Mini-Rooter XP™

5

Operation

1. Begin by pulling the cable from the drum and sliding it into the

drain as far as it will go.

2. Tighten the knob at the top of the Power Cable Feed so that the

feed roller presses against the cable. Be sure not to over tighten

since this could cause excess cable wear. Note: The Power Ca-

ble Feed is designed for use with 3/8‖ and 1/2‖ cables only.

3. The feed lever controls the feeding rate and direction of the ca-

ble. Move the lever down to feed the cable out of the drum. The

further the lever is moved downward, the faster the cable will

feed out. Move the lever up to retract the cable into the drum.

When the lever is in the middle (neutral) position, the cable will

spin in place.

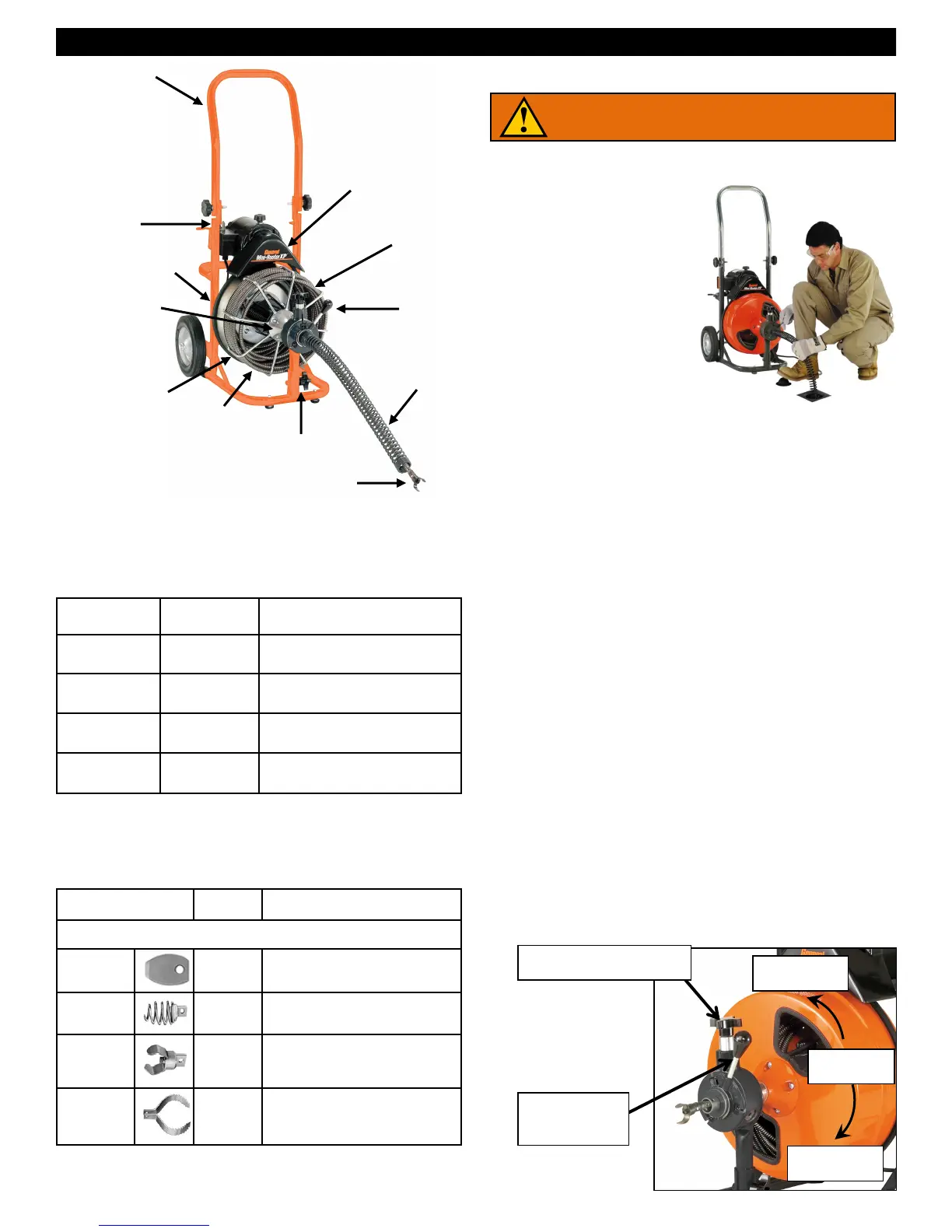

Feed Control

Lever

Feed Pressure Knob

Reverse

Neutral

Forward

Cable Application Chart (Table 1)

Cable Size Pipe Size Typical Applications

1/2" 3" to 4"

Roof Stacks and Small Floor

Drains (No roots)

3/8" 2" to 3"

Roof Stacks, Laundry Lines and

Small Drains

*5/16" 1-1/2" to 2" Sinks, Basins and Small Drains

*1/4" 1-1/4" to 2"

Small Lines, Tubs and Shower

Drains

*The 1/4‖ and 5/16‖ diameter cables are for use with the J-Drum and

Dual Drum.

OPERATING INSTRUCTIONS

Set-Up

1. Place machine within ap-

proximately two feet (.6m) of

drain opening. Be sure the

Mini-Rooter XP Guide Tube

(XP-GT) is in place. If you

can’t place the machine this

close to the drain opening,

run the cable through the

optional Guide Tube Exten-

sion (GTE) or a metal guide

tube to prevent cable whip-

ping. On manual feed ma-

chines, always keep a gloved

hand on the cable.

