However, be sure to check for damaged parts, loose

nuts and bolts, especially ground wires which could

have occurred in transit.

GROUND: All portable generators must be grounded.

The ground terminal on the generating set should

always be used to connect the set to a suitable ground.

The ground path should be #8 size wire, connected to a

1” copper pipe or steel rod, penetrating into the ground

approximately 10”. Connect copper ground clamp to

the pipe and connect a #8 AWG between this clamp

and the gen-set negative ground clamp.

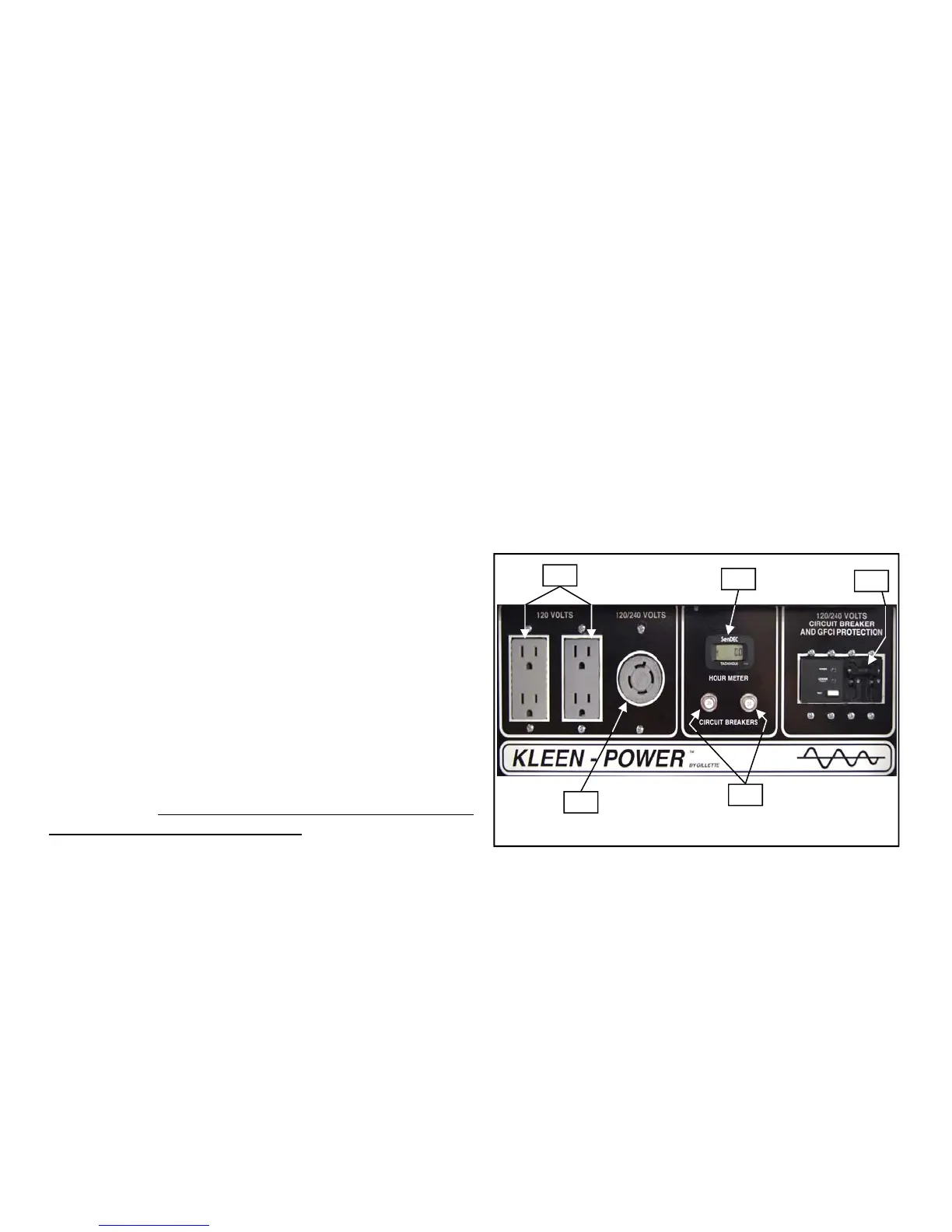

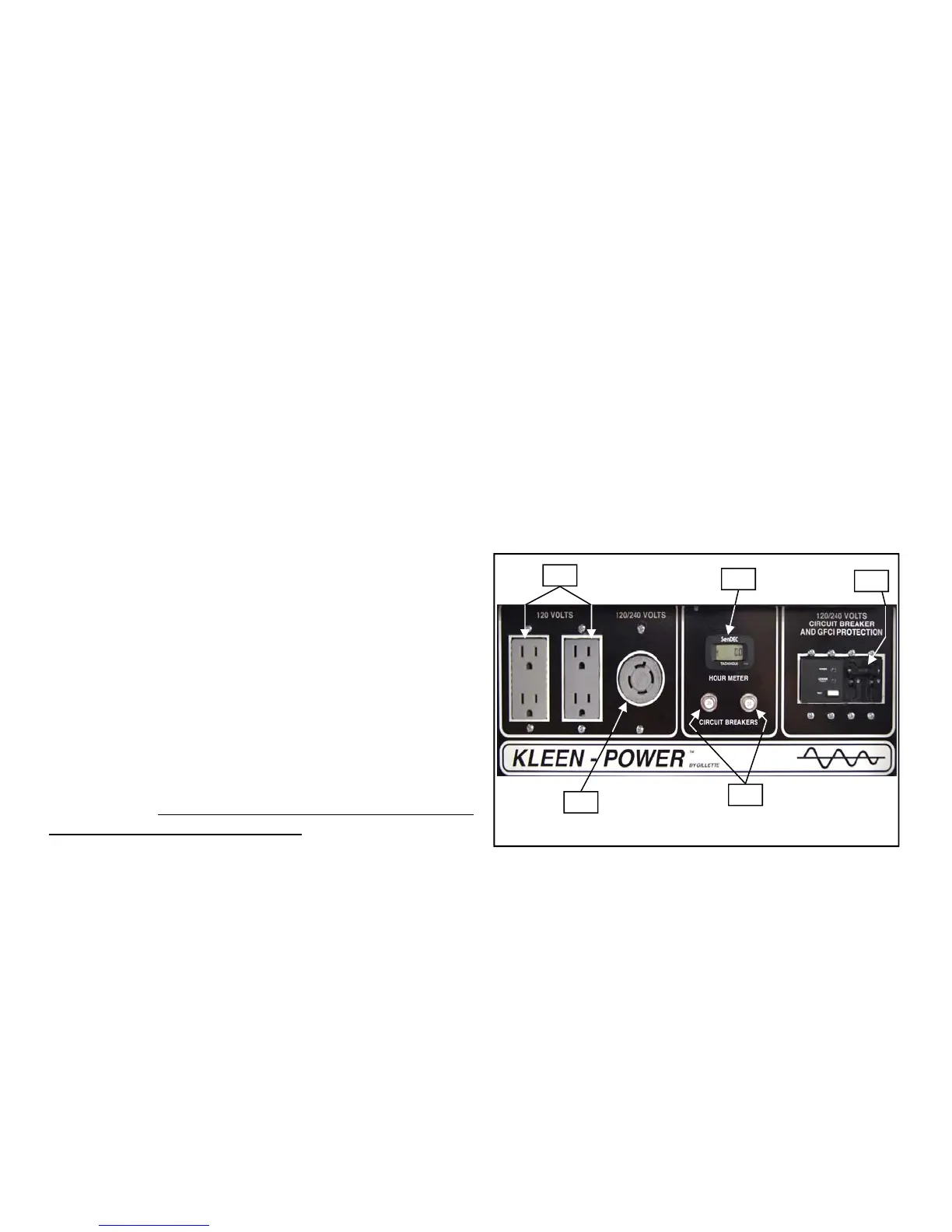

LOCATE AND BE FAMILIAR WITH THE

FOLLOWING ITEMS ON RECEPTACLE

PANEL FOR SINGLE CYLINDER GEN-SET

AND RECEPTACLE PANEL ON V-TWIN

GEN-SET.

Most generator sets will have a receptacle panel with a

variety of components, depending on the specific

generator set. It is important to know that all

receptacles conform to National Electrical

Manufacturer's Association (NEMA) regulations and

matching NEMA male caps should always be used.

Always use grounded male plugs. The neutral line of

generating set is mechanically grounded to frame.

CIRCUIT BREAKER: All portable single phase

generating sets have automatic trip, circuit breakers to

protect against electrical overloads. If possible, it is

advised to switch off or remove electric load before

starting engine.

BALANCED LOAD: This exclusive and patented

special winding design will automatically not allow an

unbalanced electric load condition while using a large

120 volt load, thereby allowing full KW generator power

on any 120 or 240 volt receptacle.

ENGINE STOP SWITCH: Some models have the

engine stop switch on the receptacle panel and some

models have this stop switch located on the engine.

Always locate this switch and be familiar with its

location before operating the set.

HOUR METER: All GPE models indicate the hours of

