www.gemu-group.com68 / 76GEMÜ 1436 cPos

20 General information regarding control engineering

Proc I: T

n

Proc D: K

d

Proc T: T

v

Interpretation of the controller parameters according to

Ziegler-Nichols:

The following process is intended to help to adapt the control-

ler to the controlled system (however this process can only be

implemented on controlled systems where it is possible to let

the controlled variable oscillate of its own accord).

- Set the values for Kp (Proc P) and Tv (Proc T) to their min-

imum and the value for Tn (Proc I) to 0 (this leads to the

smallest possible effect of the positioner).

- Enter the desired set value manually in manual mode.

- Slowly increase Kp (Proc P) (decrease Xp), until the con-

trolled variable starts to oscillate harmoniously. Ideally, the

control circuit should be stimulated to oscillate by erratic

set value changes during the Kp adjustment.

- Note the Kp value thus obtained as a critical proportional

action factor Kp,krit.

- Following this, determine the duration of an oscillation as

Tkrit. If possible, use a stopwatch to measure several oscil-

lations and use the arithmetic mean as Tkrit.

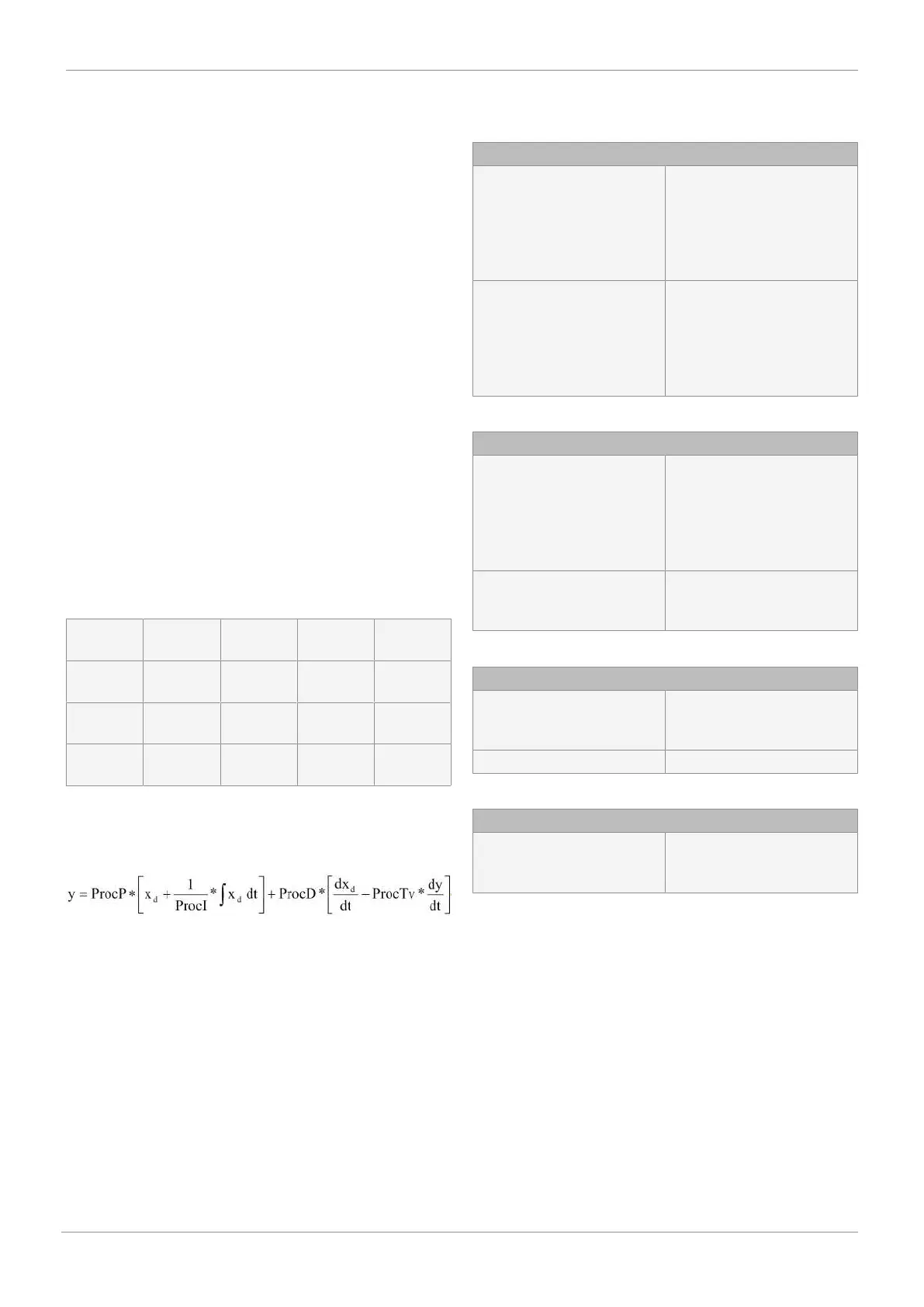

- Use the values thus determined for Kp,krit and Tkrit to cal-

culate the missing Kp, Tn and Tv parameters according to

the following table.

