117807-05

GEZE GmbH

Reinhold-Vöster-Strasse 21–29

71229 Leonberg

Germany

Tel.: 0049 7152 203-0

Fax: 0049 7152 203-310

www.geze.com

Symbols and means of representation

Important information and technical notes are emphasised in order to illustrate

the correct operation.

Symbol Meaning

means "important note"

means "additional information"

X

Symbol for an action: Here you have to do something.

X

Observe the sequence if there are several action steps.

Product liability

In accordance with the liability of the manufacturer for their products as dened

in the German “Produkthaftungsgesetz” (Product Liability Act), the information

contained in this brochure (product information and proper use, misuse, product

performance, product maintenance, obligations to provide information and

instructions) is to be observed. Non-compliance releases the manufacturer from

its statutory liability.

2 TS 3000B

Guide rail with electromechanical hold-open device

2.1 General information

2.1.1 Product description

The guide rail system can electromechanically hold a door leaf in the open

position.

2.1.2 Intended use

The system is designed solely for use in dry rooms.

Any other use than the proper use as well as all changes to the product are

impermissible.

2.1.3 Limitation of liability

GEZE does not accept any liability for direct or indirect damage resulting from

the non-observance of the specications in these instructions of this product.

Technical modications that serve the improvement or further development

of the product can be introduced at any time without any particular

announcement.

GEZE shall not be liable for injuries or damage resulting from unauthorised

modication of the system.

GEZE is not liable if products from other manufacturers are used with GEZE

equipment. Only original GEZE parts may be used for repair and maintenance

work as well.

Please do not hesitate to contact the GEZE customer service for further

information.

2.1.4 Important information

The installation drawing, mounting instructions, maintenance and operating

regulations have to be observed.

The specied range of application has to be observed.

The prescribed mounting dimensions have to be observed.

The prescribed means of fastening have to be used.

All the screws have to be tightened as shown in the drawings.

After mounting and before commissioning:

X

Check the function.

X

Tighten all the clamping screws again.

X

Ensure free accessibility of the ttings for maintenance in accordance with

DIN18357.

X

Make sure that an acceptance test is carried out by qualied and authorised

personnel according to the applicable regulations.

X

In case of re or smoke protection doors, mount an acceptance test plate after

the successful acceptance test.

2.2 Safety instructions

X

The prescribed mounting, maintenance and repair work must be performed

by properly trained personnel authorised by GEZE (see "GEZE user

information for door closer").

X

The country-specic laws and regulations must be observed during safety-

related tests.

X

In accordance with Machinery Directive 2006/42/EC, a risk analysis must

be carried out and the system must be identied in accordance with CE

Identication Directive 93/68/EEC before commissioning.

X

Observe the latest versions of guidelines, standards and country-specic

regulations, in particular:

à BGR 232 “Guidelines for power-operated windows, doors and gates”

à DIN 18650 “Building hardware - Powered pedestrian doors”

à Accident-prevention regulations, in particular BGV A1 “General regulations”

2.2.1 Safety-conscious working

X

Observe the safety instructions for electrical systems and in the wiring

diagram.

X

Protect the workplace against unauthorised entry.

X

Take care to allow sucient space for the movement of components in the

system.

à Risk of injury when a drive is opened through sharp edges and moving parts

(drawing in of hair, clothing, …).

à Risk of injury by crushing, impact, shearing or drawing-in spots.

