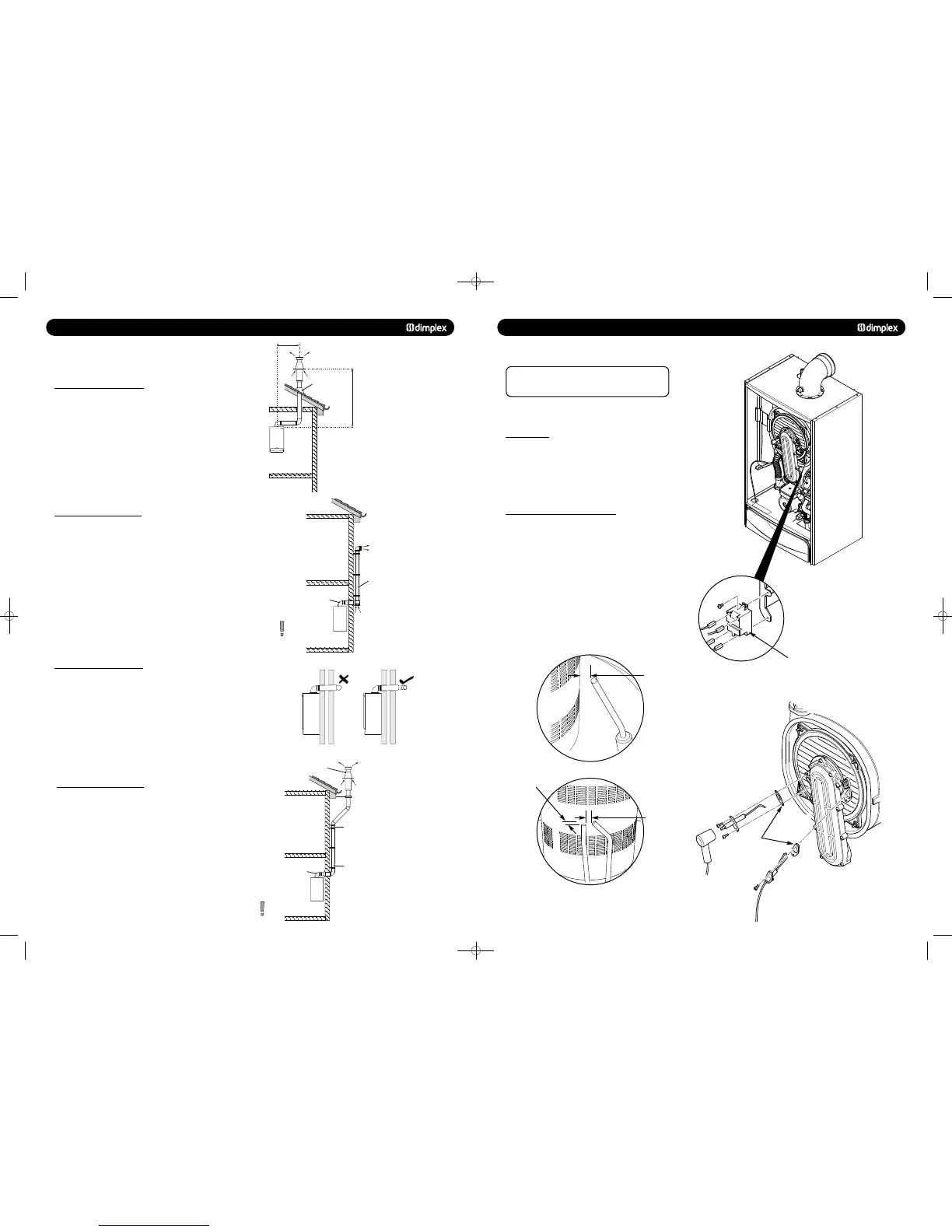

8.0 FLUE OPTIONS

8.5 Kit C Horizontal Anti-Plume Flue Kit

(C13) - Part No. 956084

If the standard horizontal terminal is likely to cause nuisance to

a neighbour or buildings, because of excess pluming, then this

particular flue kit raises the flue gas outlet point to a higher

elevation with the minimum amount of changes. The flue gas

duct is teed-off from the concentric part and covered by an

80mm outer tube to protect the flue duct from freezing. The

air in-take remains at the lower level (see Fig. 24).

