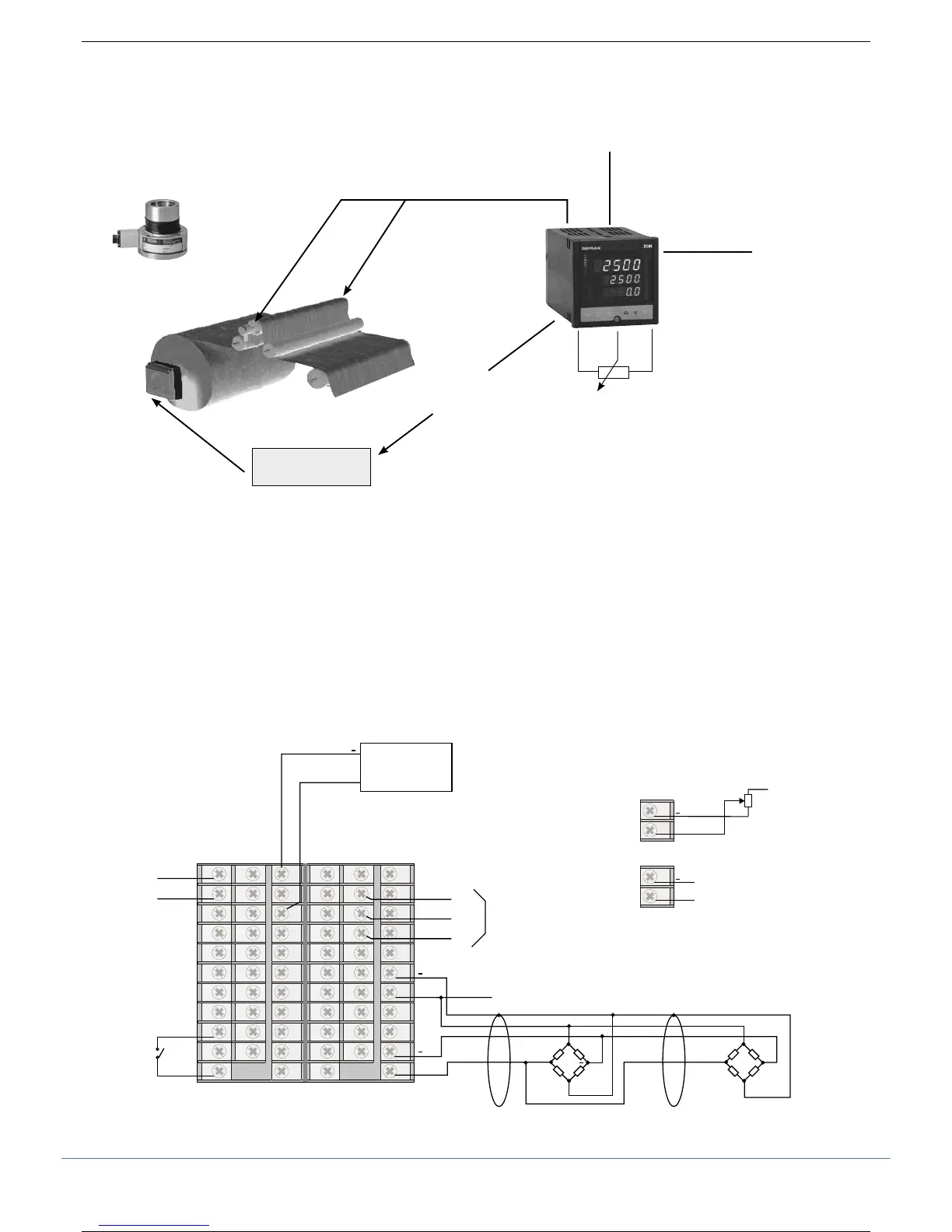

3. ROLLER TENSION CONTROL

Model 2500-0-0-0-0-2-1

PAS = 32

The basic model 2500-0-x-x-x-x-x with one main input accurately controls roller tension on a winding line.

Tension is measured by 2 load cells with 2mV/V sensitivity connected in parallel, powered at 10Vdc by the instrument’s auxiliary

power supply.

Given a setpoint, the instrument keeps roller winding constant.

The 2500 control output controls the drive that controls winder motor speed.

Tension control can be adjusted via a digital input configured to select Local/Remote SP and an external potentiometer powered by

the instrument.

A second remote input, configured to receive line speed, lets the instrument start in Automatic with a percentage of power on the con-

trol output, thereby preventing strong jerks on the winding material.

