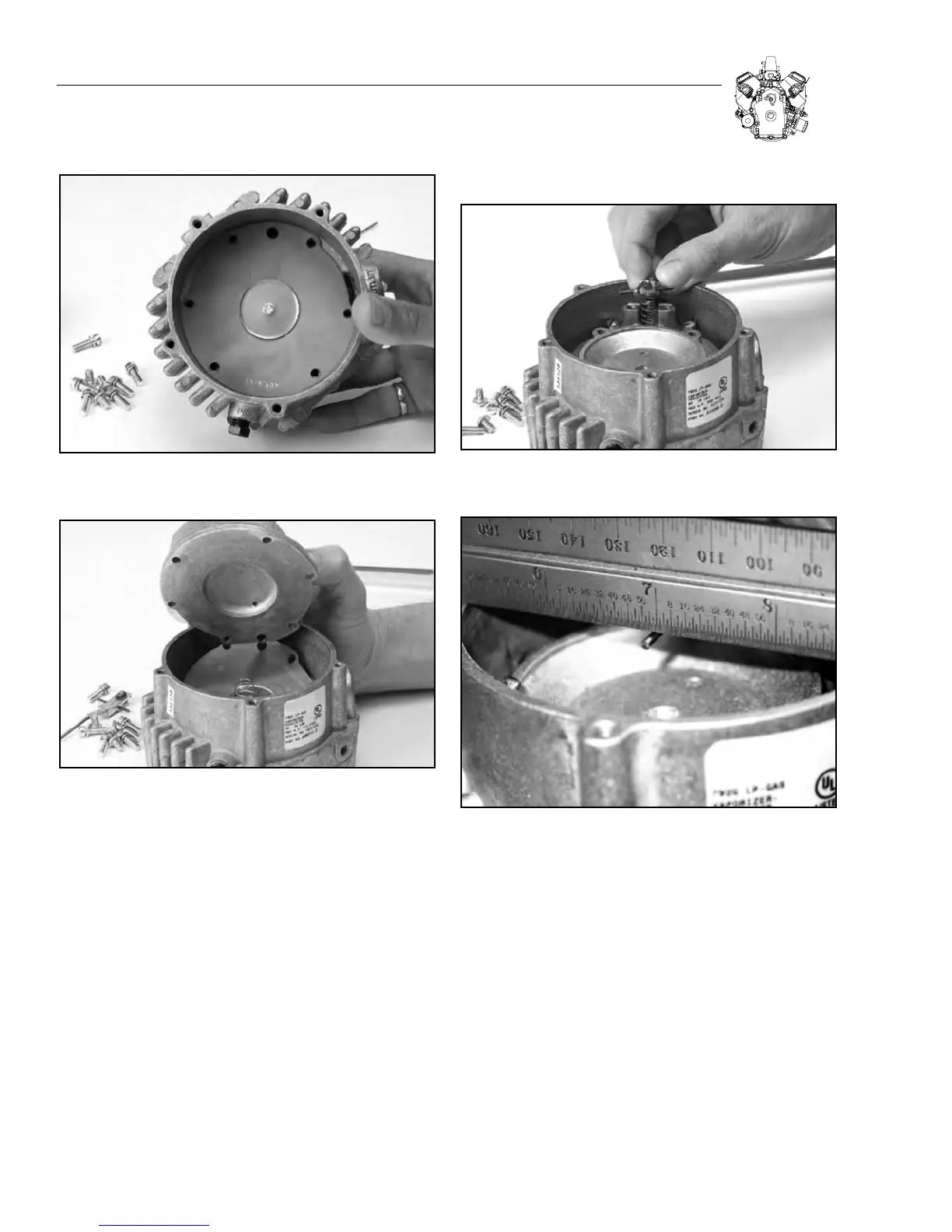

Figure 3-19. Rotate The Diaphragm To Align the

Cover Screw Holes

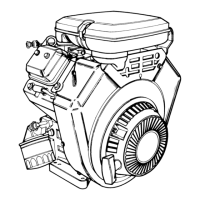

Figure 3-20. Install Primary Spring, Primary Cover and Screws

9. Place secondary valve spring (5/16” dia. x 5/8’ long) in spring

recess near secondary orifice. Replace secondary lever, pivot

pin, 1.19” long, and two screws, 10-32 x 0.310”. Make sure the

spring fits over the spring boss on the secondary lever. Tighten

screws evenly to 30 in. lbs. ±3 in. lbs. (3.39 Nm ± 0.339 Nm).

See Figure 3-21.

10. The secondary lever (except for the bent tail tip) should be level

or flush with the top of casting. Bend tail end of lever if necessary

but do not use excessive force on the rubber valve against the

orifice. See Figure 3-22.

11. The secondary lever has a soft valve surface on an aluminum

insert which must be swiveled into flat contact with the orifice.