If choosing this option then the external flue duct length

should be taken into account when calculating equivalent flue

length.

For installation details refer to the flue kit instructions.

Dimensions from vertical terminals to opening windows should

be in line with Fig. 19.

(For use with Standard horizontal telescopic flue kit - Part no.

956120 - only).

This kit is provided to assist in fitting a condensing boiler with

reduced clearances when fitted in good practice according to

the Guide to Condensing Boiler Installation published by

DEFRA/HMSO.

This kit allows the boiler f

lue outlet to be directed to the left

or to the right only.

Suitable for installations if the appliance cannot be repositioned

and where other horizontal flue options may cause some

nuisance to neighbours or buildings. The flue kit contains some

additional 45° elbows and extension ducts as well as a special

wall bracket to pass the guttering (see Fig. 26). The concentric

flue will be routed vertically alongside the outside wall to

above the roofline. Special seals are required to prevent

rainwater penetrating the pipe joints.

For installation details refer to the flue kit instructions.

8.6 Plume Diverter Terminal Kit

Part No. 956103

8.7 Kit D External Vertical Flue

(C33) - Part no. 956085

93 flanged elbow (concentric)

with sampling point

Raised external flue outlet kit -

Part no. 956084

Kit C

Raised Ø60mm flue

outlet duct with

Ø80mm anti-freeze

pipe.

Max height of raised

flue from top of boiler

to centre of outlet 8.5m

Min height 1m.

Standard horizontal flue

adaptor has an already

built-in fall in the flue to

allow the condensate to

drain away.

93 flanged elbow (concentric)

with sampling point

Max. lengths (from top of

boiler to AIR COWL 8m

Min. length 1m.

Kit D

Ø60/100mm concentric

air/flue pipe -

Part no. 956093

(1m extension)

and

Part no, 956092

(0.5m extension)

For outside installations

the pipe joints have to

be covered with special

“lip-seal” to prevent

rain ingress.

Ensure all horizontally fitted

pipes are routed with a

2.5-3° fall towards the boiler.

External vertical flue kit - Part no. 956085

Roof terminal

with rain cover.

Roof terminal

with rain cover

and pitched roof

flashing kit.

b

a

8.4 Offset Vertical Flue Terminal

(C33) - HBL Part 956081

‘a’ measured from boiler flue outlet centre line to the centre

line of the extension elbow.

‘b’ measured from the top of the boiler to the underside of the

air cowl.

