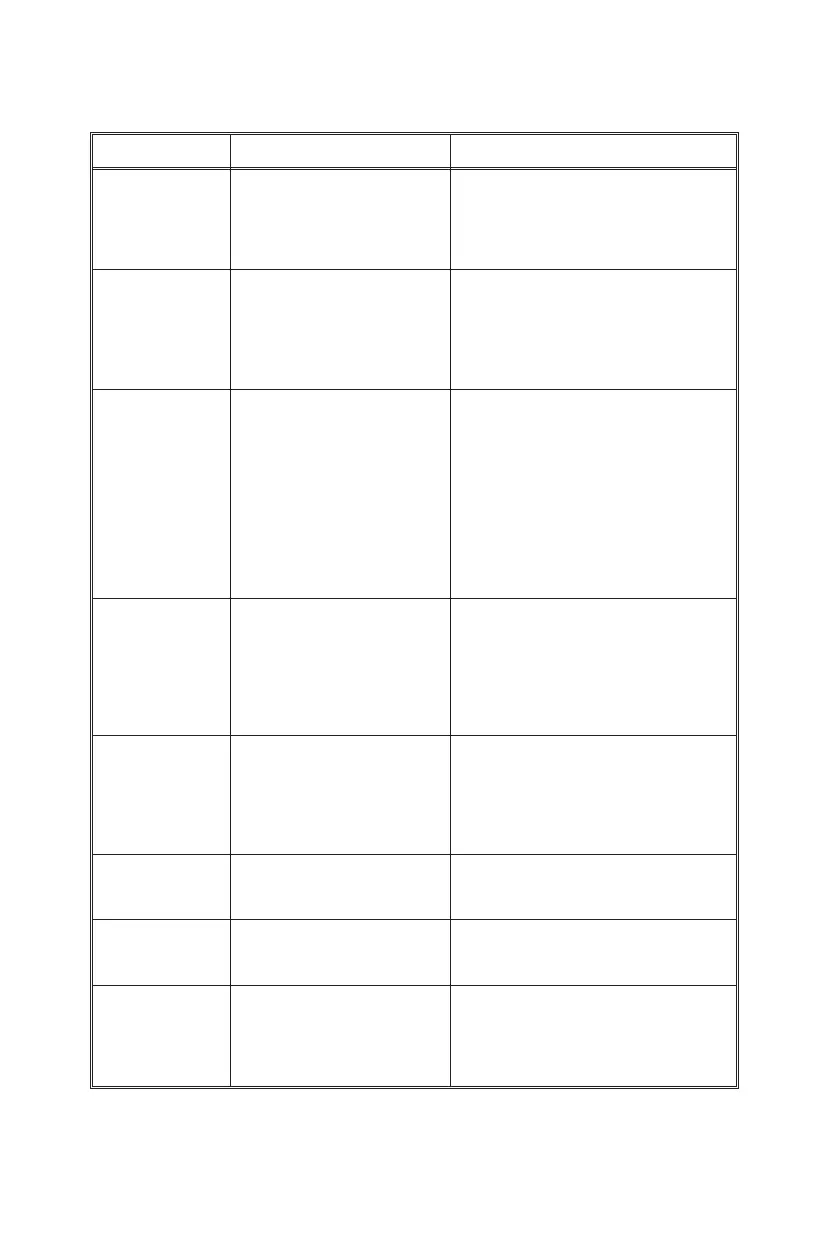

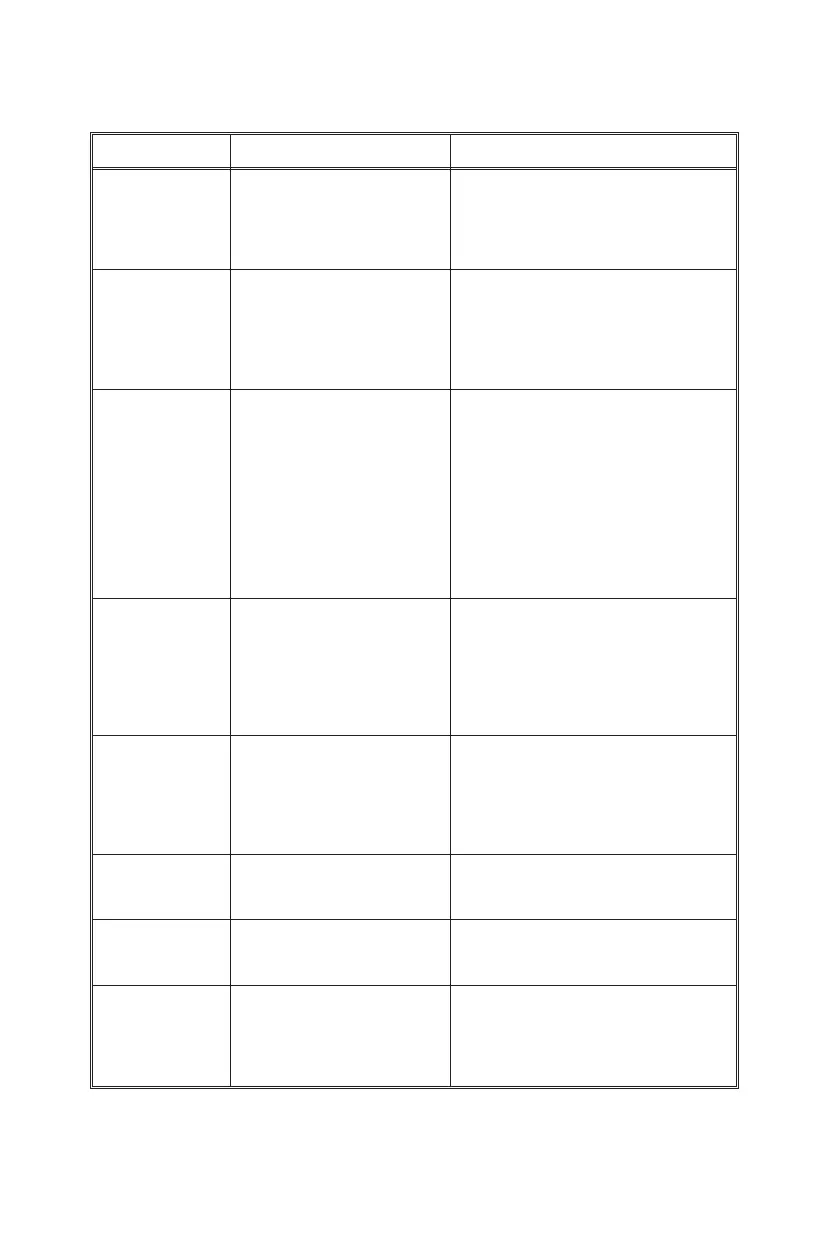

Table 1. Periodic Inspection

COMPONENT INSPECT FOR: APPLICABLE PROCEDURE

Helmet Shell Cracks, holes, warping.

Cleanliness.

Remove all components; install

components in replacement shell.

Clean per instructions on the next

page.

Energy-

Absorbing

Liner

Worn or loose hook

fasteners.

Gouges, cracks,

indentations.

Remove liner as in Replacement

Procedure 1, Page 14. Replace

fasteners; reinstall liner.

Replace liner as in Replacement

Procedure 1.

TPL Torn or damaged areas.

Loose bond at edges.

Worn cover.

Replace TPL as in Replacement

Procedure 1, Page 14.

Remove TPL as in Replacement

Procedure 1; replace two sided

tape attaching cloth cover to plastic

layers; reinstall TPL.

Remove TPL from helmet as in

Replacement Procedure 1; replace

TPL cover, reinstall TPL.

Earcup

Assembly

Cracked cup, broken or

missing tab, torn earseal,

worn earphone holder or

spacer pad, or failed

earphone.

Cleanliness.

Remove earcup as in Replacement

Procedure 3, Page 16; replace

parts as necessary; reinstall

earcup.

Clean per instructions on the next

page.

Retention

Assembly

(including

nape strap

and chinstrap)

Frayed or torn fabric,

loose stitching, corroded

or bent buckles or snap.

Cleanliness.

Replace as in Replacement

Procedure 2, Page 15.

Clean per instructions on the next

page.

Microphone,

Boom, Swivel

Assembly

Failed microphone;

damaged or worn swivel

or boom.

Replace assembly as in

Replacement Procedure 4,

Page 18.

Microphone

Cord,

Connector

Cuts, cracks, deteriorated

insulation, general

damage.

Replace as in Replacement

Procedure 5, Page 19.

Visor

Assembly

Cracks, scratches, loose

knobs.

Cleanliness.

Replace as in Replacement

Procedure 6, Page 21

Clean per instructions on the next

page.

13

Loading...

Loading...