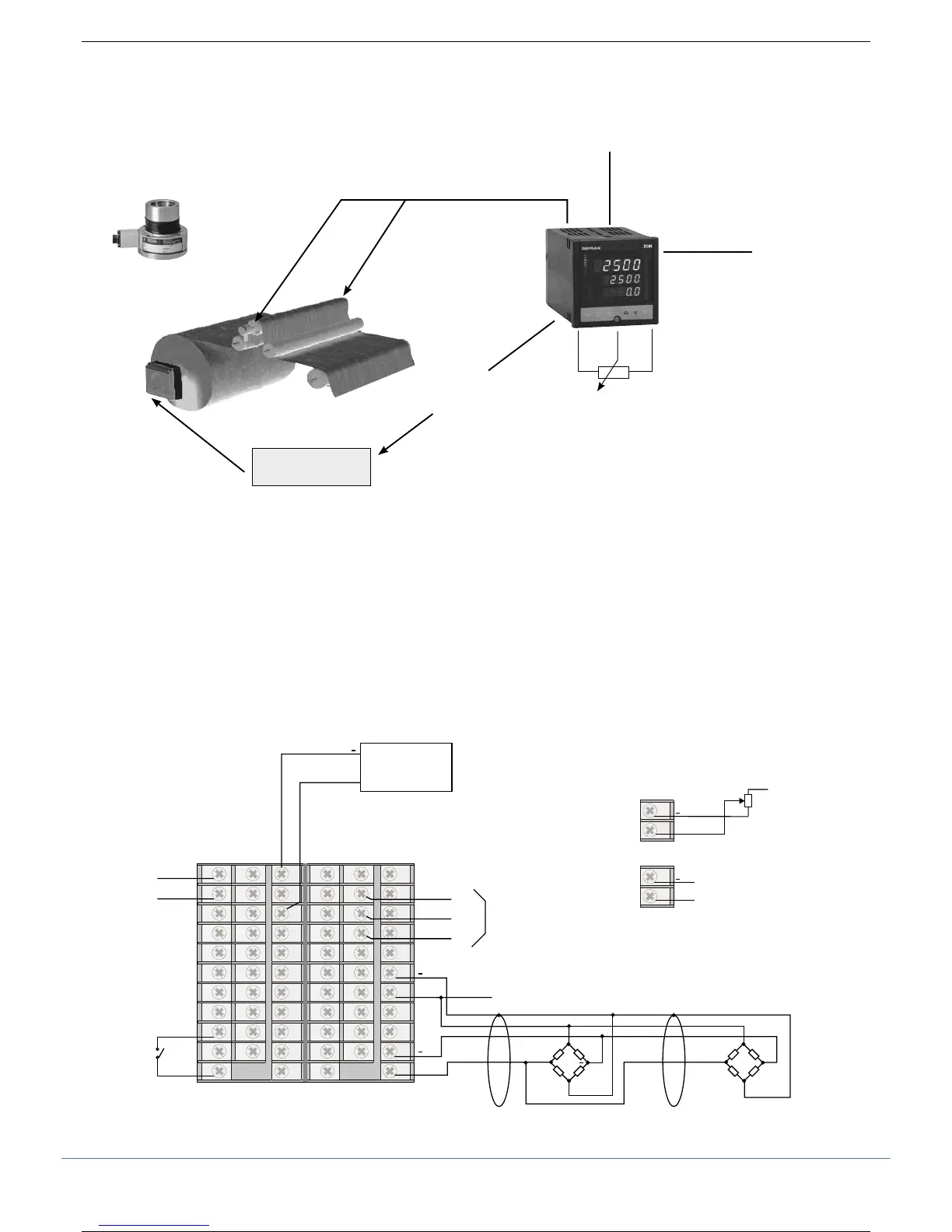

Drive

TR Load Cell

TR

TR

Main input 1

Auxiliary analog input 3

Dialog with

PLC or supervi-

sion unit (if any)

Tension control

Remote SP

(through potentiometer)

Auxiliary analog input 4

Control output

0...10V

Line speed (0-10Vcc)

BA

1

11

24

33

1

11

22

12

2

3

4

5

6

7

8

9

10

25

26

27

28

29

30

31

32

13

14

15

16

17

18

19

20

21

10

9

8

7

6

5

4

3

2

22

12

13

14

15

16

17

18

19

20

21

24

33

25

26

27

28

29

30

31

32

GND

A (data +)

B (data -)

~

~

Setpoint LOC / REM

CO1

- Exc

+ Exc

- Exc

+ Exc

10

11

8

9

+

+

+

+

+

+

+

+

Serial

line

Drive

Power

supply

IN3

Line speed reference

IN4

Tension set potentiometer

Vpot (10Vdc)

Vpot (10Vdc)

1980291G_MHW_2500_08-2010_ENG

19 / 77

Loading...

Loading...