1-5

Introduction to GR228X Test Systems

A dedicated functional test system is often used for functional testing. Alternatively, you can move

many of the functional tests to the GR228X Test System which has many of the necessary hybrid

test capabilities built-in. The ICA systems contain instruments for testing groups of analog

components, groups of ICs using the system’s parallel Driver/Sensors, and groups of hybrid

components using the AWG, DMM, and ACM in addition to the other instruments. Functional testing

may require the addition of optional power supplies. The Hybrid Test Library (HTL) enables you to

develop a library of functional tests that can be automatically generated. Functional testing enables

you to collect additional test statistics using the system’s data logging feature.

In-circuit testing individually checks the performance of each component on the board with little or

no operator probing. Occasionally a fault such as an open connection needs to be localized further.

The GR228X systems offer a scratchprobing technique that can discriminate between a poor test

probe contact, a bent IC pin that was not inserted correctly, or a broken track.

Performing a combination of in-circuit and functional tests provides the most thorough fault

coverage. The GR228X software and hardware are optimized for in-circuit component testing,

therefore, the test development process focuses on in-circuit testing. GR228X systems can also

perform “clusters” of functional tests using the same test fixture. By grouping the UUT into

functional clusters, you can simplify test development and improve the diagnostic accuracy of

failing cluster tests.

