SECTION 2: IGNITION

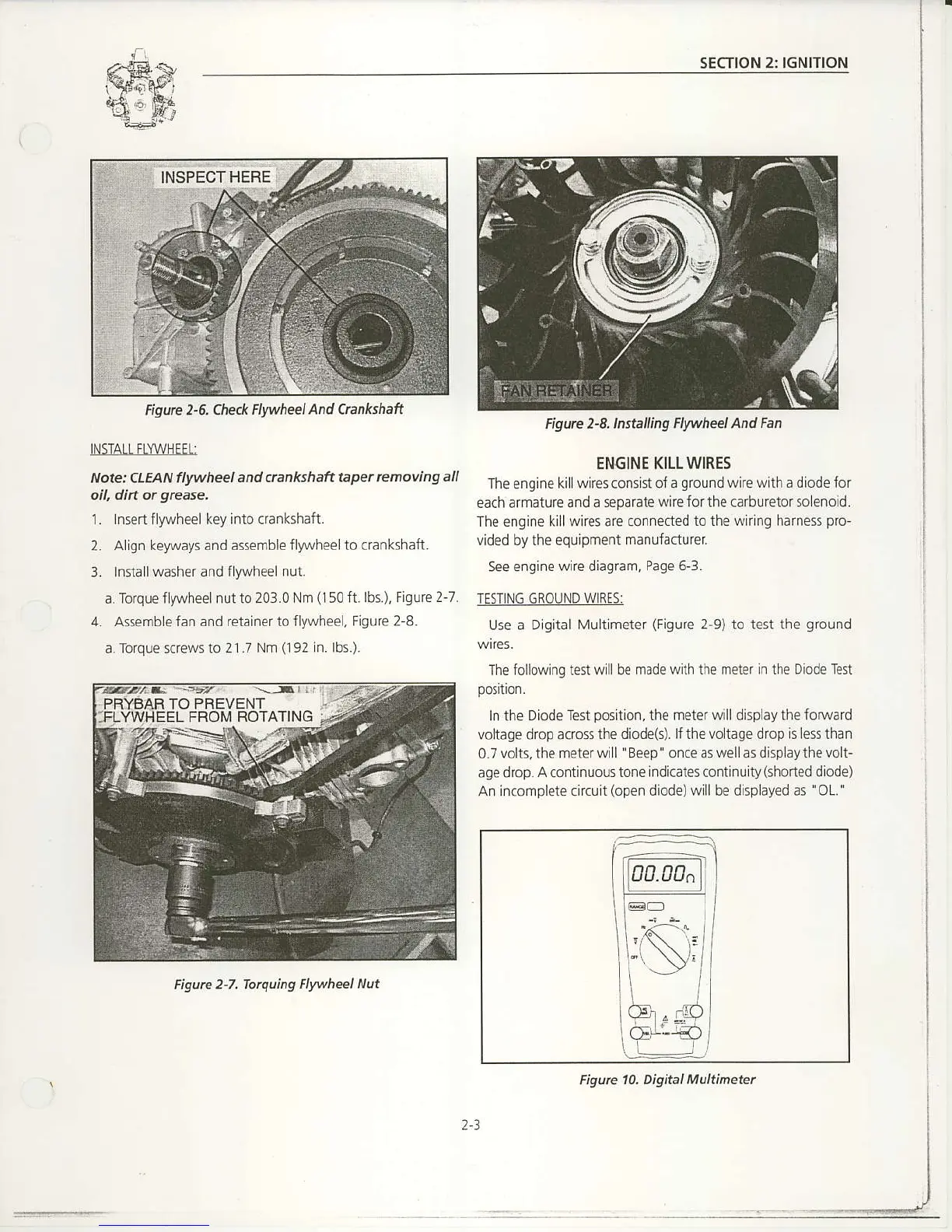

Figue 2-6, Che.k

Hwheel And eankshaft

INSTALL FL\ryVHEEL:

Note: CLEAN flwheel

and

(ankshaft

taper removing

all

oil, dirt or

gtease.

1.

Insertflylvheel key into crankshaft.

2. Align

keyways and assernble flylvheel to crankshaft.

3. Installwasher and

flylvheel nut.

a. Toque fly,vl/heelnut to

203.0 Nm

(150

ft.lbs.),

Fiqure 2-7.

4. as5emblefan and retainerto

flywheel, Figure 2 8.

a.Torque screws to

2l.7 Nm

(192ln.

lbs.).

Figure 2-7,

Totquing Flwheel Nut

Figurc 2-S.lnsta ing Flywheel And

Fan

ENGINE KILL WIRES

The

engine

kill wires conslst of a

grcund

wire with a diodefor

each armatureand

a separate wire for the carbu retor solenoLd.

