Edificio Genebre. Av. de Joan Carles I, 46-48

08908 L'Hospitalet de Llobregat. Barcelona (Spain)

genebre@genebre.es - www.genebre.es

7e. Double check the correct assembly of the actuator, confirming that the open position

pistons are of equal distance from the cylinder border.

8. End cap mounting:

8a. Insert the end cap O-Rings (ref. 23) into their grooves by following the shape of the grooves

with a finger to ensure that the O-Rings are properly seated.

8b. Insert the stop bolt, nut and o’ring (ref. 18, 19, & 20) on tha lateral of body (ref. 4).

8c. Insert the indicator (ref. 2 & 3) and the seeger (ref. 1) on the pinion.

8d. Insert the end cap (ref. 25) on the body and tighten the screw (ref. 26) in an alternating order.

9. Adjustment:

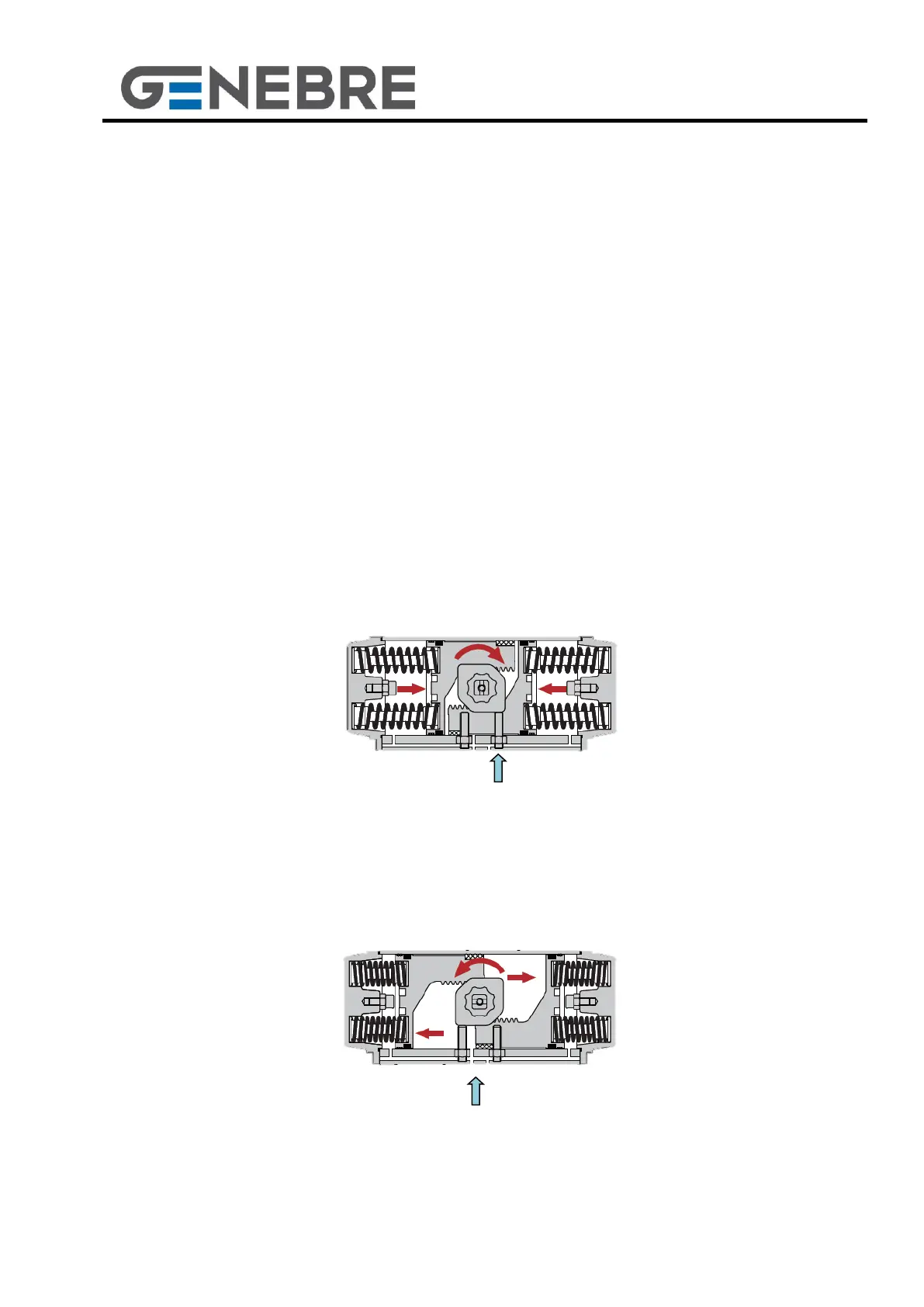

• Supply low pressure compressed air to Port B (see drawings). Using a

hex key wrench, turn the regulation screw (right) until the pinion shaft is

perpendicular to the actuator axis (0° position); tighten the nut.

