9.0 INSTALLATION

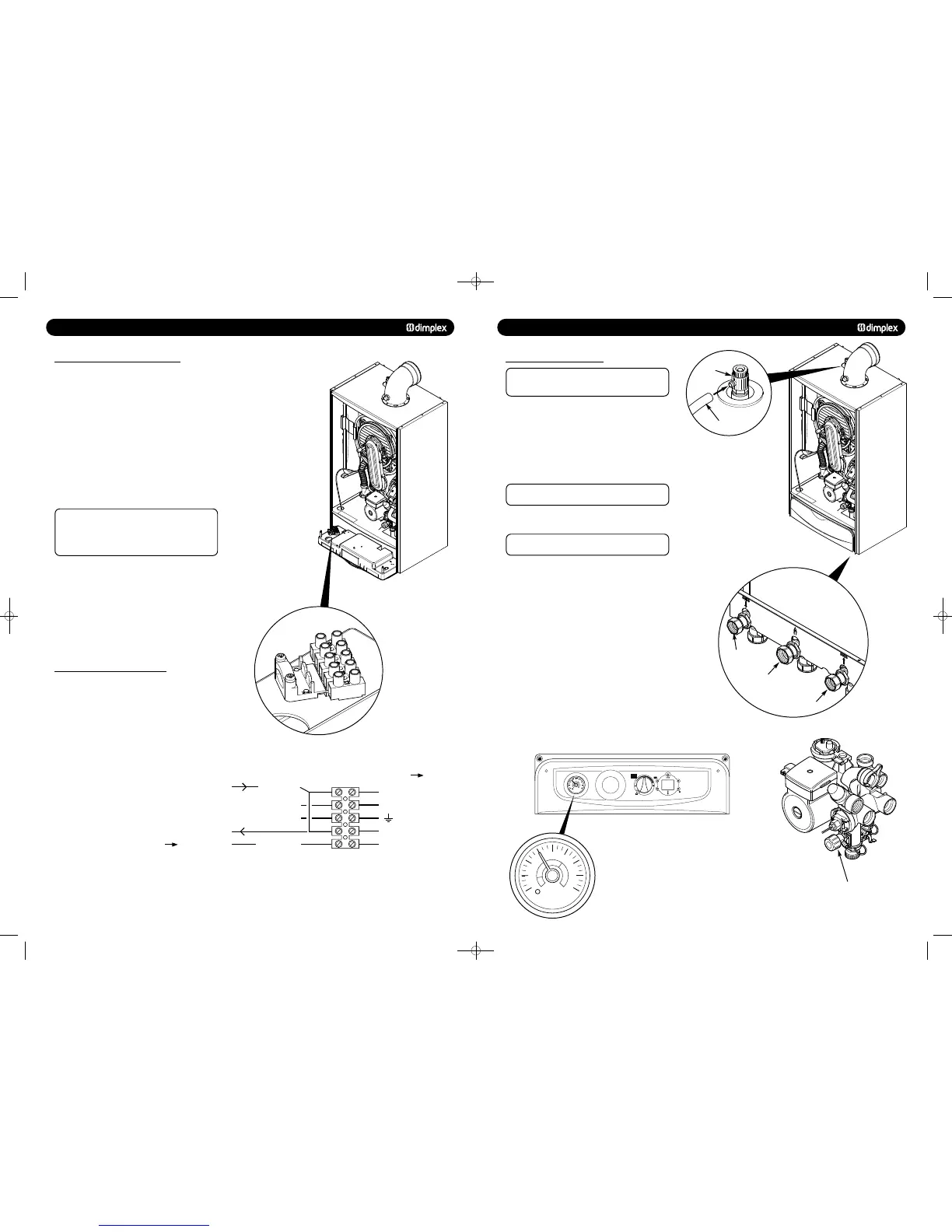

9.6 MAKING THE ELECTRICAL CONNECTIONS

The boiler is fitted with a 1.5m length of 3 core cable. This

can be connected to the fused 3A 230V 50Hz supply.

To connect an external control proceed as follows:-

1. Lower the drop down door.

2. Remove the two screws holding the controls box and ease

the box away from the boiler. The electrical connections are

made at the left hand side on the rear of this box.

3. Slacken the cable clamp on the terminal block (Fig. 36).

Insert the external control wiring through the clamp and route

it to the terminal block. Tighten the cable clamp.

4. Refer to the instructions supplied with the control.

be suitable for

230V switching.

Ensure that the external control input cable (s) have

sufficient slack to allow the control box to drop down.

5. Route external control cables away through the mains cable

grommet supplied.

9.7 PRELIMINARY ELECTRICAL CHECKS

1. Prior to commissioning the boiler preliminary electrical

system checks should be carried out.

2. These should be performed using a suitable meter, and

include checks for Earth Continuity, Resistance to Earth, Short

Circuit and Polarity.

