SECTION 13: ENGINE

ASSEMBLY

SECTION CONTENTS

lNsTALL CRANKSHAFr ............__........................_.........

13-1

|NSTALL PISTON AND CONNECTTNG

ROD .................... 13-1

tNsTALL CAMSHAFL............_....._...................____.........

t3-2

tNSTALL CRANKCASE COVER .._.......................__..........

13-2

GENERALASSEtV8LY.................__.................................

t3-3

tNsTA11 8REATHER ......................................................

13-3

|N5TALLFL\1|/HEEL.......................

............13-3

ADJUST tGNtTtON COtL AtR GAP..................................

13-4

tNSTALL CYLTNDER HEADS ............................................

13,

ADJU5TVA1VE5............................._..............................

13-

INSTALL CRANKSHAFT

Lubricatemagbearingandlipsof

oilsealwithengineoiland

installcrankshaft.

Figure 13-1.

Insta ing Qankhaft

INsTATL

PISTON AND CONNECrING ROD

Note: lnstall

*t

pinon

and connecting rcd tiEL

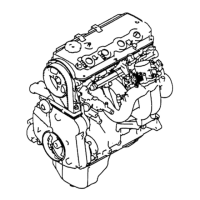

1 - Oil

piston

ngs,

piston

skift, and compress rings with Ring

Comprcssor, Figure

l3-2.

a.

Place

piston

and ring compressor upside down

on bench

with

projedions

on comprcssor facing

up.

b.Tlghten ring

compressor evenly until rings are fully

com-

pressed.

c. Then loosen ring compressor very

slightly so th:t com

pressor

can be

rotated

on

piston

skirt while holding

connecting rcd, Figure 13-2.

d, Remove connecting rod cap.

Figure 13-2. Conpresting Rings

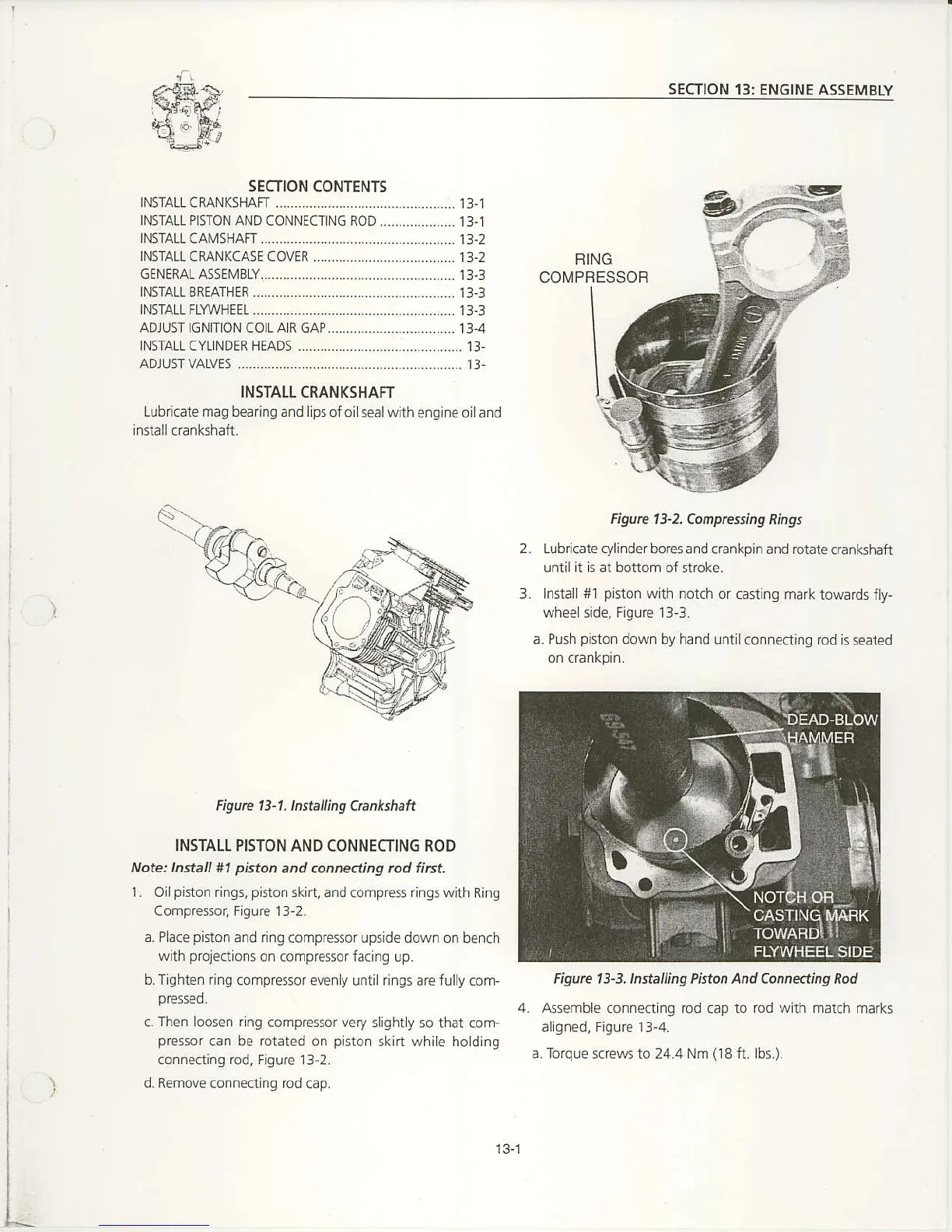

2. Lub cate cylinder borcs and crankpin and rotate

crankhaft

until it is at bottom of stroke.

3. Install #l

piston

with notch or

casting mark towards fty-

wheelside, Figurc 13-3.

a.

Push

piston

down

by hand untilconnecting rod

is seated

4. Assemble

connecting rod cap to

rod with

match marks

allgned, Figure 13-4.

a. Torque screws to 24.4 Nm

(18

ft. lbs.).

FIING

COMPFESSOB

Figure 13-3, lnsElling Piston And Conneding Rod

13-1

Loading...

Loading...