17

0020008153A

4 Water System

4.1 Draining Tap

A draining tap must be provided at the lowest point of the

system, which will allow the entire system and hot water system

to be drained.

Draining taps shall be to the current issue of BS 2879.

4.2 Safety Valve

A safety valve need not be fitted to an open-vented system.

4.3 Pump

The pump should be fitted on the flow pipe from the boiler and

have isolating valves each side.

A variable duty pump should be set to give a temperature

difference of no greater than 20

0

C between the flow and return,

with the thermostat set at “MAX”, which is about 80

0

C, to give

a flow rate as shown in table 3.

See chart for pressure loss of the boiler, diagram 4.1.

High resistance microbore systems may require a higher duty

pump.

4.4 Flow Rate

If it is necessary to alter the flow rate, the system can be fitted

with a lockable balancing valve in the main flow or return pipes

shown as valve “A” in diagram 4.3. The flow rate through the

boiler must not be allowed to fall below that given in Table 3.

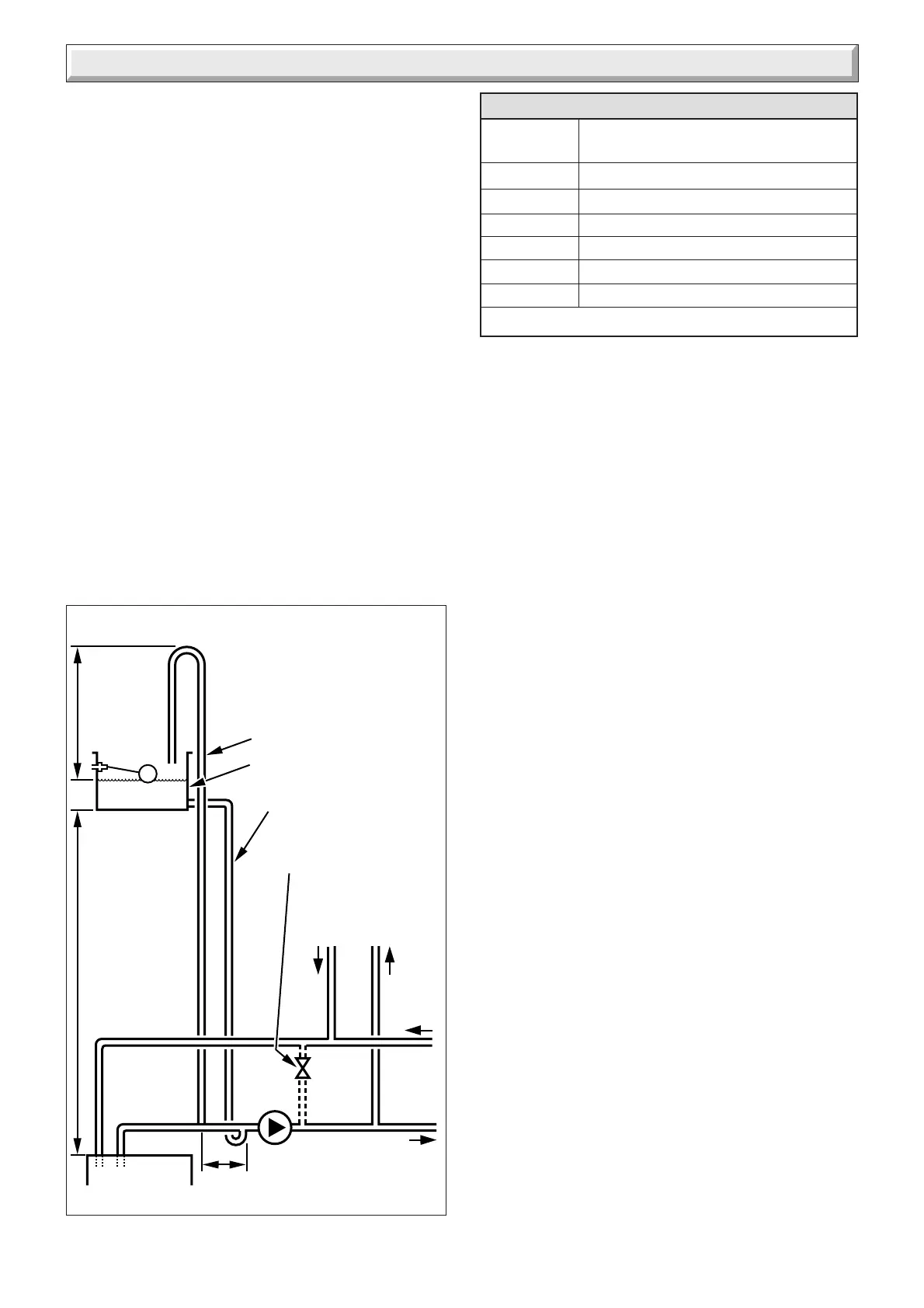

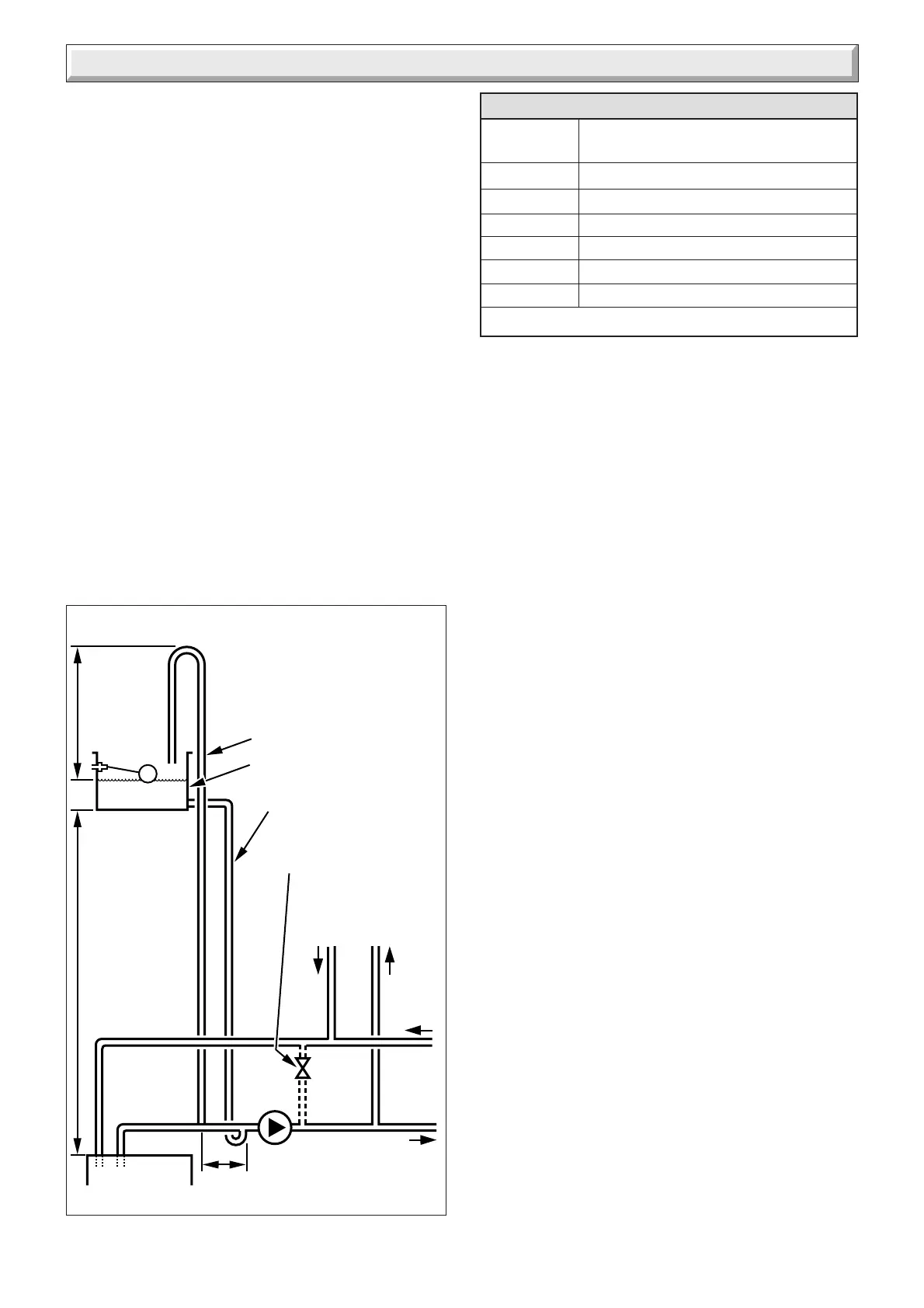

Diagram 4.2

9235

Open (vented) system.

Recommended

relationship between

pump, cold feed and vent.

22mm (MIN.) VENT

FEED AND

EXPANSION CISTERN

15mm (MIN) COLD FEED

15mm (MIN.) BY-PASS

WITH LOCKSHIELD

VALVE IF REQUIRED

RETURN

FLOW

HEATING

CYLINDER

PUMP

BOILER

150mm MAX.

1000mm

MIN.

450mm

MIN.

HEIGHT

Table 3. Flow Rate

MODEL MINIMUM FLOW RATE

12 hxi 520 litres/hr

15 hxi 646 litres/hr

18 hxi 773.8 litres/hr

24 hxi 500 litres/hr

30 hxi 1220 litres/hr

38 hxi 1633 litres/hr

This is equal to 20

o

C differential at maximum heat input.

Loading...

Loading...