L1 brown

L2 red

green/yellow

green/yellow (earth)

Fused supply 3A

230V~50Hz

brown (live)

red linkwire230V - Switch Live

230V - To external control

Permanent live

blue (neutral)

N blue

L3 orange

Connect external control using L2 & L3

Disconnect link wire

To boiler

10.0 COMMISSIONING

10.1 COMMISSIONING THE BOILER

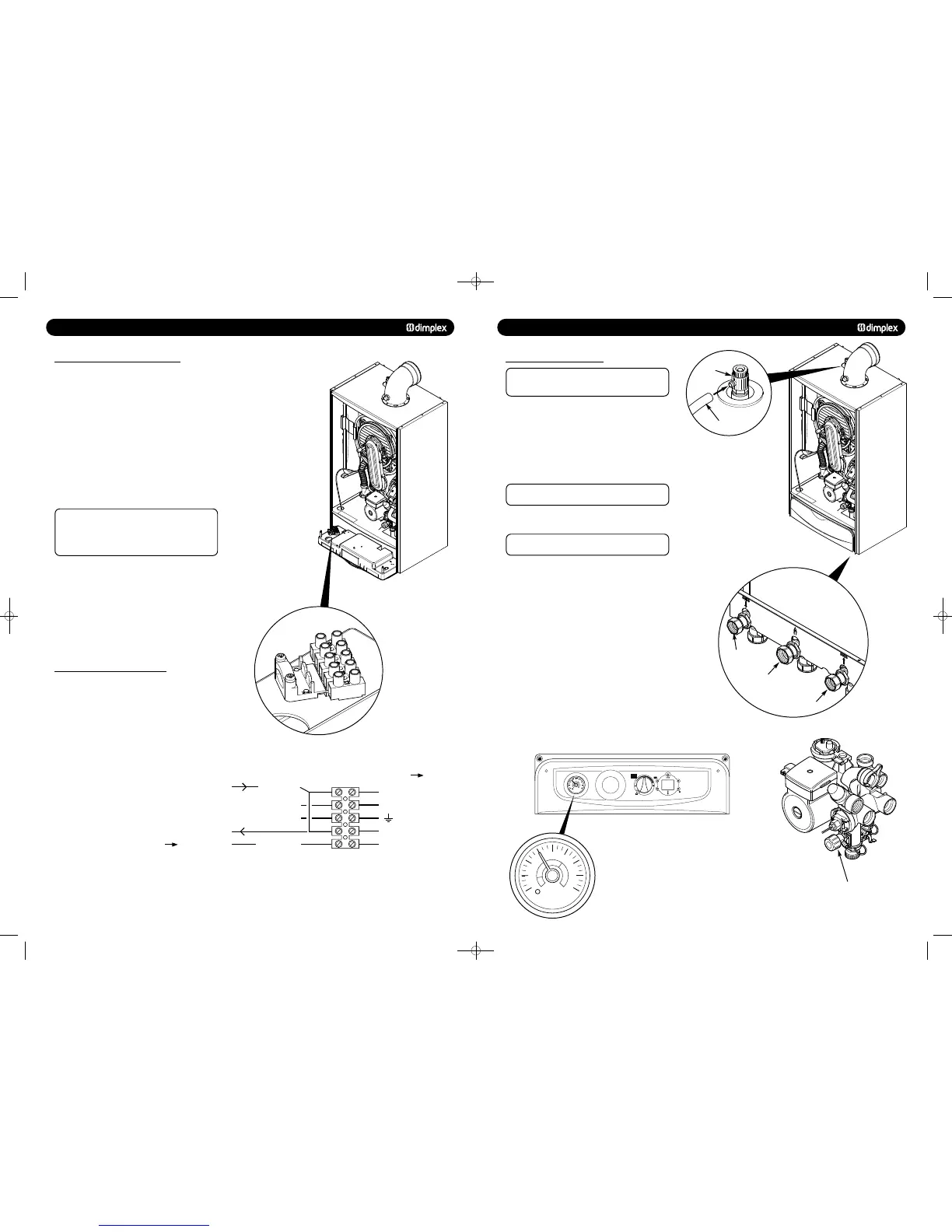

IMPORTANT: The air vent on top of the boiler must be

OPEN when filling

the system. Attach a tube to the air vent

to safely collect any excess water (Fig. 38).

Gas Soundnes

1. Ensure the gas service cock on the boiler is turned on

(Fig. 40). The entire gas installation must be tested for gas

tightness and purged in accordance with BS6891.

2. Open the service cocks to the CH flow and CH return

supplies.

3. Connect the filling loop and fill and vent the CH system.

Ensure the boiler is completely vented using the

manual air vent on top of the boiler.

4. Drain, flush and refill the boiler and system in accordance

with BS7593 (Fig. 30).

Failure to flush the system and to add inhibitor will

invalidate the appliance warranty.

5. Pressurise the system to 1.5 bar (Fig. 42).

Electrical Safety Checks on the Controls System

and Boiler

6. Carry out earth continuity, resistance to earth, short circuit

and polarity checks using a suitable meter.

7. Switch on the electricity supply to the boiler.

8. Set the controls to call for heat. The boiler will now operate.

Check the system for correct operation.

9. Replace the outer door and two securing screws.

© Dimplex Boilers 2008

Fig. 39

Fig. 38

Fig. 40

Fig. 41

Fig. 42

Fig. 43

CH Return

CH Flow

Gas Inlet

Boiler Drain Point

0

1

2

bar

3

4

751262 MANUAL 19/10/10 08:41 Page 24

Loading...

Loading...