Place a pointed instrument in the top indentation of the valve. Apply

slight downward pressure and with a gentle rotary motion, swivel

the valve into flat contact with the orifice. These valve inserts are

not sold separately but are crimped at the factory with proper

tension to allow movement but still hold their position. See Figure

3-23.

Figure 3-21. Install Secondary Valve Spring,

Lever and Pivot Pin

Figure 3-22. Make Sure Secondary Lever is Flush

With Top of Casting

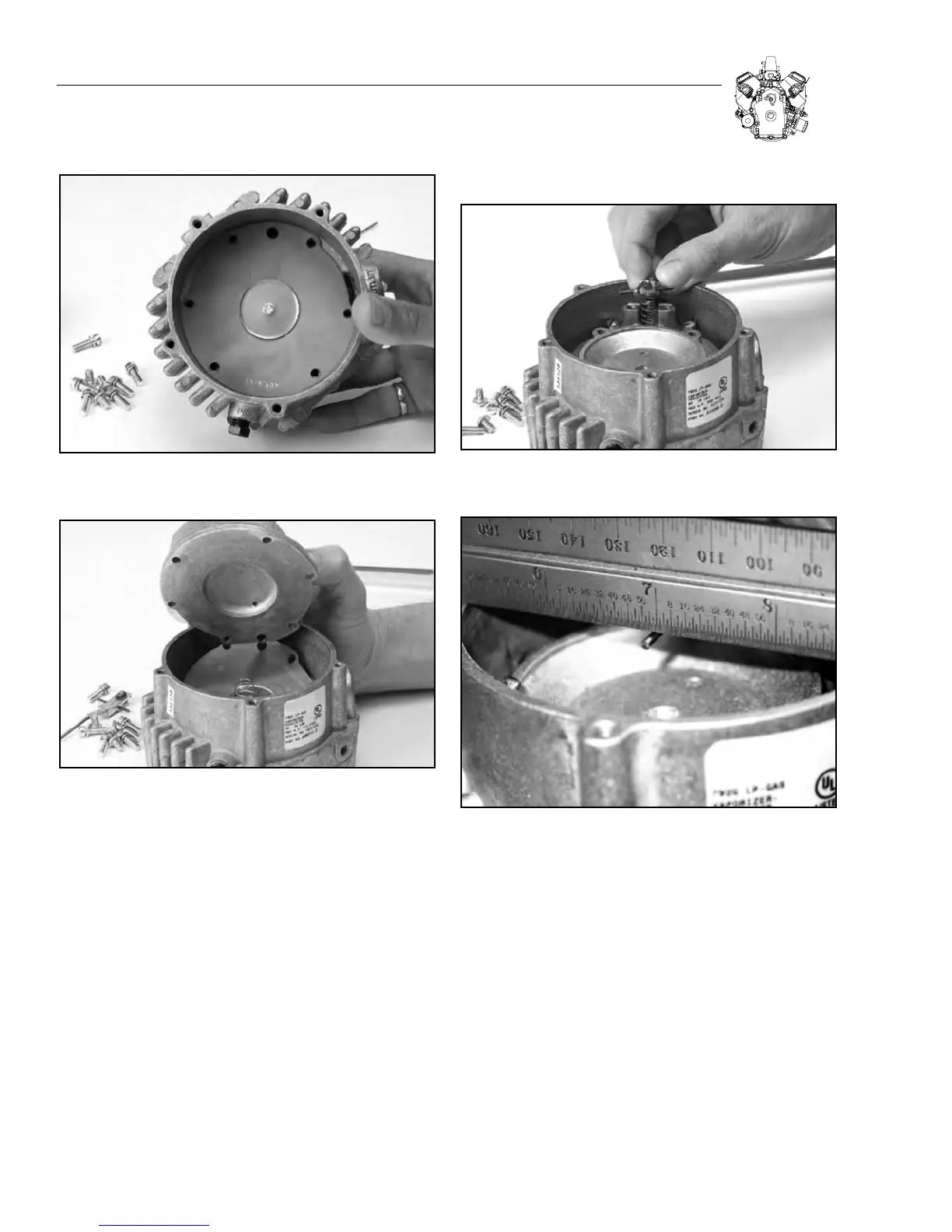

12. Attach primary pressure gauge at the primary pressure test port

opening. See Figure 3-24.

13. Attach air pressure hose to the regulator fuel inlet with

approximately 100 psi, ±10 psi air pressure. See Figure

3-25.

14. Slowly depress the secondary lever bent tail end until you are

able to detect flow out of the secondary orifice. Let the lever then

slowly return to the closed position. Observe the primary pressure

reading on the installed gauge. It should be between 0.8 and 2.5

psi. If it is not, recheck your work in the primary fuel section. See

Figure 3-26.

3-8

SECTION 3: CARBURETION AND FUEL SYSTEM

Loading...

Loading...