immediately, however if the compressor has run for less

than 6 minutes it will be prevented from starting for the

remainder, i.e. if run for 4 minutes, there will be a 2 minute

delay on the next start. This is non adjustable.

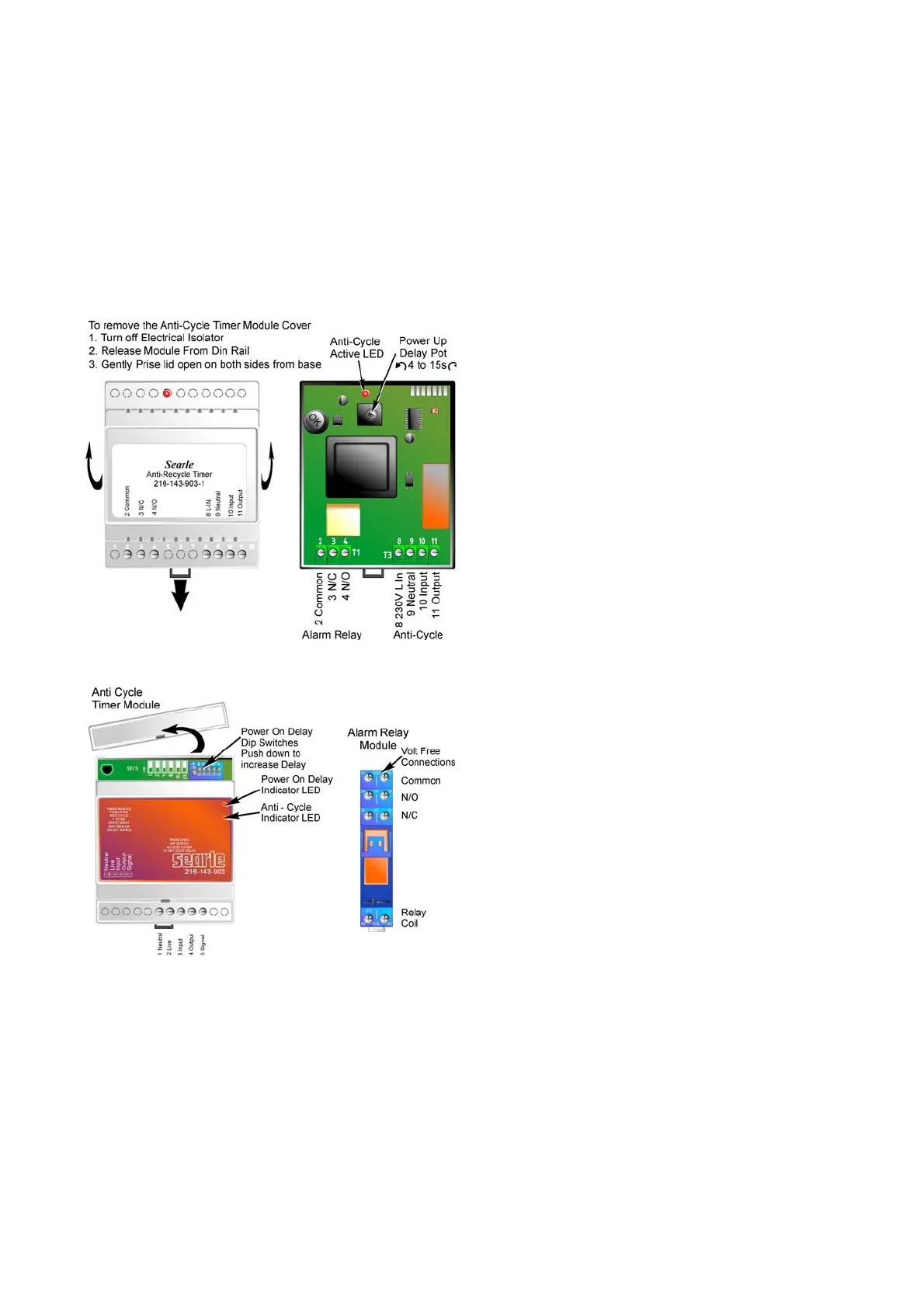

Delay on Power Up start Function

The timer also has an adjustable delay for start up after a

mains power failure. This function may be used to give a

set delay before the compressor starts, and can be set

differently on multiple units to prevent an over current on

the mains supply, and possible tripping of the mains

breaker.