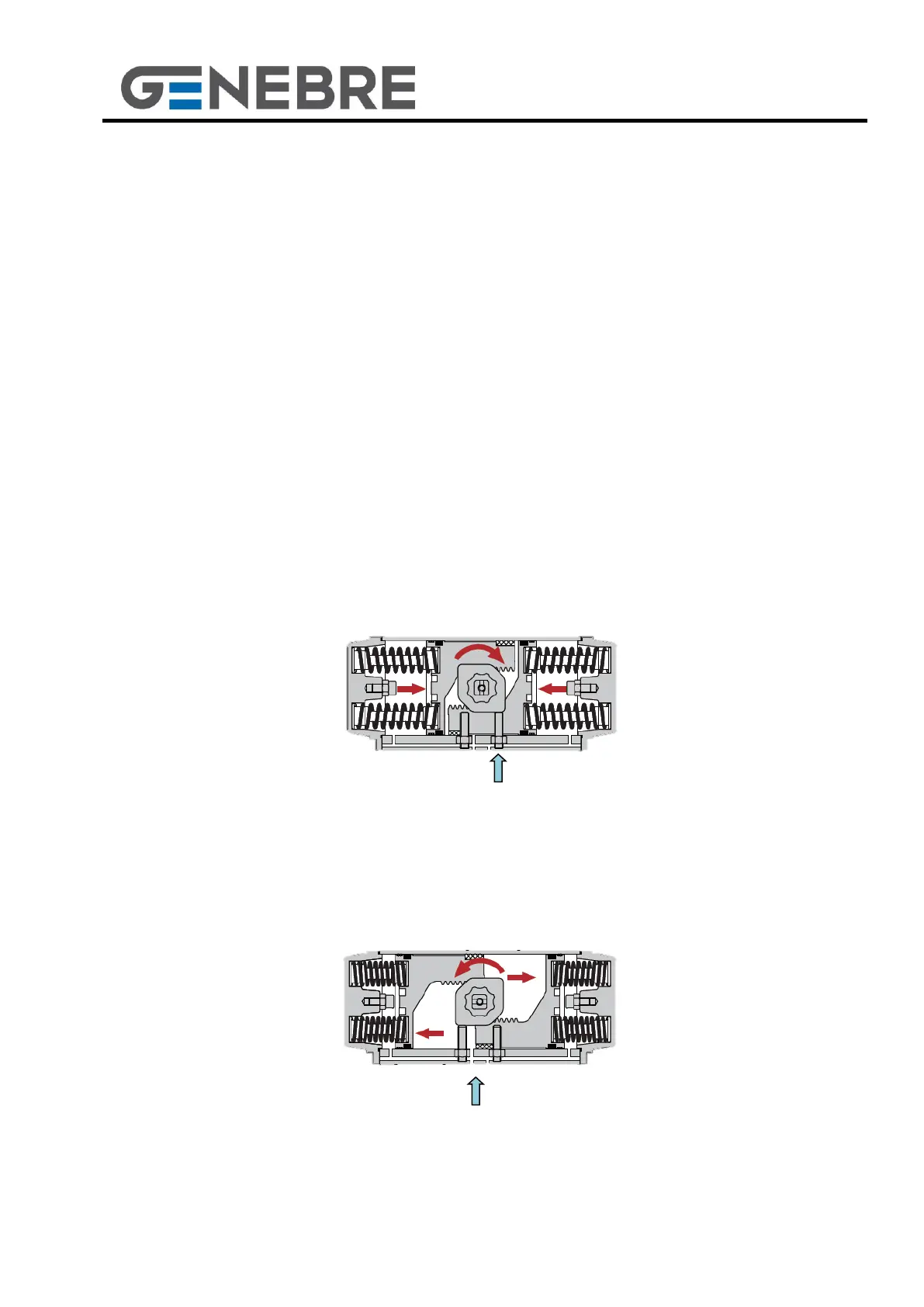

• Next, supply low pressure compressed air to Port A to open the actuator. The pinion

shaft must be at a 90° position (with respect to the 0° position), aligned with the

actuator axis. If it is not aligned, act on the stop bolt (left) and tighten the nut.

Loading...

Loading...