2.3 Technical data

Operating voltage 24 V DC ±15%

Current consumption 100 mA

Max. ripple permitted 30%

2.4 Description

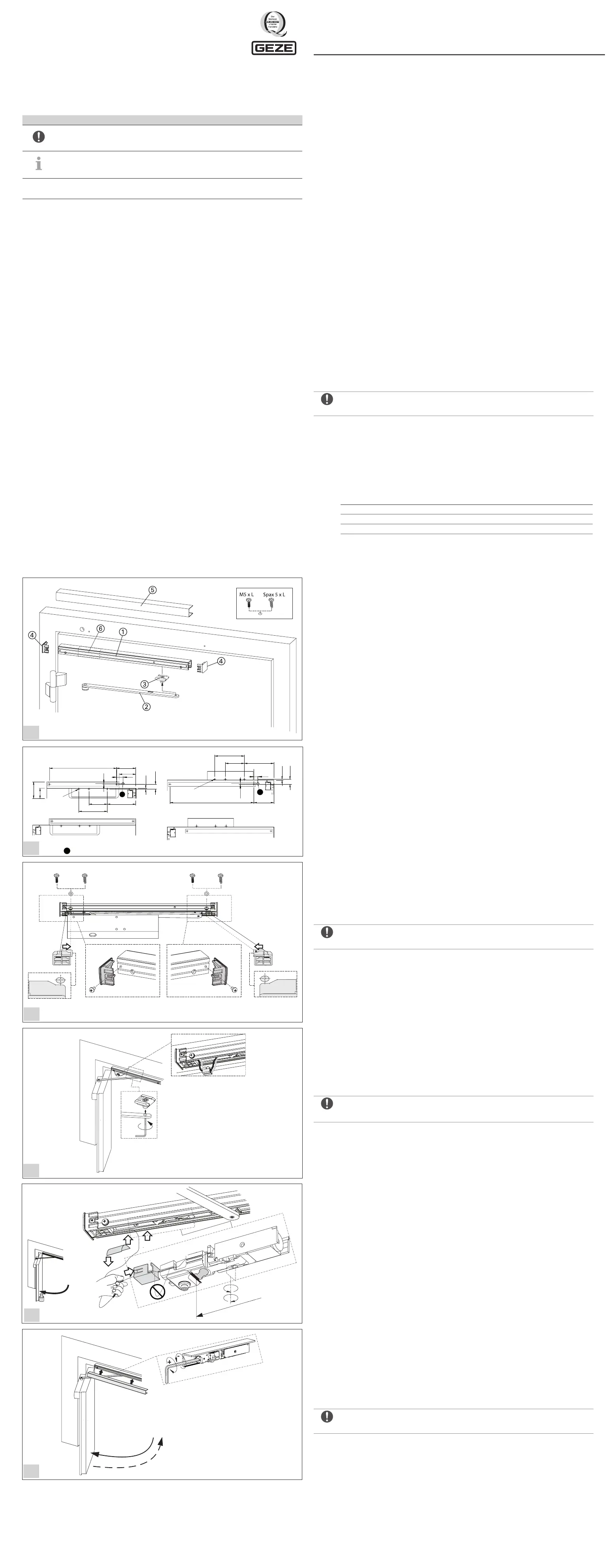

Designations in g. 9:

1 Guide rail

2 Sliding lever

3 Sliding block

4 End cap

5 Cover panel

6 Electromechanical hold-open device

2.5 Mounting the TS 3000B

2.5.1 Drilling pattern (g. 10)

TS 3000B with E guide rail for direct xing.

X

Mark and drill the xing holes for door closer and guide rail using the tting

template and cut the M5 thread if necessary.

X

Drill additional bore holes with Ø15 mm for cable entry as shown in g. 10.