To adjust the delay see the diagrams below.

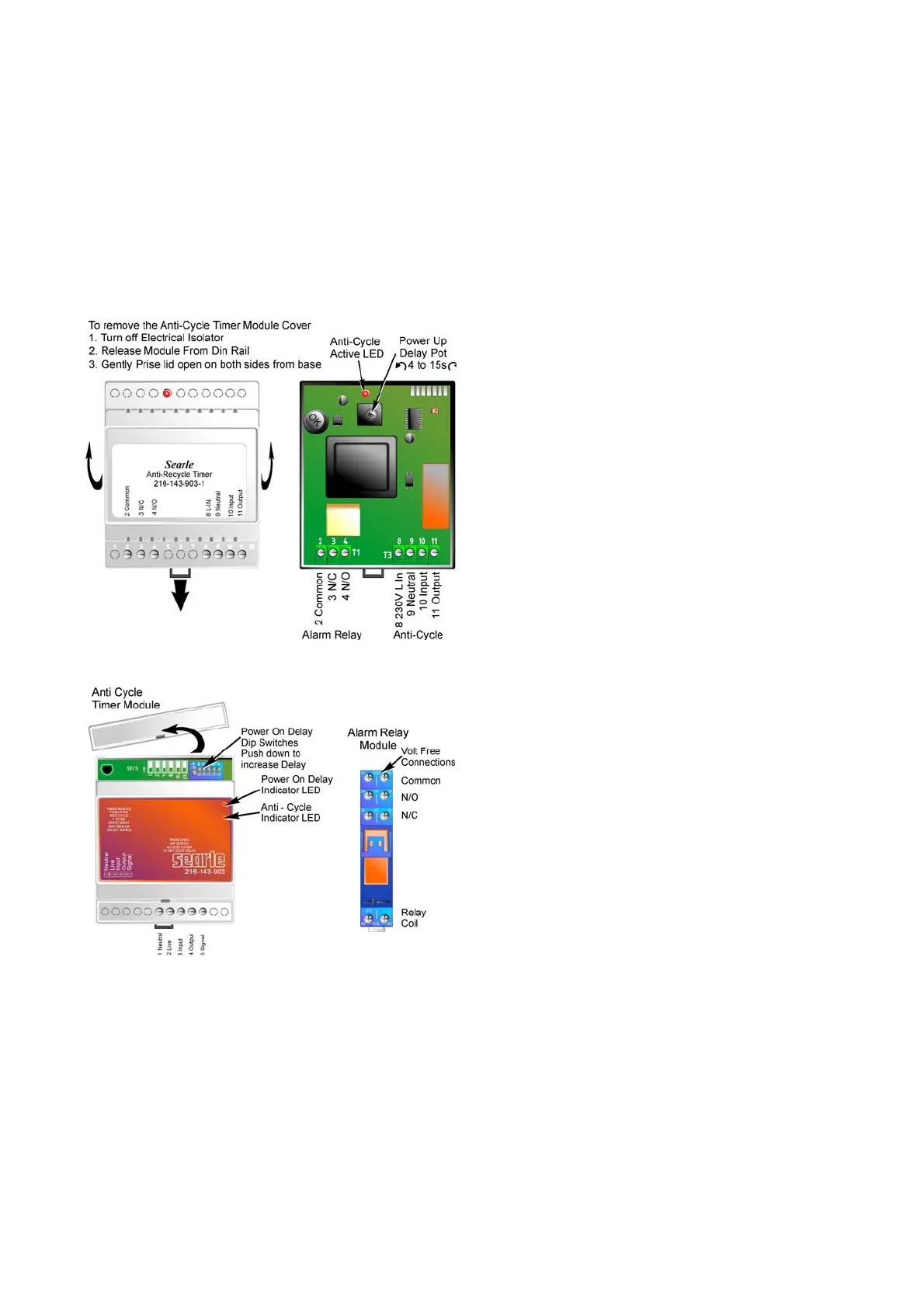

The modules have indicator LED’s which illuminate when

the delay timer is active.

