使用说明书 Operation Instruction

12

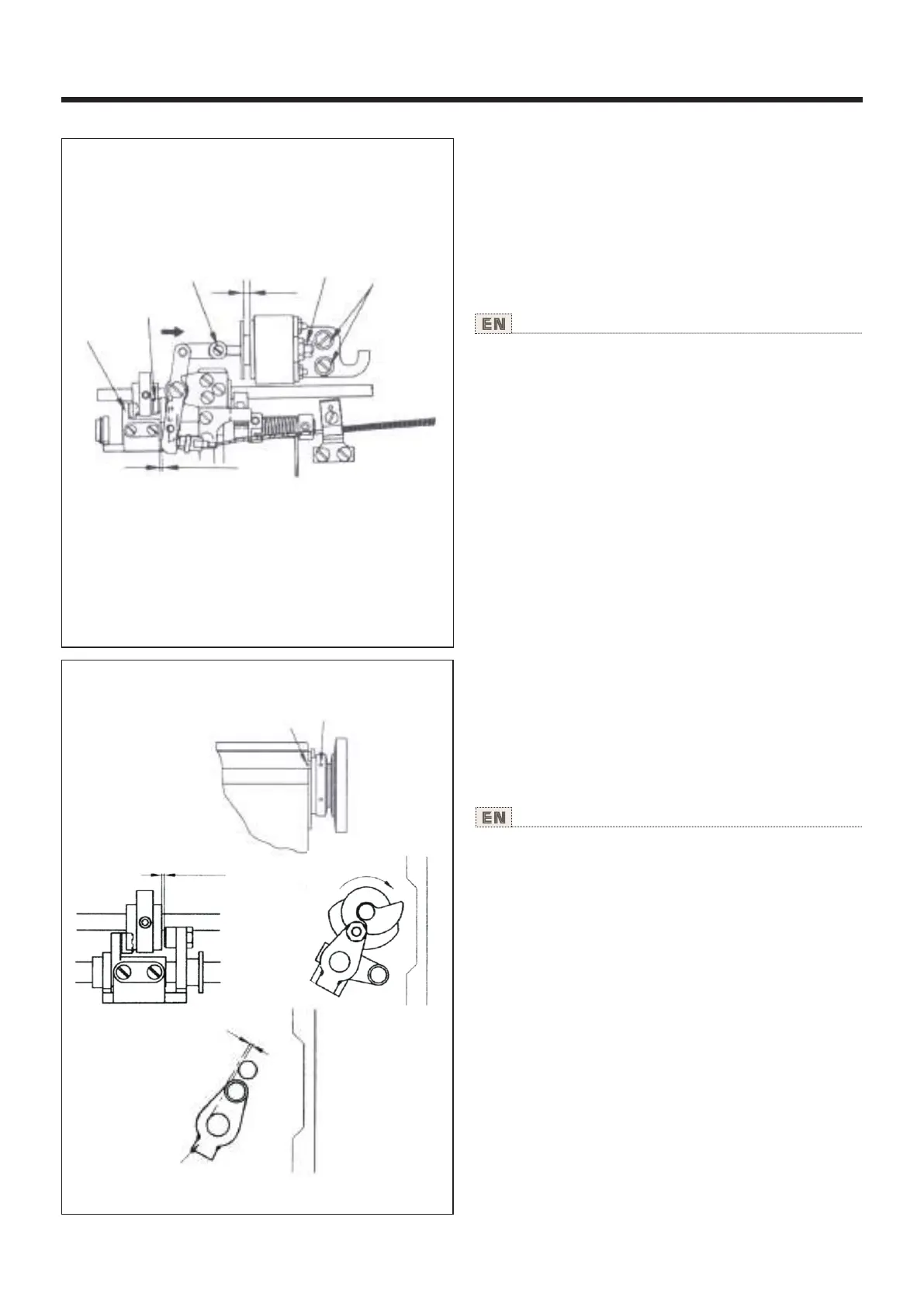

5、安装剪线凸轮

(1)将主动轮上的第2标记点对准机壳上的定位标记

点。

(2)在启动剪线电磁铁状态下,朝正方向回转剪线凸

轮①直到接触滚柱,然后固定凸轮。

(3)剪线电磁铁关闭,使凸轮曲柄②恢复到原始置,

这样凸轮与滚柱端面将以0.5-1.0mm间隙为标准。

标记 point

A

0.5-1.0mm

5 thread trimming cam

(1) Align the second timing carved line of the pulley with

the arm' s carved line.

(2) Under the thread trimming solenoid is in operation,

rotate the trimming cam ① clockwise and fix the cam when

it connected with the roller.

(3) When the thread cam following crank returned by

stopping the operation of the thread trimming solenoid,

the edge end between the cam and the roller should be

from 0.5 to 1.0mm. It is the standard.

