SECTION

13: ENGINE ASSEMBLY

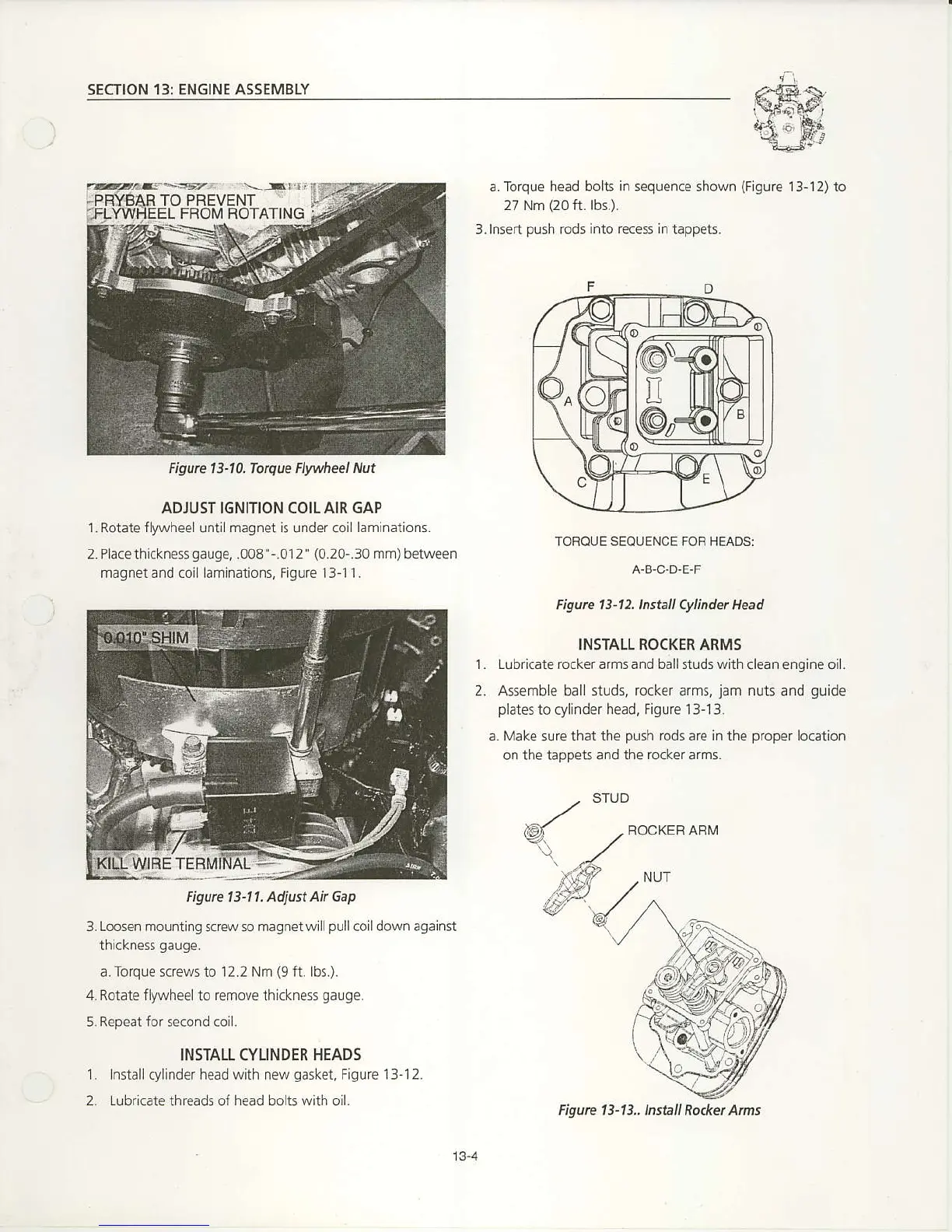

a. Torque head bolts

in

sequence shown

(Figure

13-12) to

27 Nm

(20

ft. lbs.).

3.lnsen

push

rods into

recess

in tappets.