Units with Combined Alarm Relay and Anti Cycle

Units with separate Anti-Cycle / Alarm Module

h) Volt Free Alarm Relay – Standard on NSQ/NCQ,

optional on NSE NCE, with electrical options W, T & E.

Units are fitted with a volt free relay, either mounted on a

separate din rail, or integrated in the Anti-Cycle timer, (see

section ‘g’). The relay will energise when ‘Healthy’ and will

de-energise on the following faults :-

Mains Power Loss, HP Trip, Compressor Overload Trip.

The relay is a changeover type with volt free terminals for

Normally Open, Normally Closed and Common

connections. Any customer connection to these terminals

must not exceed a load of 8A resistive (AC1) at 230V.

‘L’ version units only

i) DTC - 'LX/S' models use ZF scroll compressors.

ZF model compressors require liquid injection to keep

discharge temperatures within safe limits. The compressor is

equipped with a sensor bulb, which is installed, in the top cap

of the compressor. The bulb senses discharge temperature

and enables controlled liquid injection as temperature rises

above the factory set point. The valve is connected with a

flexible hose to the liquid line via a schraeder connection.

j) Klixon - discharge temperature protector, switches the

compressor off if the discharge temperature exceeds a pre-set

maximum (auto re-set).

k) EVI Vapour Injection Solenoids – ‘LV’ models only.

Units are fitted with a Plate Heat Exchanger to super sub cool

the liquid from the condenser, and provide vapour injection to

the compressors. A solenoid valve on each compressor

vapour injection port is slaved to the compressor contactors

and operates when the compressor runs.

All units

l) Pressure Relief Valve - fitted in the side of the liquid

receiver. If the unit is not located externally in open air the

relief valve outlet must be piped away to open air.

Regular maintenance is required see section 6.

Maintenance Every 3-6 Months.

3. EVACUATION AND CHARGING

Before operating the unit for the first time, check that all

guards, motors, mountings and electrical covers are secure,

and that fans rotate freely. The unit has been leak tested,

dehydrated and filled with a holding charge of "dry air" during

manufacture.

The entire system should be evacuated prior to charging as

follows:

• The right hand panel should be removed to provide access

to the compressor shut off valves with service ports.

• Connect a vacuum pump to the 1/4" flare connections on

each compressor shut-off valve.

• These valves will be in a fully back-seated position in the

unit as supplied. The valve spindles should be screwed in a

few turns to open up the ports.

• Evacuate the system to below 225 microns (0.3mbar). The

pump should be isolated and system pressure monitored. A

rapid continuous rise would indicate a leak in the system.

• During the evacuation process, the crankcase heater

should be switched on.

Note: To ensure that compressor is not operated during

evacuation, the compressor overloads / manual motor starters

must be in the off position.

DO NOT START THE COMPRESSOR UNDER

ACUUM. NEVER RUN COMPRESSOR IF CONTAINING

AIR .

The unit should be charged with the specified refrigerant

(N2CQ ‘L’ Units R404A, ‘N2CQ M’ Units

R404A/R407C/R134A), until the sight glass is just clear at the

normal operating condition. If after charging the unit is left with

the power supply turned off, turn on the power supply for a

minimum period of three hours before the unit is switched on.

This will ensure that the compressor sump is warm and free

from liquid refrigerant.

IMPORTANT

N2CQ Scroll compressors, like several other types of

compressor, will only compress in one rotational direction.

Three-phase compressors will rotate in either direction,

depending upon phasing of the power to T1, T2 and T3. Since

there is a possibility of connecting power in such a way as to

cause rotation in the reverse direction, it is important to check

this. Verification of rotation direction can be made by

observing that suction pressure drops and discharge pressure

rises when the compressor is energised. Reverse rotation

results in a sound level above that of the correct rotation

direction, as well as a substantially reduced current draw.

4

Loading...

Loading...