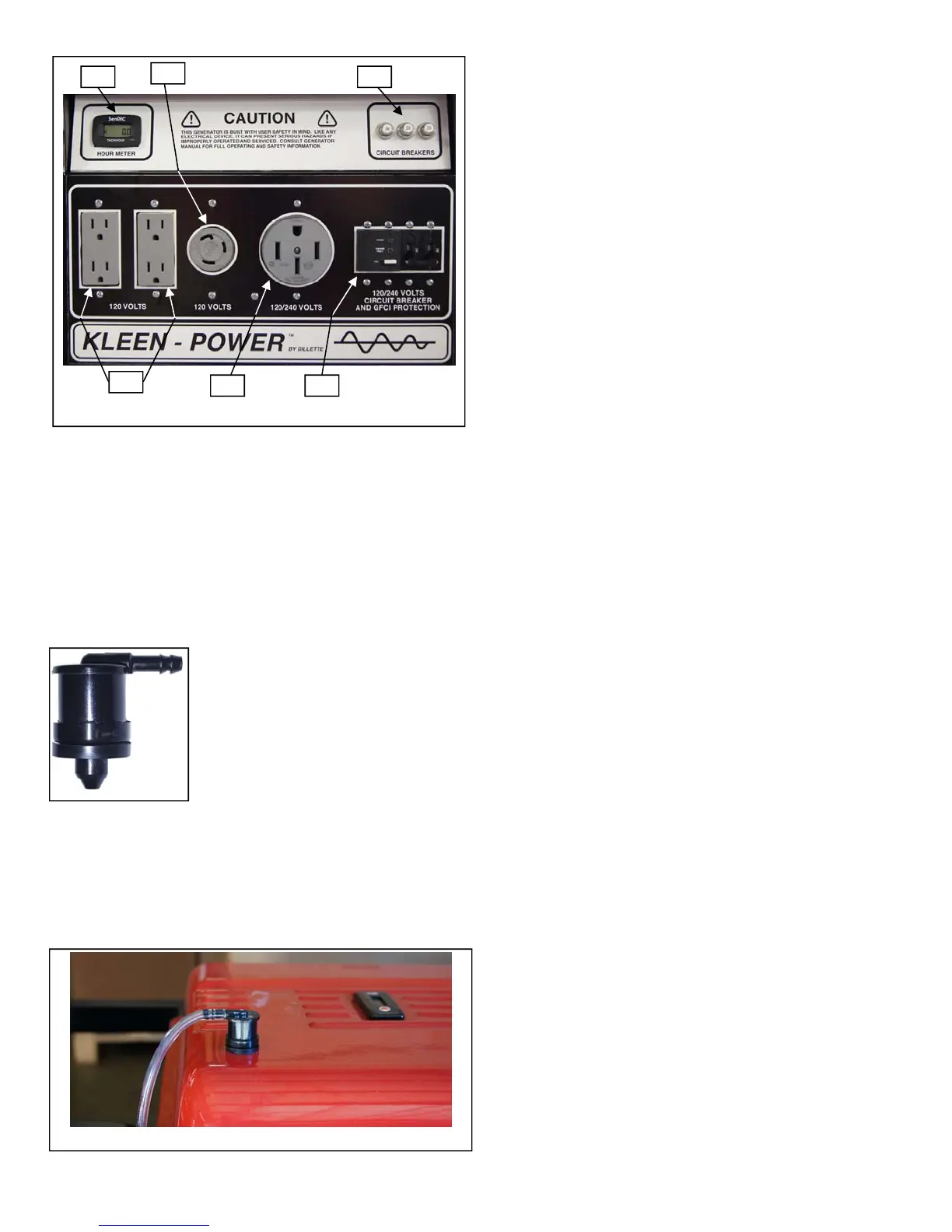

SLOSHING VALVE: EPA requires a device that

captures fuel tank fumes (not

allowing fumes to escape into the

atmosphere) and direct them to the

engine air cleaner. This valve is

mounted on top of gen-set fuel tank,

where excess gasoline fumes

accumulate. Occasionally, when gen

-set is transported, the fuel can

“slosh” and actually enter into the air cleaner. This

“sloshing” valve prevents the passage of fuel fluids

while allowing vapors to proceed to the engine air

cleaner. The valve is made of plastic and may be

vulnerable to breakage in construction applications.

The engine protective cover will help protect this valve

from destruction.

CAUTION: If fuel tank is filled completely full, beyond

the “full fuel line”, or if air vent hose is “kinked” shut,

or if gen-set is operated on a severe slant, the fuel

tank venting is stopped. Under this condition, the non

-venting of fuel tank may cause internal pressures

that can actually collapse the fuel tank, beyond

repair.

FUEL VALVE: The generator fuel tank has an ON-

OFF valve and filter screen system mounted

underneath tank. Always keep this valve closed

when the set is not in use, or in transit.

FUEL GAUGE: All models have fuel level indicator

built into the extended run fuel tanks. You can always

safely monitor fuel level on all tanks without cap

removal.

FUEL CAP: Fuel cap should be opened only when

refueling the tank. When replacing the cap, be sure

to turn cap clockwise until cap locks in place.

OIL-GUARD: All models have protection against

damage to engine resulting from low oil level. As the

oil level falls below safe level, the engine

automatically shuts down and the engine will not

restart, until oil is added. Continually, check the oil

level dip stick on engine, to avoid this situation.

6. LOAD APPLICATION:

Determine the total electric load before it is

connected to generating set to prevent overloading.

