653, 654

16 / 28

Important:

If the diaphragm is not screwed

into the adapter far enough, the

closing force is transmitted directly

onto the diaphragm pin and not

via the compressor. This will cause

damage and early failure of the

diaphragm and thus leakage of the

valve. If the diaphragm is screwed

in too far no perfect sealing at the

valve seat will be achieved. The

function of the valve is no longer

ensured.

Important:

Incorrectly mounted diaphragm

may cause valve leakage /

emission of medium. In this case

remove the diaphragm, check the

complete valve and diaphragm and

reassemble again proceeding as

described above.

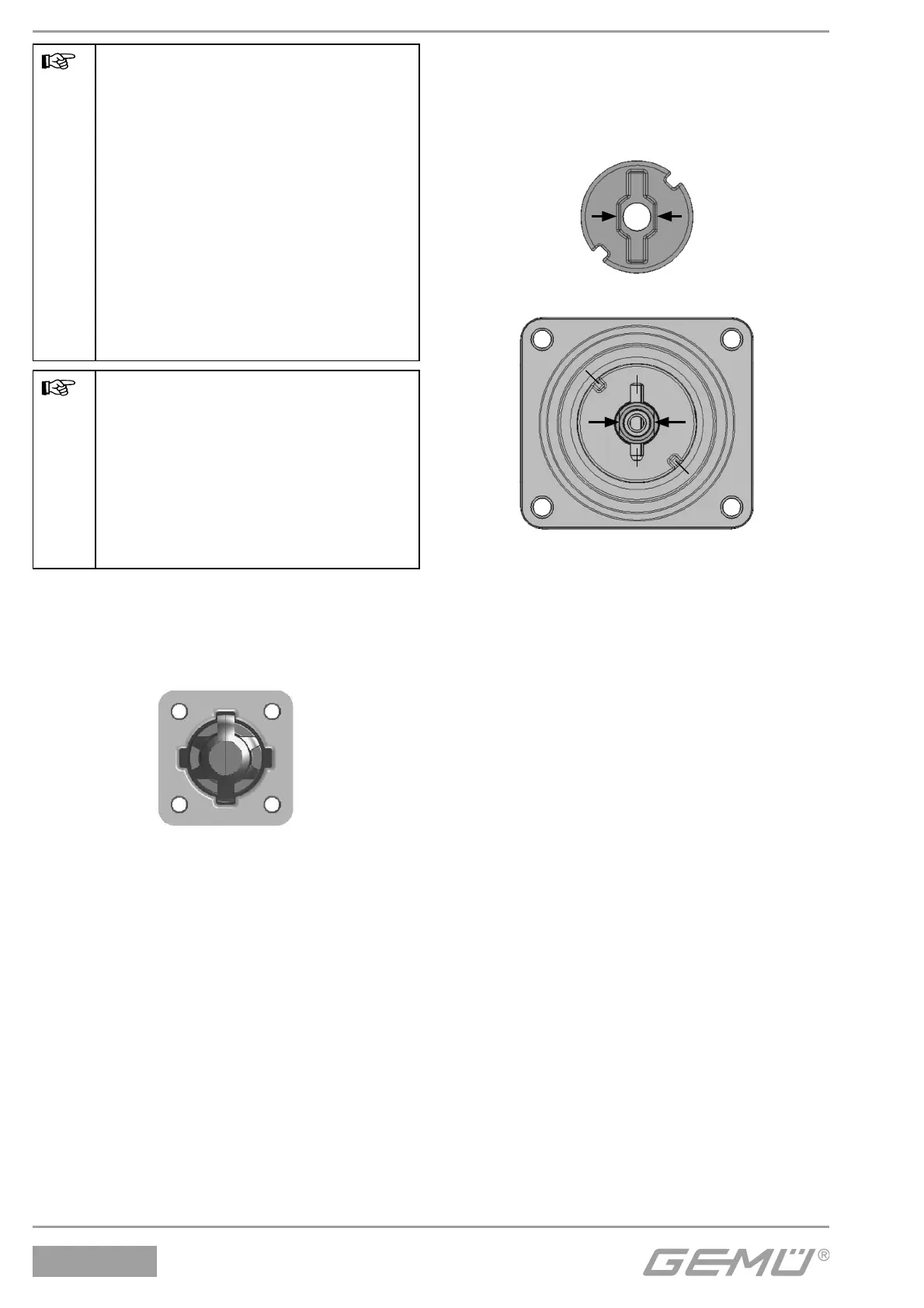

Diaphragm size 8:

The compressor is fixed to the spindle.

Compressor and bonnet flange seen from

below:

Diaphragm size 10:

The compressor is loose.

Compressor and bonnet flange seen from

below:

B

D

C

D

B

C

A

A

Pict. 1

Pict. 2

Anti-twist system of the spindle at the

compressor

A double flat (arrows picture 1) is fitted at

the end of the bonnet spindle to protect the

spindle against twisting. When mounting

the compressor, the double flat must be

in correct alignment with the recess of the

compressor back (arrows picture 2).

If the bonnet spindle is not in the correct

position, it must be turned to the correct

position. The position of A is offset by 45° to

the position of C.

Place the compressor loosely on the bonnet

spindle, fit the recesses D into the guides C

and A into B. The compressor must be able

to be moved freely between the guides!

Loading...

Loading...