The engine killwires are connected

to the wirlng harness

pro-

vided by the equipment manulacturer

See engine

wire diagram,

Page 6-3.

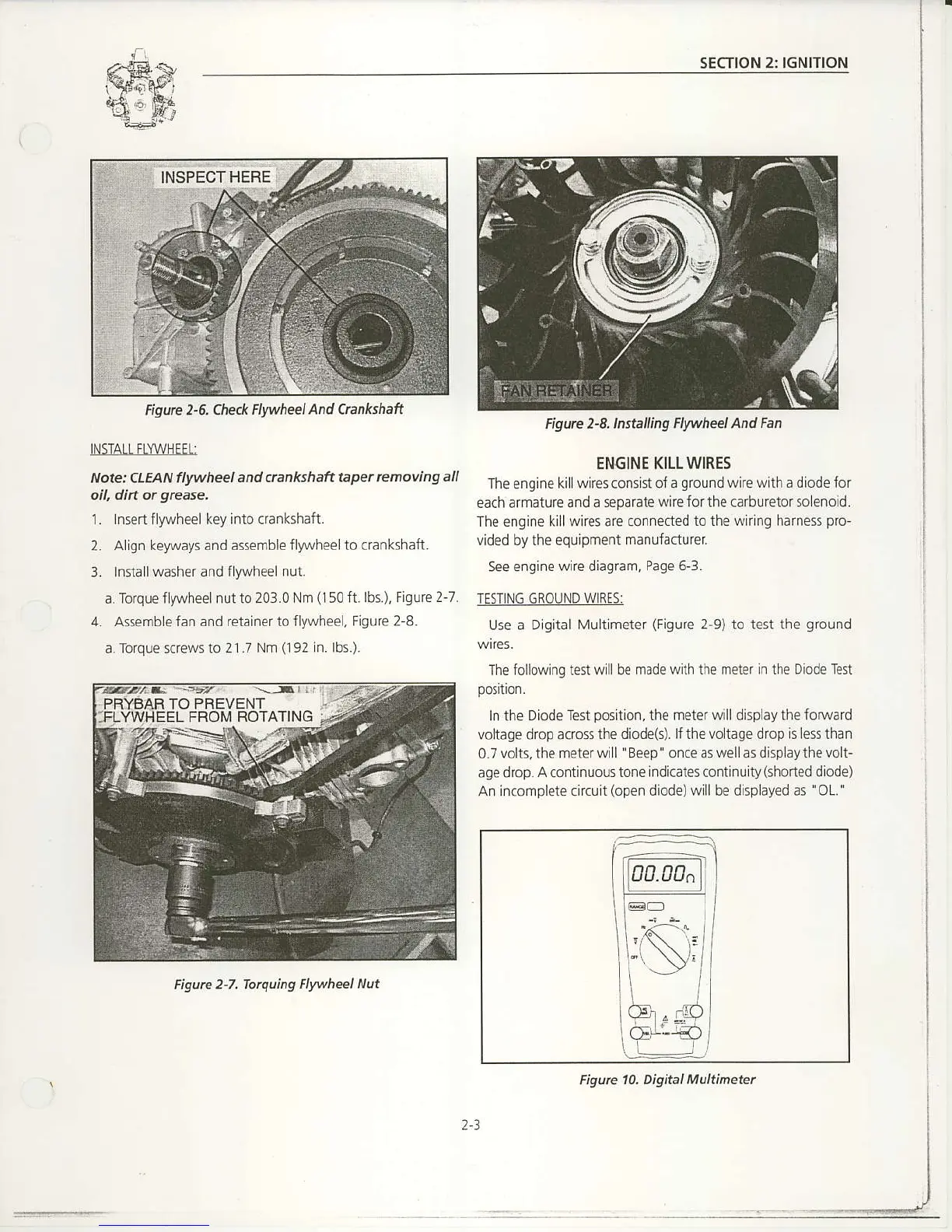

TESTiNG GROUND WIRES:

Use a

Digital Multimeter

(Figure

2-9) to test the

ground

wires.

The iollowing test w

llbe made with the meter in the Diode Ten

In the Diode

Test

position,

the meter will display the foftvard

voltage drop acrcssthe

diode(s). lf the voltage drop is less than

0.7

volts, the meter will

'

Beep' once as

well

as display the

volt-

age drop.

A

continuous

tone indicates continuity(shoned diode)

An incomplete circuit

(open

diode) will be displayed as

'OL. '

2.3

Figurc 10. Digital Multinetel

Loading...

Loading...