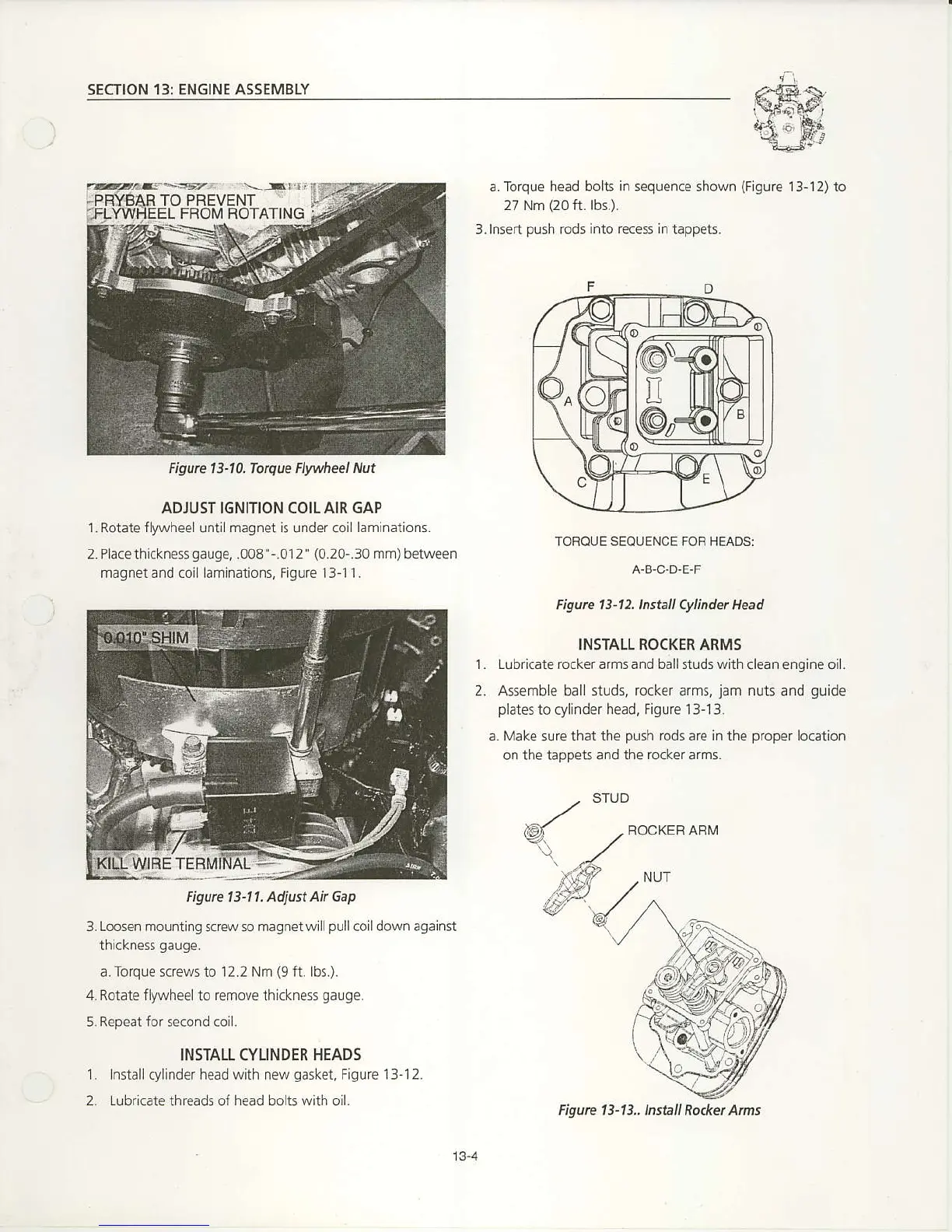

ADJUST IGNITION COILAIR 6AP

'LRotate

flylvheel until magnet is under coi

laminations.

2.Placethickness9au9e,.008"-.012'

{0.20-.30

mm)

between

magnet and coil laminations, Fig ure l 3- 1

.I

.

TORQUE SEOUENCE FOR HEADS:

A.B,C,D.E.F

Figwe 13'12lnsli Cylinder Head

INSTALL ROCKER ARMS

1. Lu bricate rocker arms and ballstuds with

clean engine oil.

2, Assemble ball studs, rccker arms,

jam

nuts and

guide

plates

to cylinder head,

Figu€ 13-l3.

a.

Make

surc that

the

push

rods are in the

proper

location

on the tappeti and the

rocker

arms.

3. Loosen mounting

screw so

magnet will

pull

coil down against

thickness

gauge.

a. Torque screws to l2-2 Nm

(9

ft. lbs.).

4. Rotate fll1,1/heelto

emove thickness

gauge.

5,Repeat for second coil.

INSTATI. CYLINDER HEADS

1. Installcylinder head with new

gasket,

Figure 13-12.

2.

Lubricate

threads of

head

bolts

with

oil.

FOCKER ARM

Figwe 13-10. Torque Flwheel

Nut

@".fr

nilil

@r,<

\

/B

Figute 13-11. Adjust

Ak Gap

13-4

Figute 13-13.,lnstall Rod<et Ant

Loading...

Loading...