NOTES: Explanation of notes 1, 2, 3, & 4

Note (1): Make sure that generator

produces no more than 10% harmful harmonic wave-

form distortions or possible destruction of these loads

may result. Whenever gen-set is in a service station,

ask for a printout on generator produced sine wave.

Your generator produces approximately 5-6% harmonic

distortions

Note (2): Hard-starting motors require starting

watts of 3 to 4 times the rated running watts, due to the

design of electric motor.

Note (3): These loads may require up to l5

minutes to restart due to its normal build up of

compressor head pressure.

Note (4): These are extremely hard starting

Code L electric motors and they require 6 to 8 times

name plate running amps for total starting load.

NOTE: Consult dealer on extremely hard to start motor

loads such as air conditioners and air compressors, and

submersible water pumps.

7. BEFORE STARTING.

A. Disconnect all electrical loads.

B. Make sure the generating set is positioned on firm

level surface.

C. Check the lubricating oil and maintain to proper

level. CAUTION: Never start engine when oil level is

below normal level or when oil fill cap is off.

D. Check fuel level and fill tank. Tank should be 3/4

full with clean fresh unleaded automotive gasoline.

Never fill fuel tank completely to the top. Always wipe

up and remove any spilled gasoline. Gasoline

soaked rags must be disposed of in flame proof

containers.

E. Make sure that exhaust is directed to outside area

void of people, or animals.

F. All generator control panels are equipped with

automatic GFCI (Ground Fault Circuit Interrupter)

stop feature. If a ground fault exists (potential electric

shock hazard), all receptacles will not produce power.

Notice, the test push button and (2) test lights (See

Note 2 and 3) on the circuit breaker module, as

pictured on page 10.

8. STARTING.

A. Open the On-Off fuel valve underneath the fuel

tank.

B. Close the manual choke. Adjust this choke

according to engine manual, for best operating

conditions. When the engine is already warm or it is

a warm day, you may only have to close the choke

half way, or not at all.

C. Move engine start-stop switch to start position.

This switch is almost always mounted on the engine,

and it can be a toggle switch, a rotary switch, a key

switch, or a stop-start switch.

D. Firmly grasp the starting rope handle and slowly

pull it out. The resistance becomes hardest at a

certain point corresponding to the engine

compression point. Let the rope rewind itself from

this point, then pull sharply. Repeat process if engine

fails to start. CAUTION: Do not pull the rope all the

way to the end. Do not release the rope handle after

pulling. While still holding on, allow the rope and

handle to rewind slowly into its housing.

CAUTION: It is possible to cause arm and back

injury if starting rope is pulled in a reckless or

hazardous manner.

E. When the engine starts, open the choke slowly.

CAUTION: Allow generating set to run at no load for

five (5) minutes upon initial start-up to permit engine

and generator to warm up and stabilize.