Kp = Proc

P

Tn = Proc I Proc D Tv = Proc

T

P 0.50 x

Kp,krit

0 0 0

PI 0.45 x

Kp,krit

0.85 x Tkrit 0 0

PID 0.59 x

Kp,krit

0.50 x Tkrit 0.59 x

Kp,krit

0.12 x Tkrit

- If necessary, re-adjust the Kp and Tn values a little until the

control system shows satisfactory behaviour

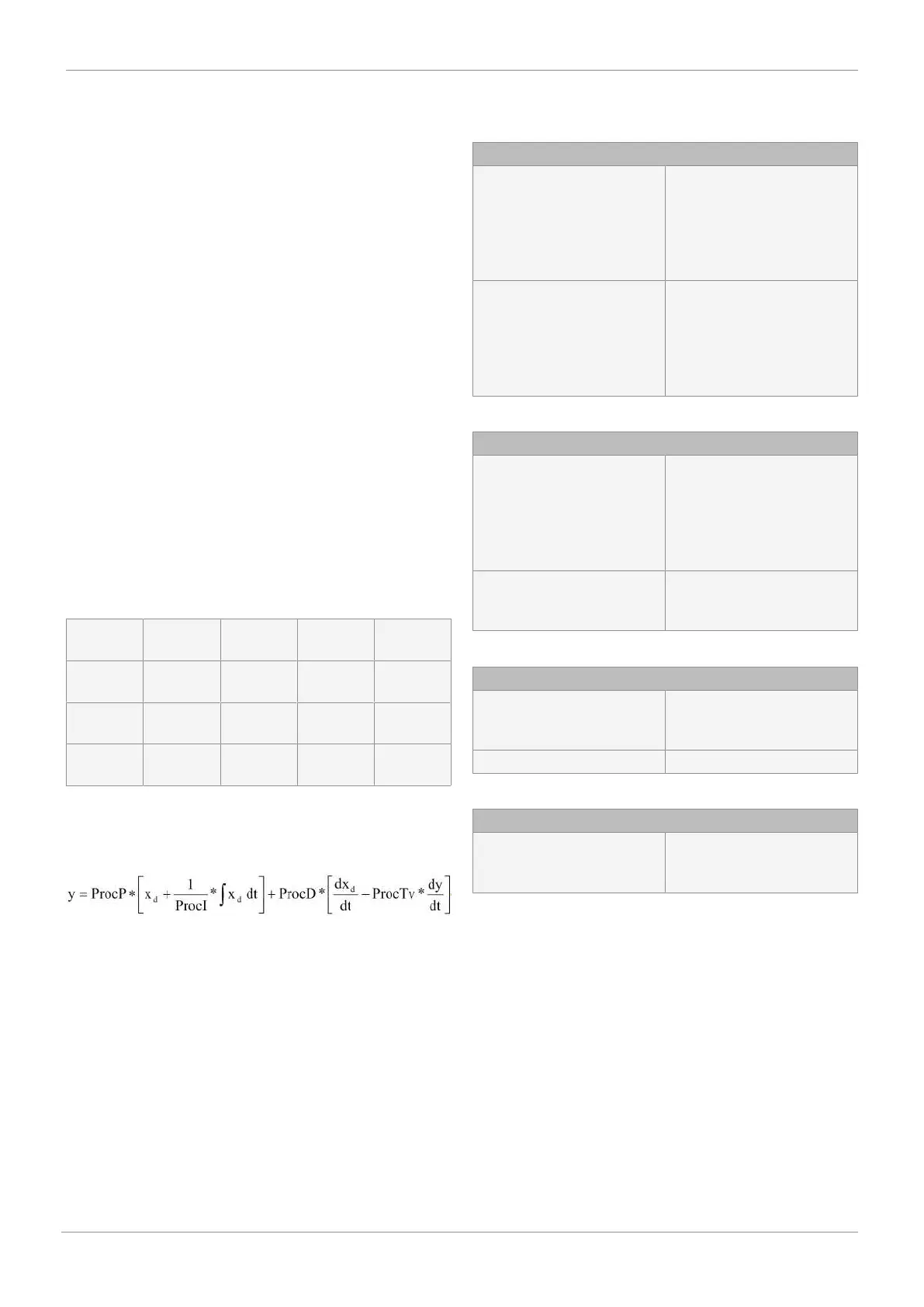

20.5 Differential equation of the product

20.6 Effects of the positioner parameters on the

automatic control system

Proc P:

Larger: The controller controls more

quickly but tends to oscillate

and is less precise in its con-

trol. The set value is achieved

in larger steps by increasing

the manipulated variable

Smaller: The controller controls more

slowly as the set value is

achieved in smaller steps by

reducing the correcting vari-

able. Control is more accur-

ate.

Proc I:

Larger: The positioner reacts more

slowly to changes to actual

values. Proc I should be in-

creased for actual value

sensors with relatively slow

output signals.

Smaller: The controller reacts more

quickly to changes to actual

values.

Proc D:

Larger: Slows down the manipulated

variable y when moving to the

set value. Control is slower.

Smaller: Set value is achieved faster.

Proc T:

Larger: The system deviation has a

longer effect although set

value = actual value

Loading...

Loading...