Maximum allowable length of a + b = 8900mm

Fig. 23

Fig. 24

Fig. 25

Fig. 26

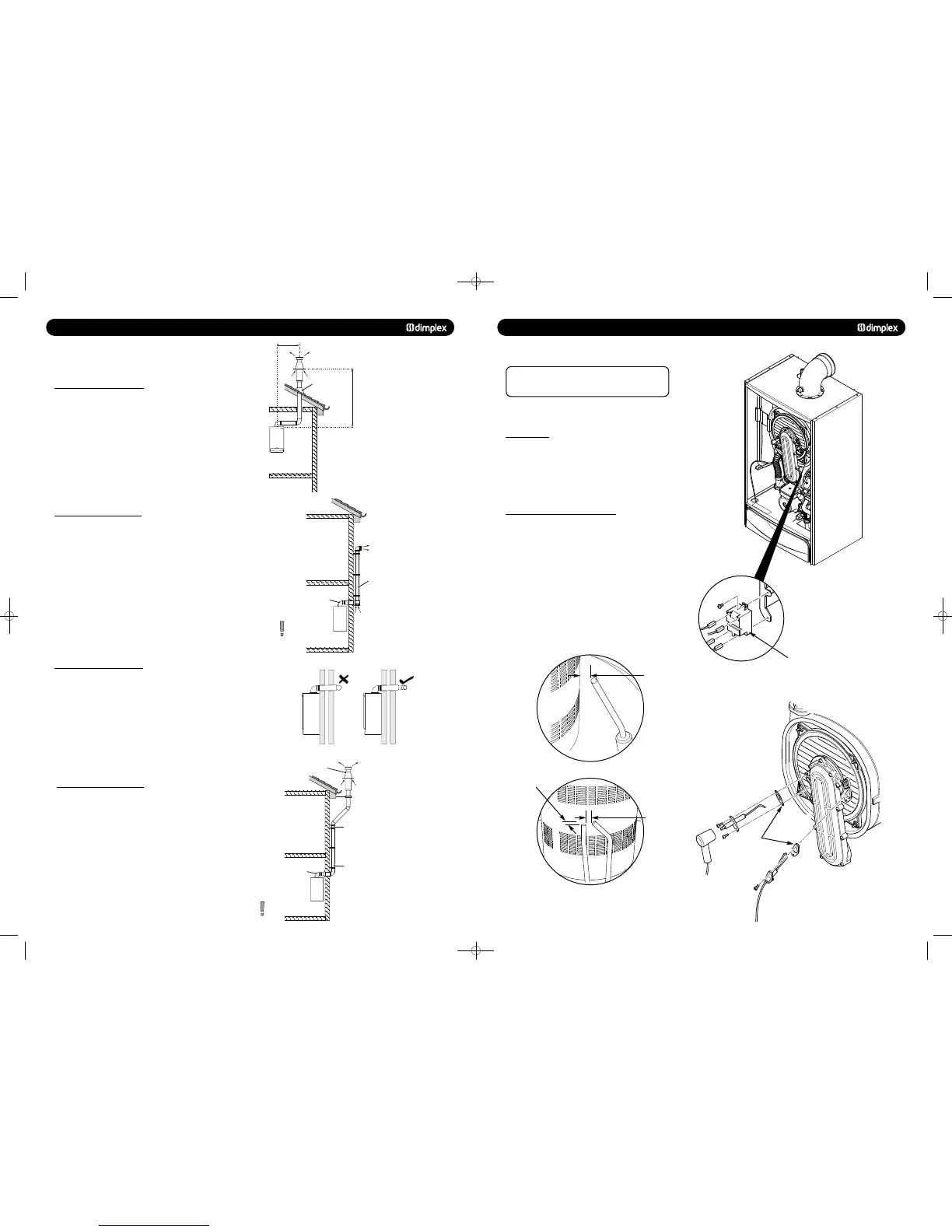

13.0 CHANGING COMPONENTS

IMPORTANT:

When changing components ensure that both

the gas and electrical supplies to the boiler are isolated

before any work is started.

See Section 12 : “Annual Servicing” for removal of case, panel,

door etc.

© Dimplex Boilers 2008

1. Disconnect the two feed wires, earth wire and electrode

lead noting their positions (Fig. 53).

2. Undo the two screws securing the igniter to its bracket and

remove the igniter. Reassemble in reverse order.

13.2 SPARK AND SENSING ELECTRODES

1. Disconnect the electrode leads, noting their positions

(Fig. 56).

2. Using a 3mm Hex key, remove the retaining screws securing

each of the electrodes to the burner door and remove the

electrodes.

3. Check the condition of the sealing gaskets and replace if

necessary. Reassemble in reverse order and then check that

the electrode gaps are as shown in Fig. 54 & 55.

Fig. 53

Fig. 54

Fig. 55

Fig. 56

Igniter

Gasket

6mm ± 0.5

to Burner

4mm ± 0.5

10mm ± 0.5

751262 MANUAL 19/10/10 08:41 Page 18

Loading...

Loading...