Always compare the generating set nameplate data

with that of the equipment to be powered by the

generator set to insure that watts, volts, amperage

and frequency requirements are suitable for operating

equipment. Generally, the wattage listed on the

equipment nameplate is its rated output. However,

some equipment may require three to ten times more

wattage than its rating on the nameplate, as the

wattage is influenced by the “plugged-in” equipment

efficiency, power factor and starting system. NOTE;

If wattage is not given on equipment nameplate,

approximate wattage may be determined by

multiplying nameplate voltage by nameplate

amperage, as found on the “plugged in” equipment.

VOLTAGE X AMPERAGE = WATTS

When connecting a resistive load such as

incandescent lights, heaters or common electric

power tools, a capacity of up to the generating set full

rated wattage output can be used. When connecting

a fluorescent or mercury light, transformers, inductive

coils, or electric motors a capacity of up to the

generating set full rated wattage output, multiplied by

0.6 can be used.

Page 5

FUEL TANK “SLOSHING” VALVE INSTALLED

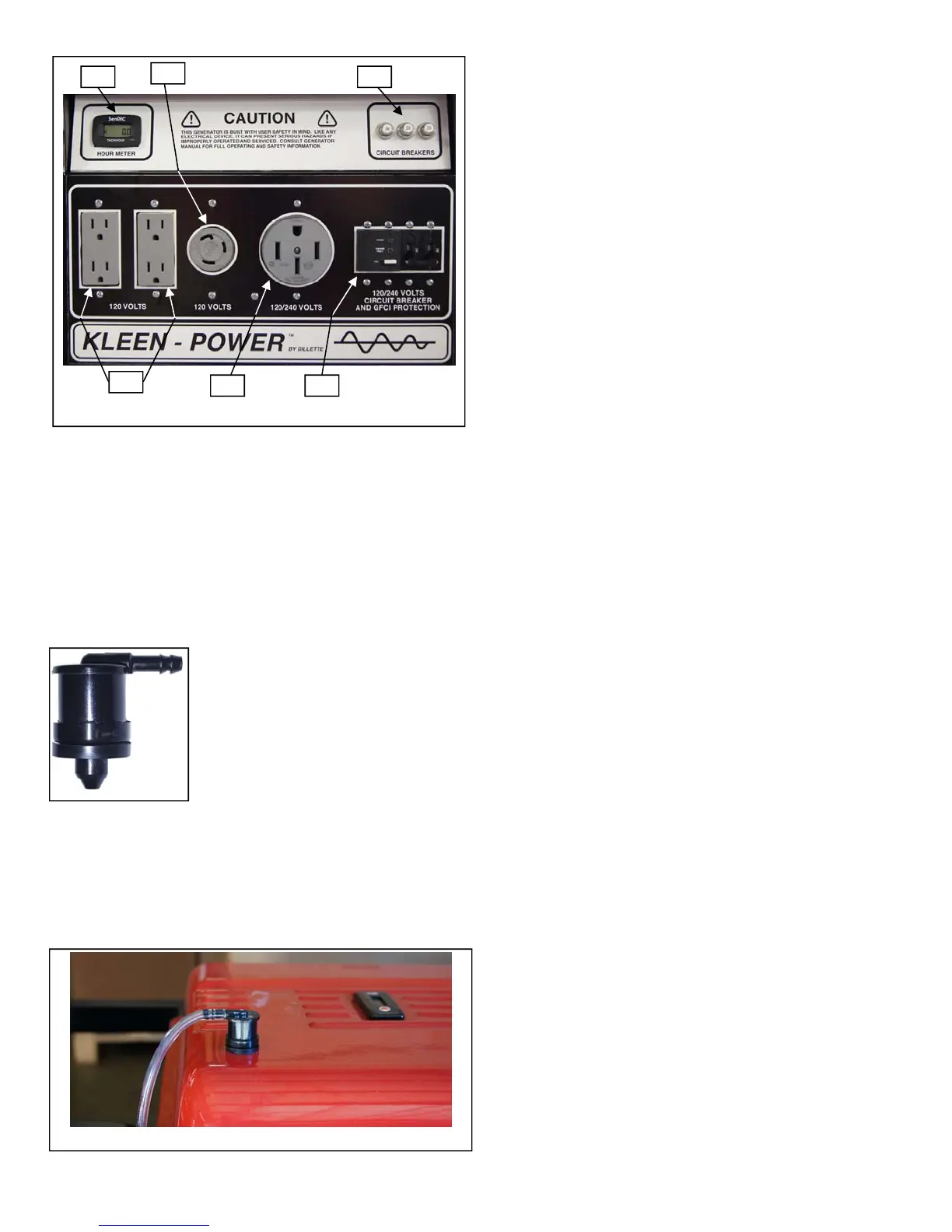

GEN-SET PANEL FOR 9.5 THRU 15.0 KW

#1 #2

#3

#5

#4

#6

1) RUN TIME METER

2) INDIVIDUAL PUSH BUTTON CIRCUIT BREAKERS

3) NEMA 5-20R, 120 VOLY DUPLEX RECEPTACLES

4) STANDARD 120 VOLT, 30 AMP TWIST-LOCK RECEPTACLE

5) STANDARD 120/240 VOLT, STRAIGHT BLADE RECEPTACLE

6) TWO POLE MAGNETIC RE-ACTING MAIN CIRCUIT BREAKER

WITH BUILT-IN GFCI PROTECTION (See note below).

NOTE: GILLETTE EXCLUSIVE, COMBINATION MAIN LINE CIRCUIT

BREAKER AND GROUND FAULT CIRCUIT INTERRUPTER, BUILT INTO

ONE PIECE CONSTRUCTION. SEE PAGE 10 FOR ADDITIONAL GFCI

INFORMATION.

SLOSHING

VALVE

Loading...

Loading...