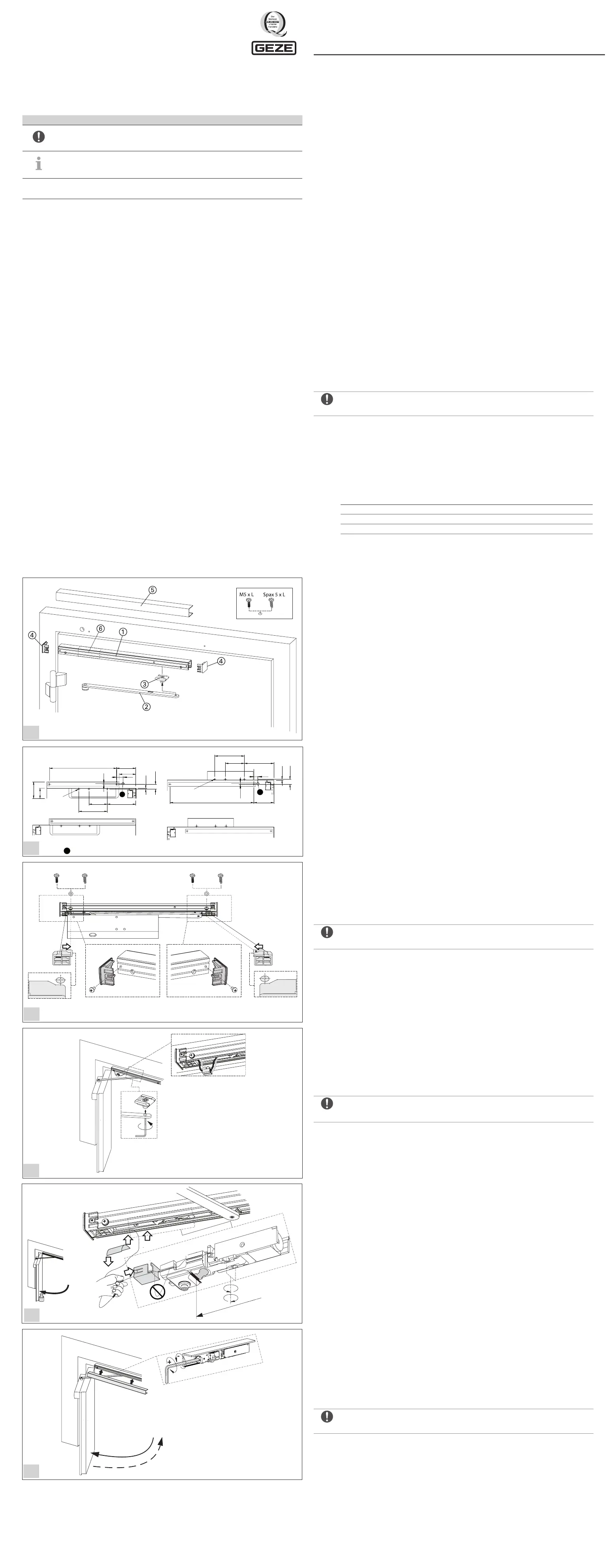

2.5.2 Mounting the guide rail and end caps (g. 11)

X

Make sure that the cable connection faces to the side of the door leaf.

X

Align spacers (1) at the guide rail.

X

Fasten the mounting screws (2) of the guide rail with 2 Nm.

X

Align and screw on the end caps (3).

X

Fasten the door closer.

2.5.3 Connecting the 24 V power supply (g. 12)

à Red = + (terminal 1)

à White = – (terminal 2)

X

Connect the 24 V cable to the luster terminal (1).

X

Connect the sliding lever (2) to the sliding block (tightening torque 5 Nm).

2.5.4 Adjusting the electromechanical hold-open device (g. 13)

X

Open door leaf (1) to desired open position and x it there.

X

Remove cable protection foil from guide rail (2).

X

Loosen clamping screws (3) of electromechanical hold-open device.

X

Move electromechanical hold-open device until catch contacts sliding block.

X

Securely fasten electromechanical hold-open device with screws (5).

X

To prevent loops, tighten cable and fasten cable protection at

electromechanical hold-open device end (6).

X

Place cable in cable protection and in upper cable chamber behind

electromechanical hold-open device (7).

X

Secure cable with cable protection foil (8).

2.5.5 Functional test of electromechanical hold-open device (g. 14)

X

Open door leaf (1) and engage it in the electromechanical hold-open device.

X

Set the manual release force (2).

Release force for door according to EN 1155:

à 40…120 Nm in an open position of 90°

X

De-energise the electromechanical hold-open device.

The door leaf closes (3).

X

Clip cover on (4).

9

A

ø15 mm Power supply (24 V DC)

RIGHT

LEFT

89

104

15499

154

M5

55

90

10

31.3

428.5

A

26

5 ±1

10

31.3

428.5

OPP HINGE RIGHT

104

154

99

154

M5

OPP HINGE LEFT

A

26

5 ±1

10

M5 x L

Spax 5 x L

M5 x L

Spax 5 x L

a

M4x8 M4x8

a

ss

d d

11

SW 3

a

s

12

kg

a

s

d

f

g

h

j

k

13

+

-

SW 5

a

s

d

f

14

Loading...

Loading...