2. Position the foot pedal for easy accessibility. The machine is

designed for one-person operation. Be sure you can quickly re-

move your foot from the pedal in an emergency.

3. Be sure the motor switch is in the off position.

4. Select the proper cutting tool (See Cutter Application Chart—

Table 2). A good tool to start with is the Arrow Head or Boring

Gimlet. After the line is opened, follow with larger blades, which

scrape the inside edges of the pipe, assuring a real cleaning job.

5. Insert the cutter into the female connector at the end of the 3/8"

or 1/2" cable and tighten the connecting screw and lock washer

firmly in place.

Cutter Application Chart (Table 2)

Cutter Cat. # Typical Applications

Cutters for 3/8” and 1/2”Cables

Arrow Head

AH

Starting tool, ideal for cutting and

scraping.

Boring

Gimlet

BG

Starting tool, to remove loose

objects.

1-1/2‖

U-Cutter

1-1/2UC

Finishing tool, works well in

grease stoppages.

2‖ Side

Cutter Blade

2SCB

Finishing tool, for scraping inside

edges of pipe.

Note: There are no fixed rules for what cutter to use. If one tool

doesn’t take care of a stoppage, simply try another.

NOTE: Do not operate machine if warning labels on the switch box

and power cord are missing or illegible.

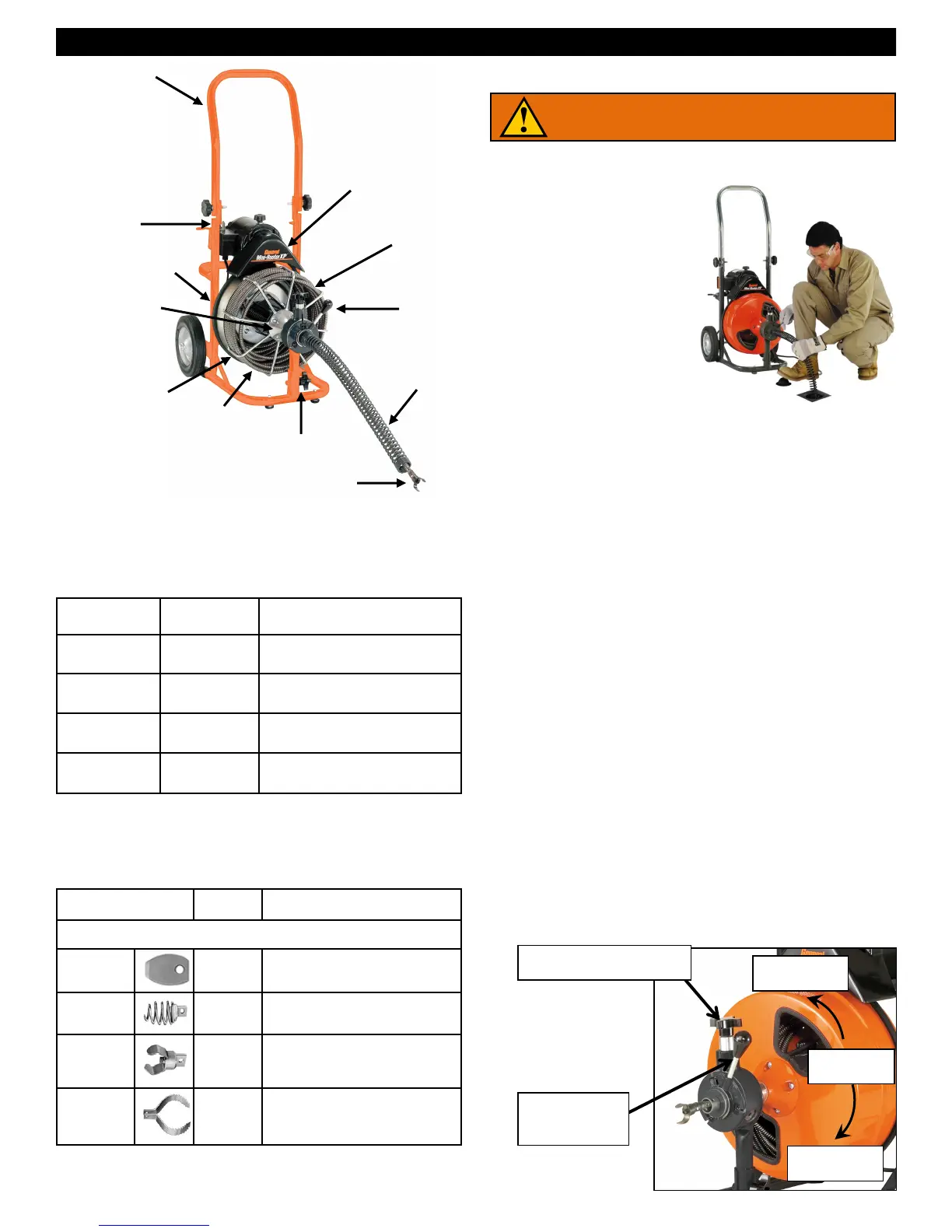

Folding Handle

Motor Switch

V-Belt

Front Drum Hub

Open Drum

Cable

Front Post Knob

Cutter

Guide Tube

Feed Control

Lever

Feed

Pressure

Knob

Belt Guard

MAKE SURE THE MOTOR SWITCH

IS IN THE „OFF‟ POSITION!

Loading...

Loading...