- 6 -

COMMISSIONING

6 - VERIFICATIONS PRIOR TO COMMISSIONING

- Ensure that the installation has been issued with

a certificate of conformity granted by an approved

organisation (according to the installation stan-

dards),

- Check that the boiler is adequately adapted to the

gas used and that there are no gas leaks.

- Check that the boiler is filled with water and under

pressure (1.5 bar) and there are no leaks,

Never let the pressure drop below 1

bar.

- Check that the electrical connections of the boiler

are correct: 230 V, 50 Hz, earth connection com-

pliant, polarities correct,

- Check that the combustion products outlet is cor-

rectly assembled, that there are no leaks and no

obstruction,

- Check that the heating system ventilations are

not obstructed,

- Check that the condensate siphons of the flues

are filled with water,

- Check that the condensate outlet is connected

properly and there are no leaks.

- Check the system is totally cleaned and had been

cleaned and flushed in accordance with BS 7593.

Failure to do this may invalidate the warranty.

7 - USER INFORMATION

The heating engineer must inform the user about

the unit’s operating mode. In particular the user

must be informed about the function and the opera-

tion of the safety systems and the need for regular

servicing by a qualified person.

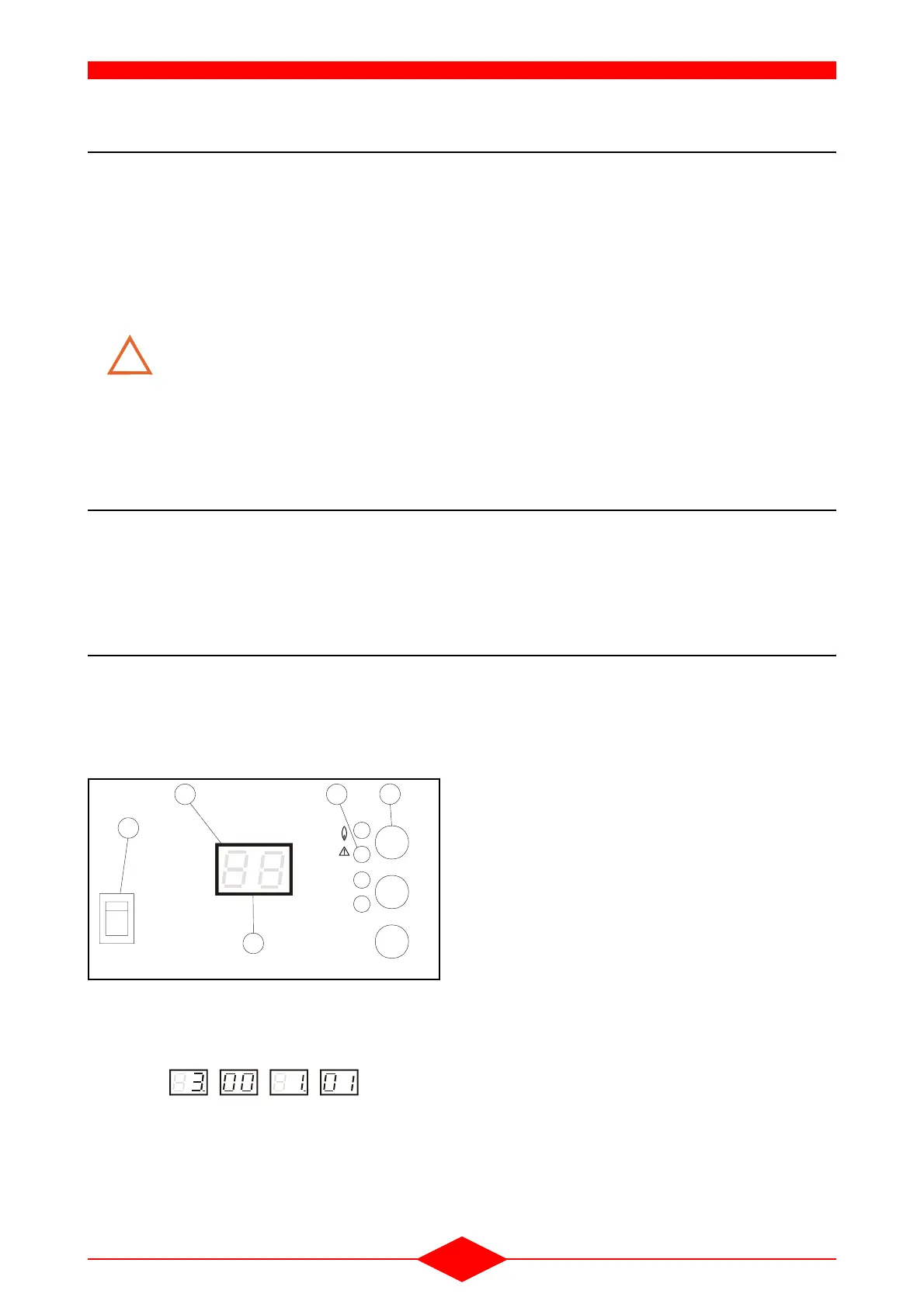

8 - COMMISSIONING

- Check that all the water stop valves and the gas

cock are open,

- Activate the boiler’s external electrical circuit-

breaker,

- Press button (14) to ON (Button illuminated).

• The following references will appear one after

the other on the boiler control panel display

(13),

For this example, this means that it is the ver-

sion 3.00 of the LMU management unit and

version 1.01 of the control interface.

When starting up the boiler, the LMU management

unit recognises all the accessories connected (sen-

sors, mixing valve, pumps, etc.) and automatically

checks the values and settings according to the type

of installation.

If a problem occurs, the LED “alarm signal” (11) is

on (red):

• Press RESET (10) to reset the boiler,

• If the alarm persists, consult the list of opera-

ting faults in chapter IV - OPERATING

FAULTS - page 17 - SERVICING MANUAL.

!

13

14

j

bar

Info

°C

Reset

10

11

13

T

H

I

-

8

1

-

0

0

Fig. 2

Loading...

Loading...