18

0020008153A

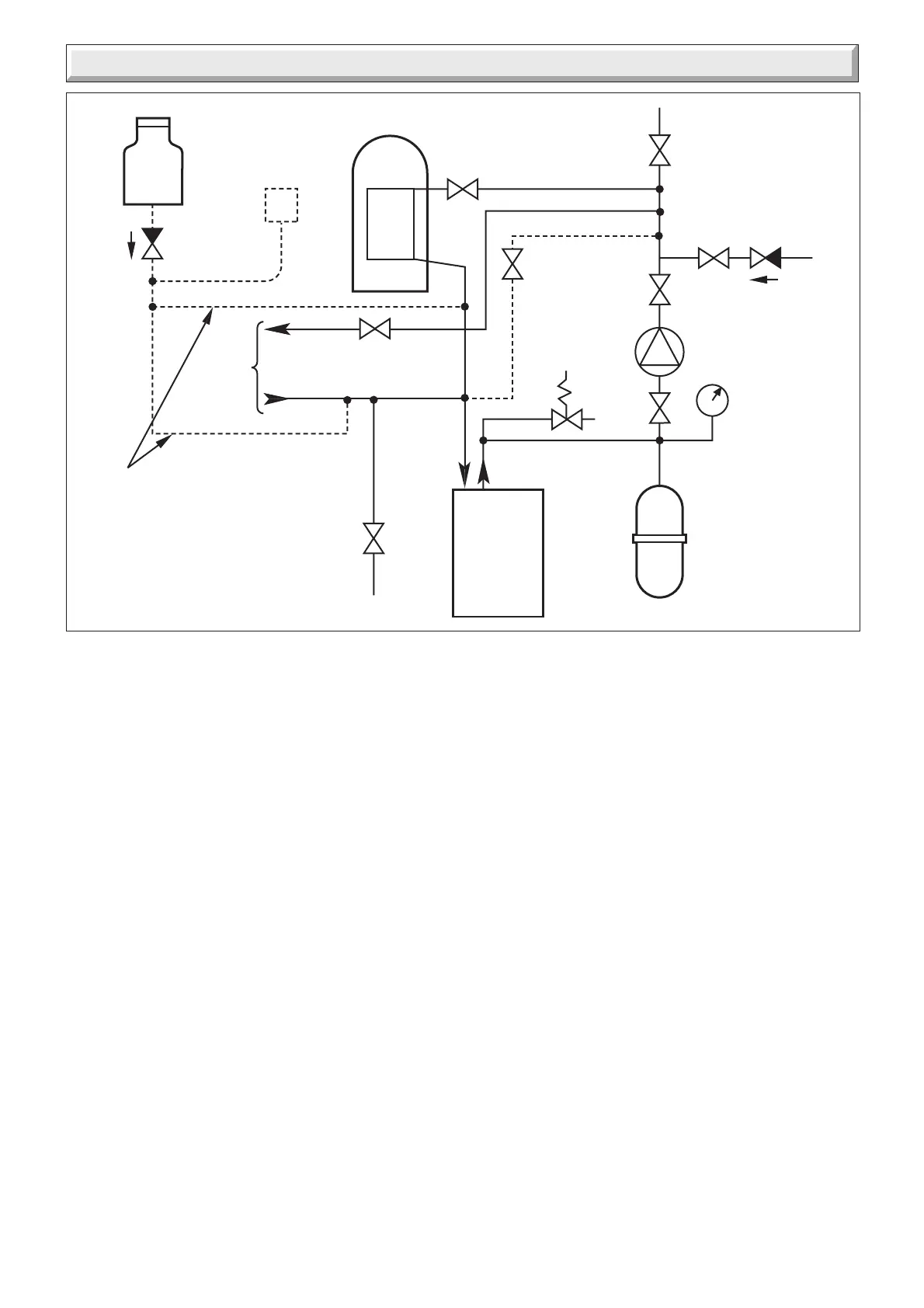

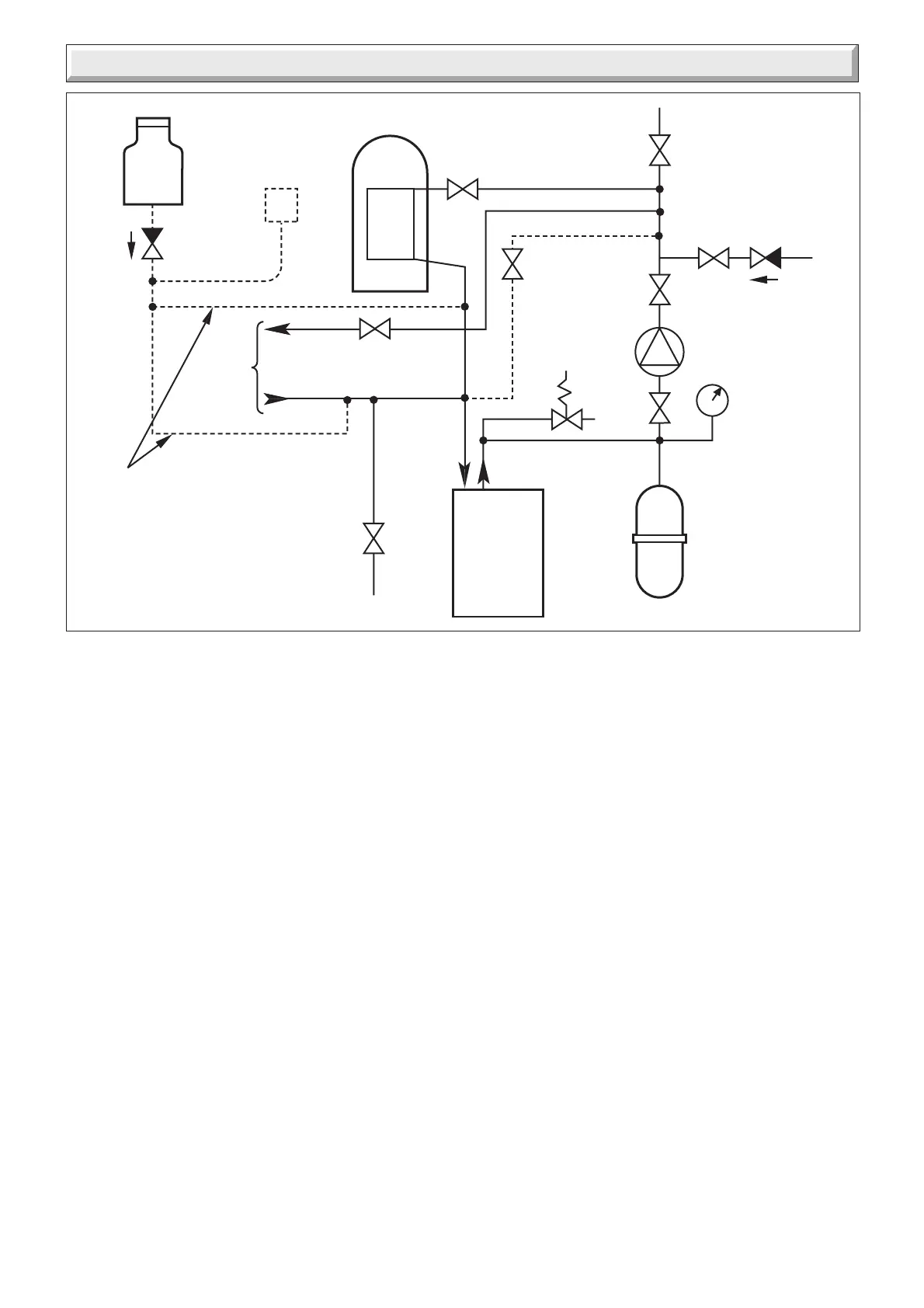

4 Water System

Diagram 4.3

9236

3 LITRES (0.66 gals)

MAKE-UP BOTTLE

(if required)

NON-RETURN

VALVE

AUTO

AIR

VENT

FLOW

DRAIN

COCK

BOILER

SAFETY

VALVE

(Make-up

alternatives)

EXPANSION

VESSEL

PRESSURE

GAUGE

CIRCULATING

PUMP

FILLING POINT

AIR

RELEASE

POINT

HEATING

CIRCUIT

BY-PASS

VALVE 'B'

IF REQUIRED

FLOW

CONTROL

VALVE 'A'

FLOW

CONTROL

VALVE 'A'

RETURN

4.5 Bypass

A bypass is not required on the central heating system unless

the system controls could allow the boiler and pump to operate

when there is no flow.

Where a bypass has to be fitted, the bypass must be placed at

least 1.5 metres away from the boiler.

4.6 Water Treatment

In the case of an existing installation, it is ESSENTIAL that prior

to installing the new boiler the system is thoroughly flushed. For

optimum performance after installation of a new system, the

boiler and its associated central heating system should also be

flushed. Flushing should be carried out in accordance with

BS7593: 1992 using a cleanser such as Sentinel X300 or X400,

or Fernox Superfloc.

For long-term corrosion protection, after flushing, an inhibitor

suitable for stainless steel exchangers should be used, refer to

the current issue of BS 5449 and BS 7593 on the use of

inhibitors in central heating systems. Examples are Sentinel

X100 and Fernox.

4.7 Open (Vented) Water System

The boiler must be supplied from an unrestricted water supply

taken from a feed and expansion cistern situated at a maximum

height of 27 metres (90ft) above the boiler.

The cold feed must be 15mm minimum size.

The vent must rise continuously and be unrestricted.

It is important that the relative positions of the pump, cold feed

and open vent are as shown in diagram 4.2.

4.8 Combined Feed and Vent

For combined feed and vent, a 22mm pipe must be fitted in

accordance with BS 5449.

4.9 Domestic Hot Water Cylinder

SINGLE FEED INDIRECT CYLINDERS ARE NOT SUITABLE

The domestic hot water cylinder must be of the double feed fully

indirect coil type.

Loading...

Loading...