3-4

SECTION 3: CARBURETION AND FUEL SYSTEM

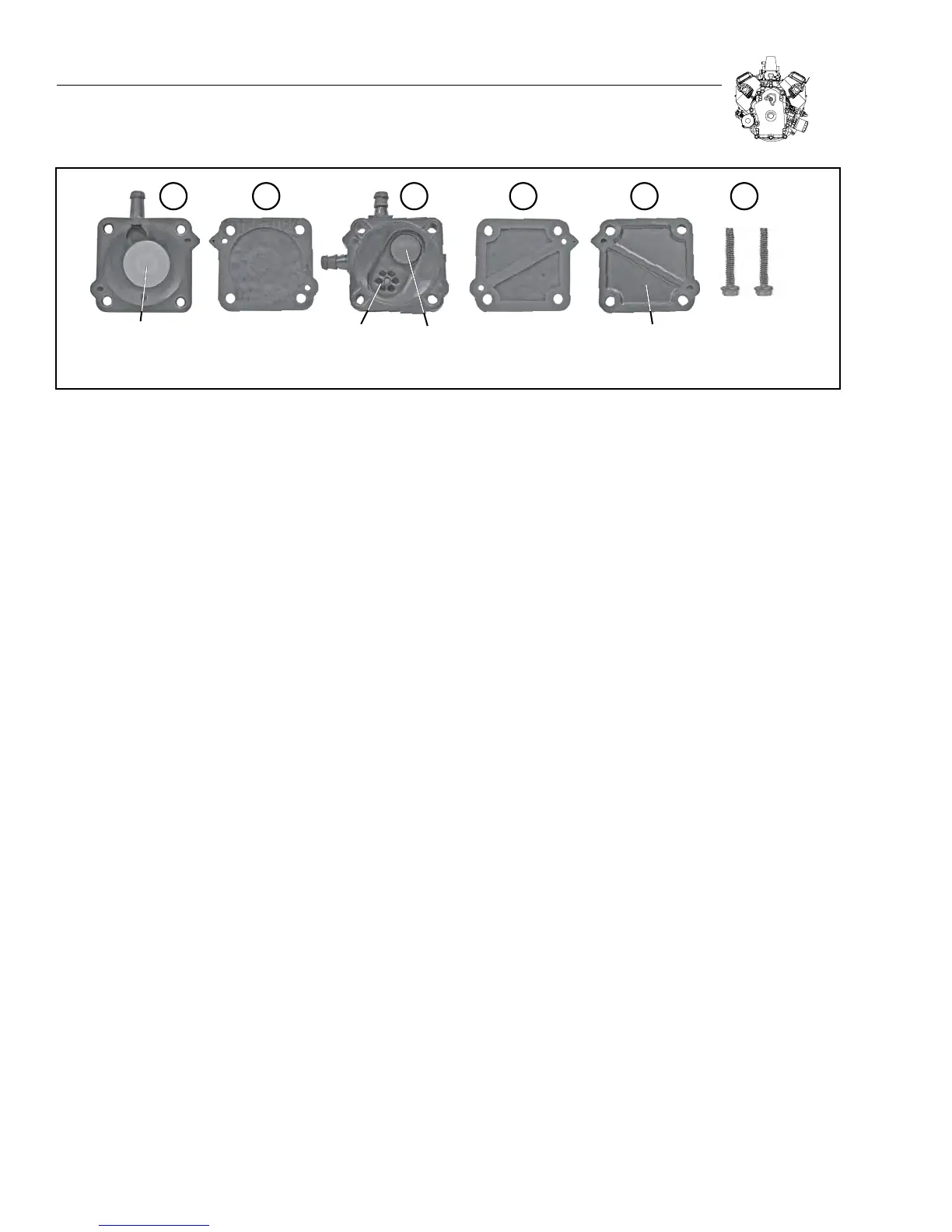

Fuel Pump Breakdown (see Figure 3-10):

1. Lower Spring Assembly

2. Lower Diaphragm

3. Check Valve Assembly

4. Upper Diagram

5. Upper Vent Assembly

6. Mounting Hardware x 2

As crankcase vacuum is built up the Lower Diaphragm pulls down

against the Spring Return and allows fuel to flow through Check-Valve

2. As pressure builds up in the crankcase, the Spring Return pushes

up against the Lower diaphragm, allowing fuel will flow through Check-

Valve 1 and out the fuel port.

LP (LIQUID) - FUEL SYSTEM

*

Proper service and repair is important to the safe and reli-

able operation of all gaseous fueled engines. Any servicing

or testing of a gaseous fueled engine must only be performed

by qualified personnel. Always follow applicable installation

and service procedures. An example of these requirements

is found in NFPA-58 for liquid propane. These are US Federal

standards. Worldwide standards vary. Local, city, and state

requirements may also have certain requirements that must

be observed.

LP (Liquefied Petroleum Gas) is a gaseous fuel and when stored under

pressure, becomes a liquid. Although a vapor forms at the top of the

tank, this particular system uses a liquid withdrawal method, drawing

liquid from the bottom of the tank.

This is accomplished with a special valve that is installed on a normal

propane cylinder with a tube that is attached to the valve and extends

to the bottom of the storage tank. Pressure in the tank forces liquid

propane through the tube when the valve is opened.

The Generac LP system starts with a pressure relief valve to prevent

excessive pressure from building in the system during shutdown.

This is followed by a 12 volt (normally closed) electric solenoid,

which prevents the flow of fuel when the ignition key is off. When the

ignition key is turned on, the solenoid opens and allows liquid LP to

flow to the regulator.

The liquid fuel vaporizer/regulator converts liquid propane to vapor.

The vaporizer/regulator uses either spent engine cooling or engine oil to

provide heat to aid in the evaporation process. The vaporizer/regulator

controls the vapor supply to an amount required by the engine. The

engine’s intake vacuum draws LP into the fuel mixer on an on-demand

need. When the engine is off, LP no longer flows from the vaporizer/

regulator to the engine (see Figure 3-32).

TROUBLE SHOOTING

*

CAUTION! Gaseous fuels are highly explosive; do not use flame

or heat to test the fuel system for leaks. LP gas is heavier than

air and tends to settle in low areas; even the slightest spark

can ignite these gases and cause an explosion.

Note: Don’t assume that the fuel system is the problem. Verify that

the engine has spark and enough compression to start the engine

before proceeding with the following steps.

SPRING

RETURN

1 2 3 4 5 6

LOWER

DIAPHRAGM

UPPER

DIAPHRAGM

VENT: UPPER

VENT ASSEMBLY

FUEL

CHECK-

VALVE 1

FUEL

CHECK-

VALVE 2

HARDWARE

Figure 3-10. Fuel Pump Assembly

Loading...

Loading...