particular care, for example,

should be taken to protect the equipment from moisture and

cement dust, as this combination is present at construction

sites and has a very corrosive effect on many parts.

3. Rollers, latches, etc., of the operating mechanism should

be coated with 0282A2048P009 grease to prevent

rusting.

If the breaker is stored for any length of time, it should be

inspected periodically to see that rusting has not started and

to ensure good mechanical condition. Should the breaker be

stored under unfavorable atmospheric conditions, it should be

cleaned and dried out before being placed in service.

Loading...

Loading...