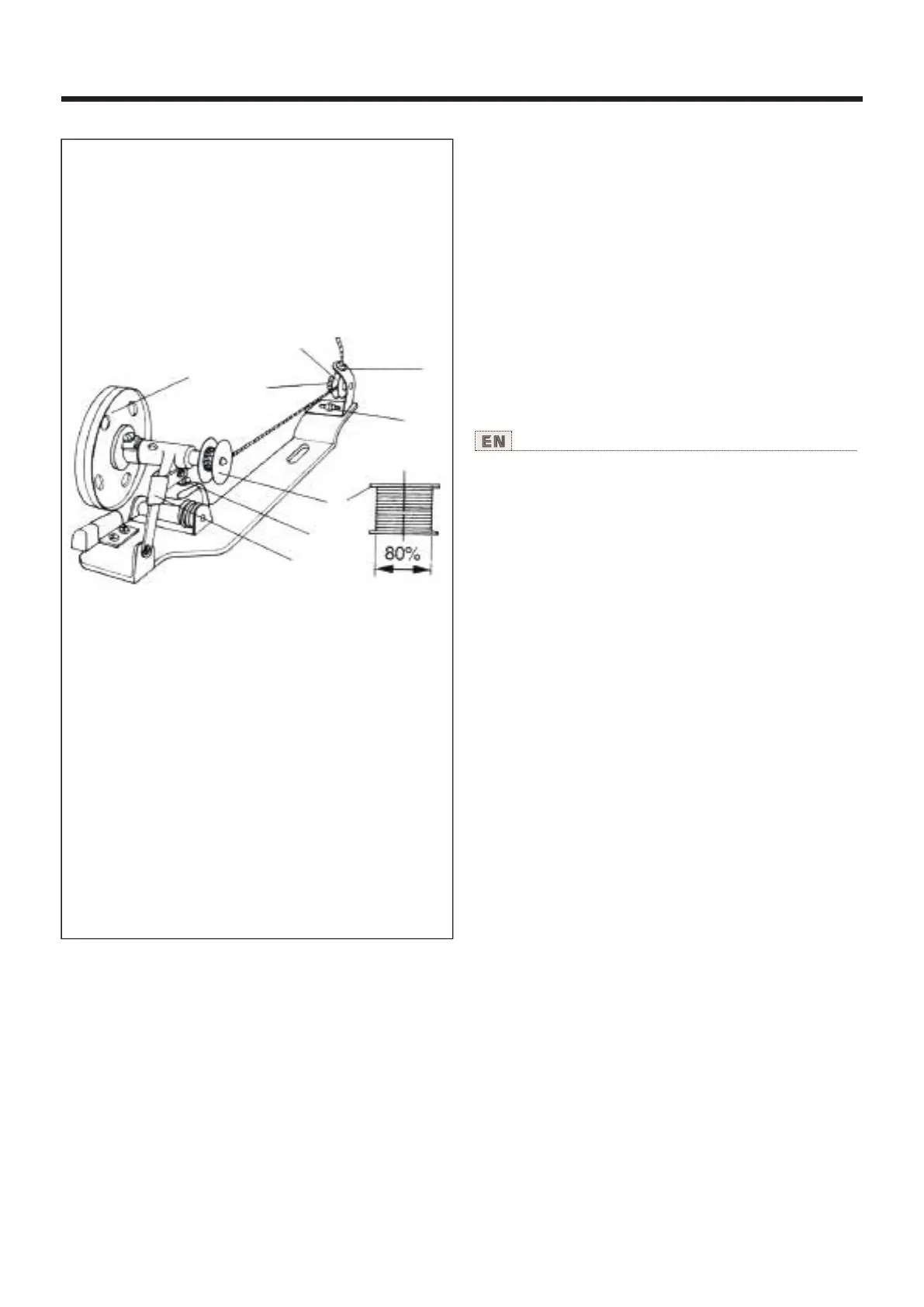

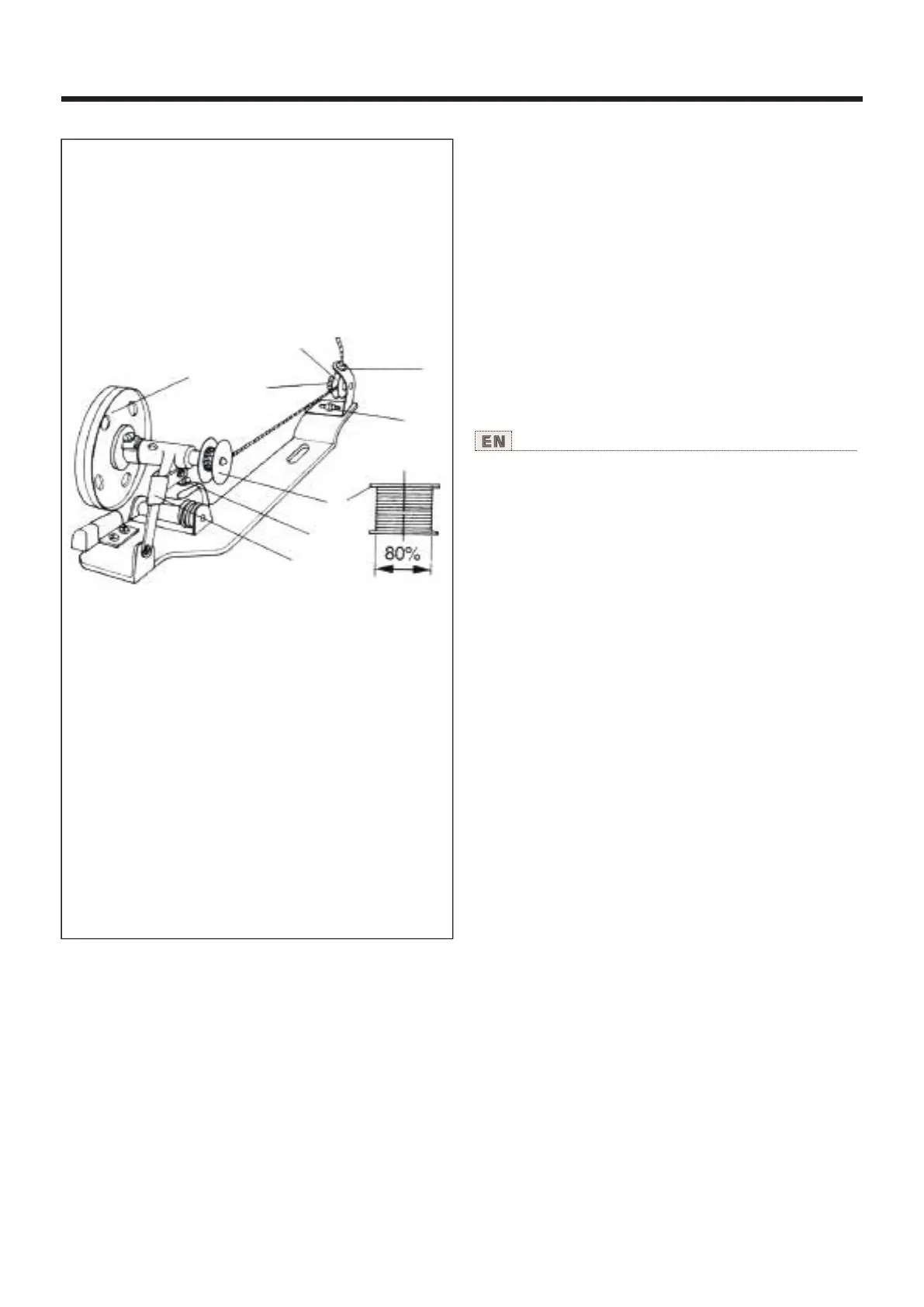

7.绕底线及调整 Winding and adjusting lower thread

A.绕底线

(1)把线从孔①中穿出,从夹线器②的后面绕到前面。

(2)把线拉到梭芯③,从底顺时针绕5-6圈。

(3)推杠杆④,让滑轮⑤触到V皮带后,启动机械。

(4)梭芯绕完底线后,滑轮⑤自动从V-皮带移开。

(5)梭芯绕底线量以80%左右为宜。

B.绕底线调整

(1)底线绕得不均匀时,松开螺丝⑥后左右移动进行

调整,然后重新拧紧螺丝⑥。

(2)顺时针转动调整螺丝⑦时,底线绕线量会增加,

相反则减少。

(3)顺时针转动螺母⑧时,梭芯绕的底线张力会增加

,相反则减小。

A. Winding lower thread

(1) Pass the thread thru the hole ① from the rear to the frontal

side of the tension adjusting dish②

(2) Bring the thread to the bobbin③ and wind it clockwise 5 t0 6

times from the bottom.

(3) Push the lever④ so that the pulley⑤ touches the V-belt and

run the machine.

(4) The pulley⑤ automatically is separated from the V-belt

when the lower thread is winded in the bobbin.

(5) The adequate amount of the pulled-out lower thread is

about 80%.

B. Adjustment of winding lower thread

(1) In case that the lower thread is winded irregular, loosen the

bolt ⑥ and adjust by moving it sideways, and tight it again.

(2) The amount of winded lower thread becomes larger when

you turn adjusting screw⑦ clockwise, and it becomes smaller

in case of turning it counterclockwise.

(3) The tension of lower thread that winded in the bobbin can

be adjusted by turning the nut⑧ : it increases with clockwise

turning and it decreases when you turn counterclockwise.

①

②

⑦

⑤

⑥

③

⑧

④

使用说明书 Operation Instruction

3

Loading...

Loading...