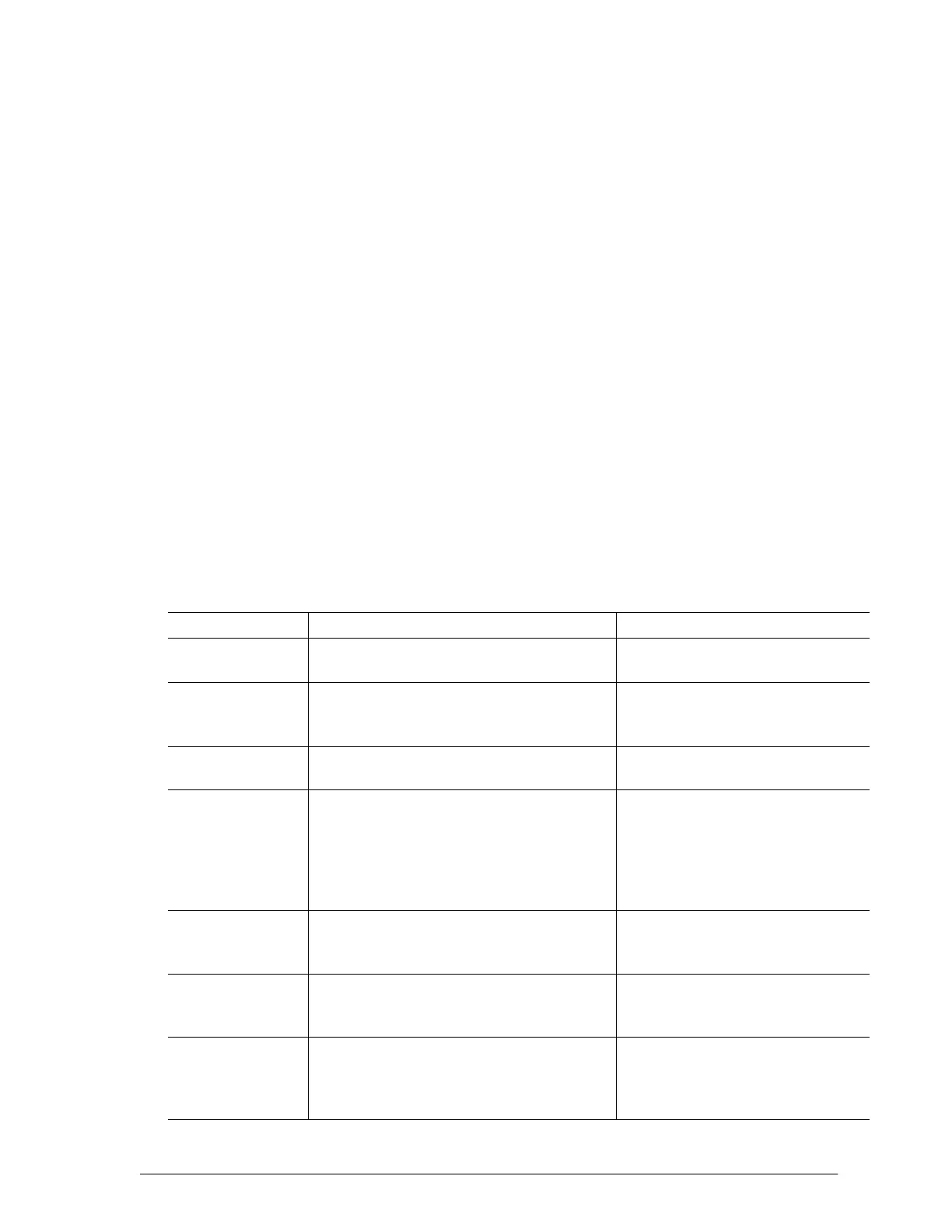

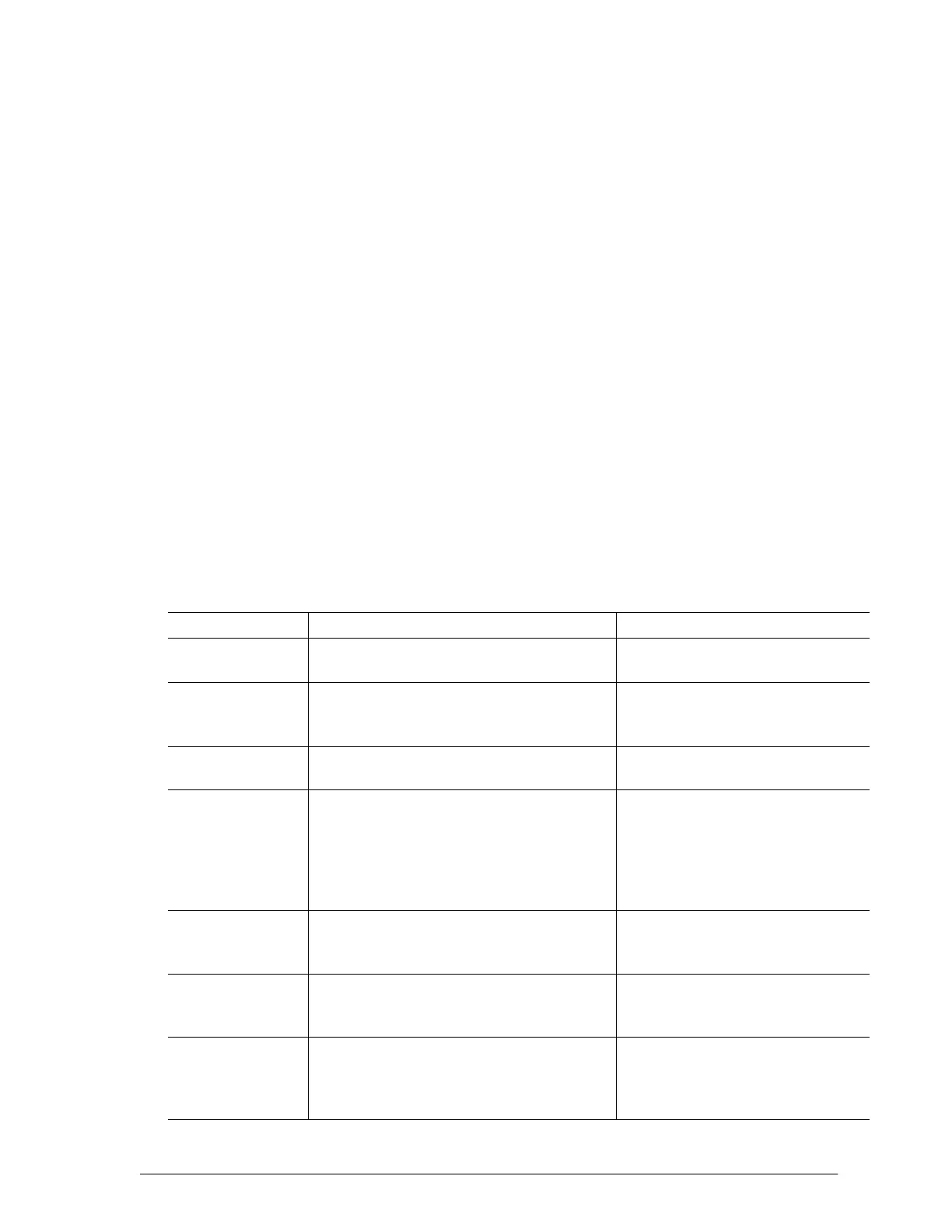

Table 1–2 identifies and contrasts the major characteristics of functional and in-circuit testing.

Table 1–2

Functional and In-Circuit Test Characteristics

Characteristic

Functional (Board-Edge) Test In-Circuit Test

What is tested Component inputs and outputs. Component connections, values,

and functions.

How is it tested Power is applied to the board. Component-by-component;

power is applied to UUT for digital

and hybrid tests.

Fixture

requirements

Board edge connector that may accept

many boards.

Bed-of-nails fixture for each

board design.

Software

requirements

Can use an optional circuit simulator as a

diagnostic aid to predict outputs and fault

coverage. Test development requires a

simulator library, and a programmer to

write part of the test. It requires a longer

test development cycle.

Automatic Test Generator (ATG)

writes the test using test libraries.

The hybrid library can generate

functional tests.

Component

library

Must contain complete transfer function or

truth table for each digital device.

Contains analog, digital, and

hybrid model tests, written for a

variety of circuit environments.

Fault diagnosis Provided by guided operator probing; fault

identification depends on adequate

simulation.

Probing is not required to obtain

good fault identification.

Fault coverage Excellent fault coverage, although both

the test development and debug time are

lengthy. Also, manufacturing faults may

not be detected.

Excellent fault coverage with fast

test development and debug

time.

Loading...

Loading...