use to help in determining service periods. This

particular generator has the following features:

1) HOUR METER: Calculates and totals the entire

running time of gen-set. This is particularly helpful in

determining service periods of the engine.

2) TACHOMETER: This meter is part of the hourmeter

and is functional when small push button on hourmeter

housing is depressed. It calculates and displays the

speed of gen-set, which is set at 3750 RPM, at no

load. NOTE: There is no voltmeter on operator’s

panel to determine voltage output, due to short life of

meter mechanism undergoing normal engine

vibration. However, the engine speed set at 3750

RPM equates to 125/250 volts at no load.

3) TWO SERVICE ALERTS: At each 25 hour run

time of engine, the service alert “CHG OIL & FILTER”

AND “SVC ENG AIR CLEANER” will appear on the

tachometer.

4) There is a mode button on meter bezel of

tachometer, that allows repair/operator to scan the

various alerts (hourmeter, tachometer, and (2)

service alerts). Simply press the mode button for

each topic of information. Once service is complete,

the mode button should be pressed to show the

tachometer reading. The engine speed should be

adjusted to run at no load, 3750 RPM. This speed

equates to the correct generator voltage of 125/250

at 61-62 hertz, and replaces the need of the short

lived voltmeter.

Page 4

1) STANDARD 120 VOLT, 15 AMP, NEMA 5-15R RECEPTACLE

2) STANDARD 120/240 VOLT 20 OR 30 AMP NEMA L14-20R OR

NEMA L14-30R TWIST-LOCK, 4 WIRE RECEPTACLE.

3) PUSH BUTTON, THERMO RE-ACTING MAIN CIRCUIT BREAKER

4) TWO POLE MAGNETIC RE-ACTING MAIN CIRCUIT BREAKER

WITH BUILT-IN GFCI PROTECTION (See note below).

5) RUN TIME METER

NOTE: GILLETTE EXCLUSIVE, COMBINATION MAIN LINE CIRCUIT

BREAKER AND GROUND FAULT CIRCUIT INTERRUPTER, BUILT

INTO ONE PIECE CONSTRUCTION. SEE PAGE 10 FOR ADDI-

TIONAL GFCI INFORMATION.

GEN-SET PANEL FOR 5.5 THRU 7.5 KW

#1

#2

#3

#5

#4

Loading...

Loading...