.Installation of

①

0.6mm

②

20.剪线机构 的调整 Adjusting for thread trimmer(自动剪线型)

0.05mm

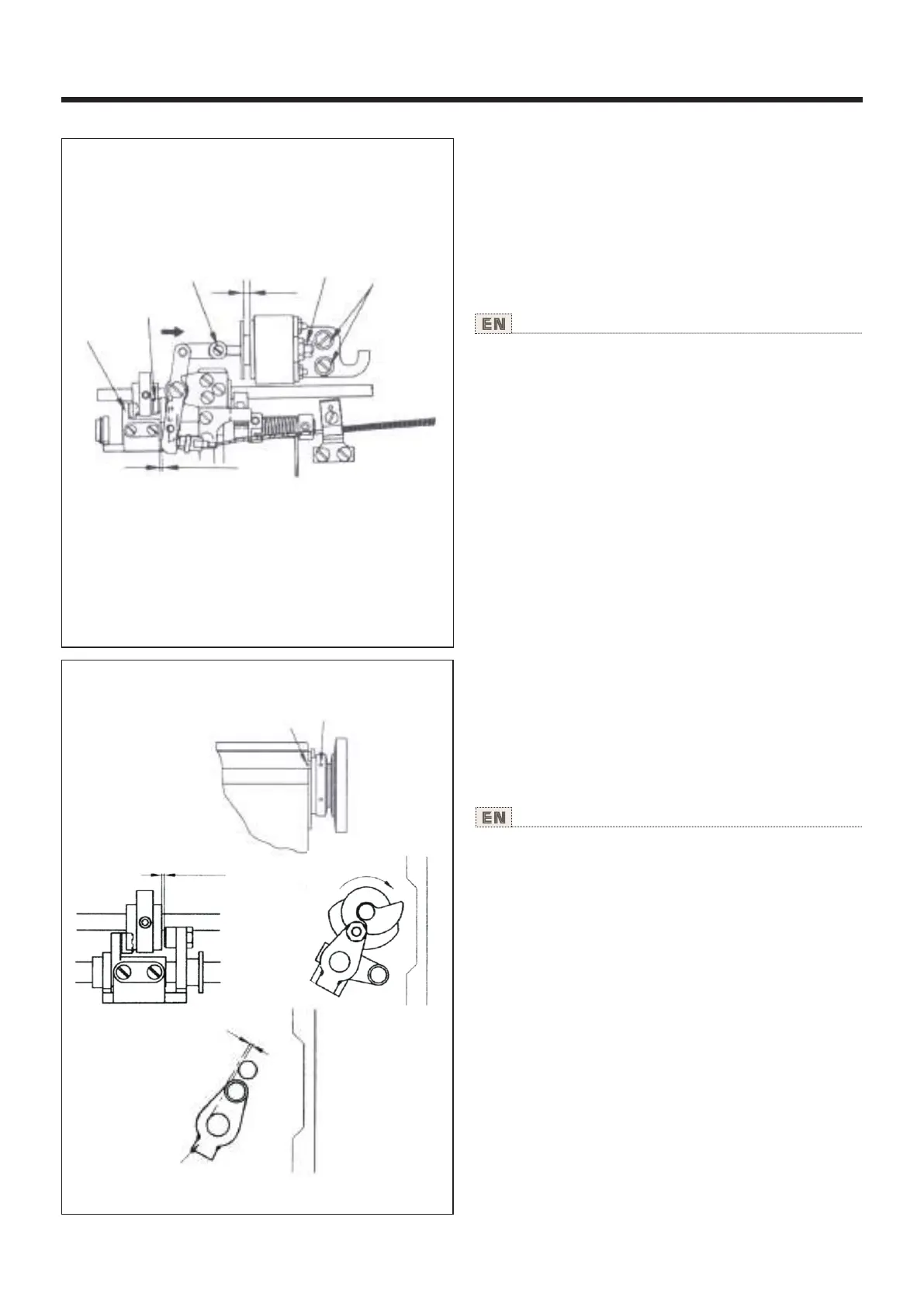

4.安装剪线电磁铁

(1)剪线电磁铁的行程:

A.标准的行程为4.6mm.

B.通过调节螺母A来调整行程。

(2)剪线电磁铁的调整

A.电磁铁的安装位置以电磁铁工作时,凸轮左曲柄

③与凸轮右曲柄②之间有0.5mm间隙为标准。

B.如需调整,可按图所示箭头方向移动电磁铁安装

架。

4.6mm

螺母A

nut A

电磁铁安装

架螺钉

electromagnet

mounts screw

电磁铁链接件

固定螺钉

e

fixed screw

lectromagnet link a

③

②

4.installation of thread trimmer

(1)working amount of the thread trimming solenoid.

A.The standard working amount of the thread trimming

solenoid is 4.6mm.

B.By adjusting the nut to adjust A trip.

(2)adjusting the thread trimming solenoid

A.if you run the solenoid under this circumstance,a gap of

0.5mm occurs between the left crenk ③ and the right crank

②.This state is the standard.

B.If you need to adjust.Can be shown as shown in figure and

direction of arrow mobile electromagnet mounts.

0.5 mm

Loading...

Loading...