F. Check the generating set for abnormal noises or

burn smells. If OK, connect the load to the

generating set. CAUTION: Do not apply full heavy

electrical load during the first three (3) hours on your

brand new set. Allow the engine to have its normal

Page 7

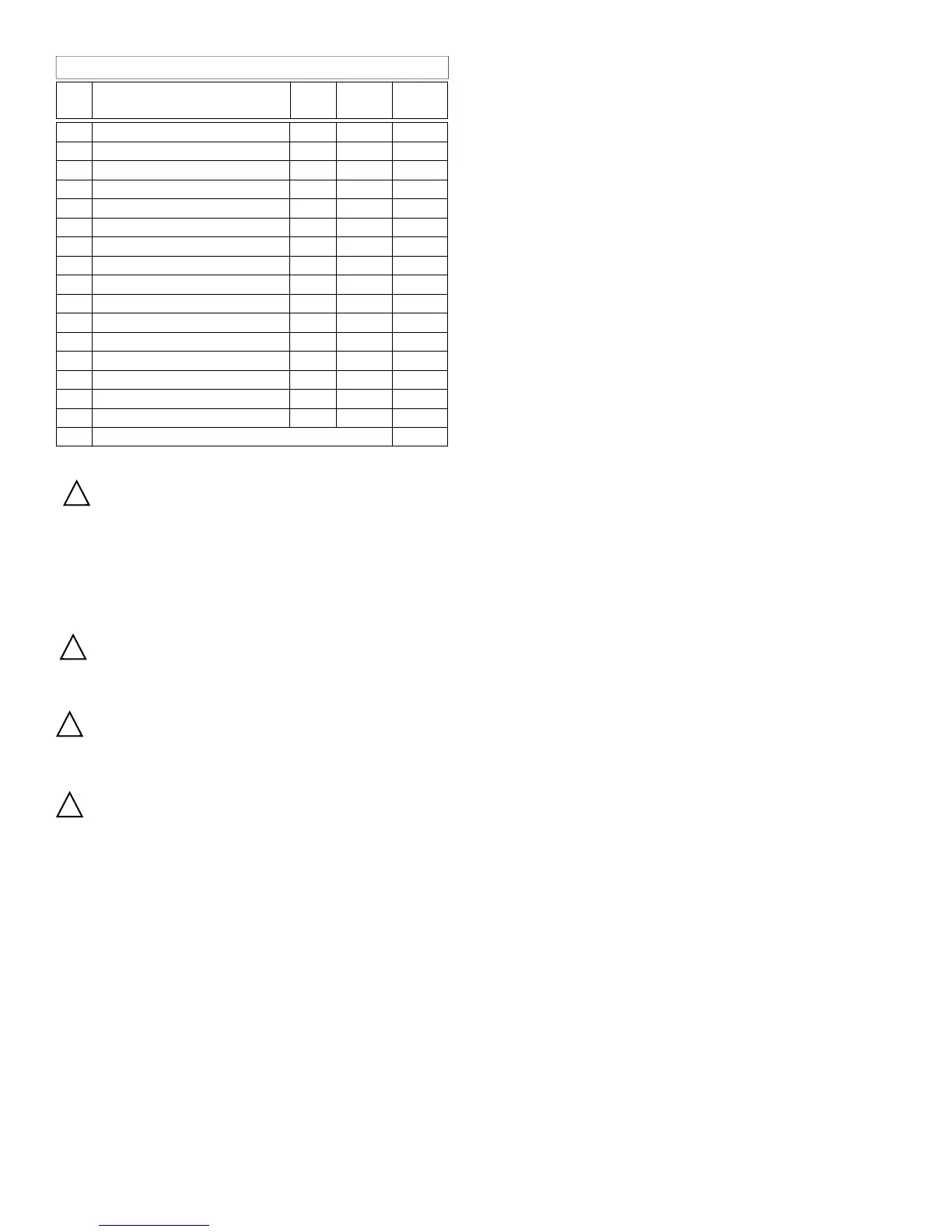

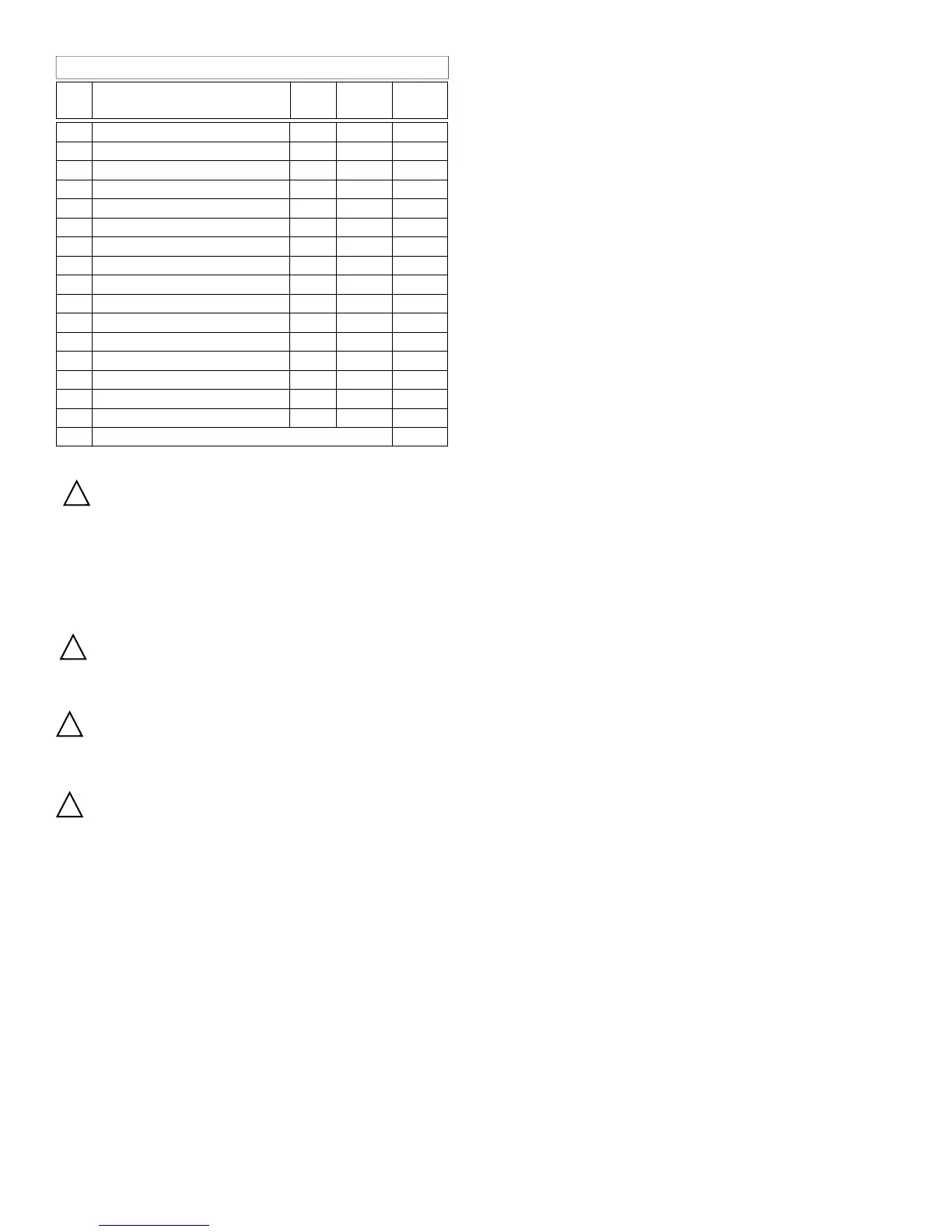

Sump Pump, 1/3 hp (2) 500

Refrigerator (3) 600

Furnace Fan, 1/3 hp

(2) 600

Freezer (3) 800

Jet Water Pump, 3/4 hp (2) 900

Electric Stove Element 1000

Submersible Water Pump, 1hp

(4) 1000

Toaster 1000

Coffee Maker 1200

Dishwasher 1200

Hair Dryer 1200

Microwave Oven (1) 1500

Submersible Water Pump, 2 hp

(4) 1600

Water heater 3000

Oven 4500

Air Compressor on 120V (3) (4) 1800

Total Watts Checked

RUNNING TOTAL

APPLIANCE NOTES

WATTS WATTS

DETERMINING ALTERNATOR LOAD REQUIREMENTS (cont.)

!

!

!

!

Loading...

Loading...