Maintaining the equipment

Maintenance schedule

Move nozzle needle by at least one full stroke.

Visually inspect to ensure tightness.

Replace a leaky stuffing box.

Connections

Body gasket

Cone guide

Visually inspect for the following points:

Tightness

Cleanliness

Replace leaky or worn components.

Remove dirt.

Check that the actuator is securely seated on the

equipment and inspect bolts.

Tighten loose connections.

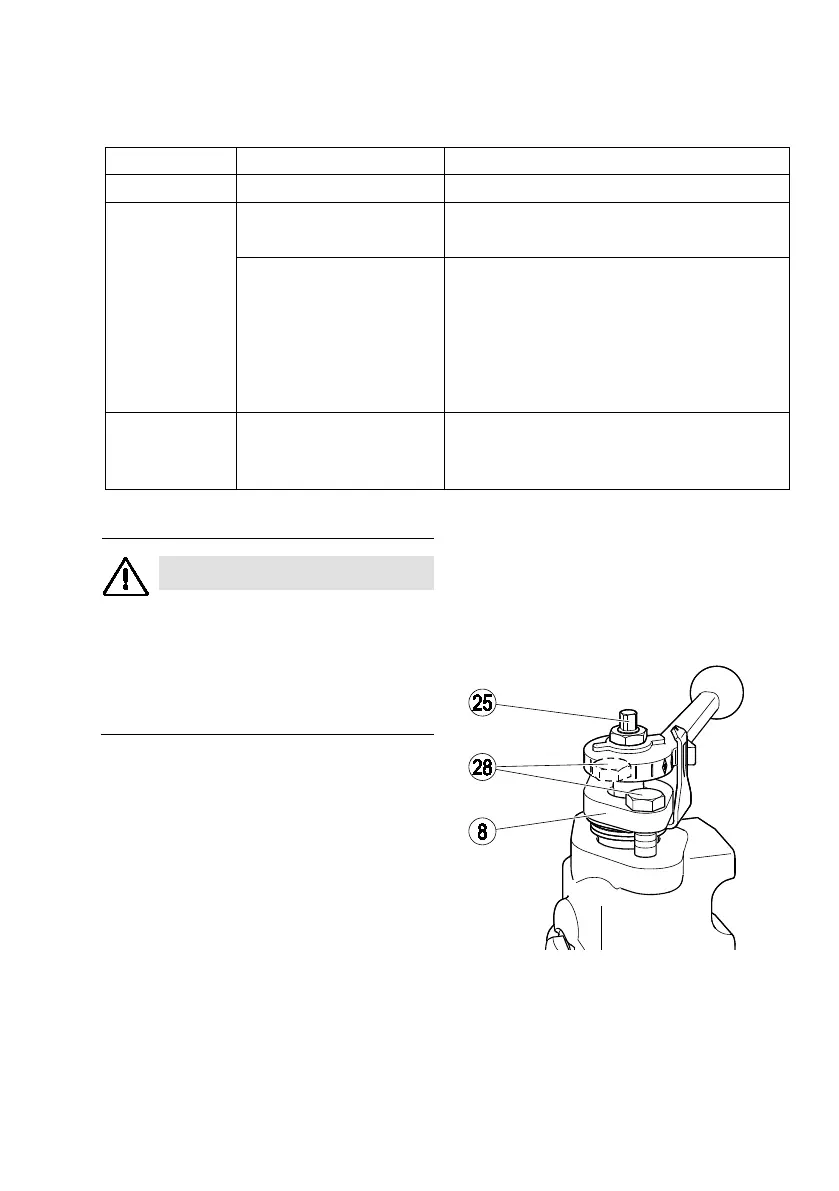

Retightening the stuffing box

Component parts that get hot during

operation can cause burnings.

Always wear thermally insulated and

heat resistant safety gloves when

operating the lever.

If fluid escapes via the stuffing box gland (8),

retighten the stuffing box bush.

Unscrew the nozzle needle (25) by a half turn.

The torque for the stuffing box screws varies

depending on the equipment:

For models with DN 15 to DN 32, the required

torque is 7 Nm.

For models with DN 40 and DN 50, the required

torque is 11 Nm.

Tighten the stuffing box screws (28) to the

specified torque.

Make sure the following conditions are satisfied:

The valve must be able to open and close.

No more fluid escapes from the stuffing box

gland.

If you are unable to eliminate the leak, replace

the stuffing box as described on page 30.

Loading...

Loading...