25

221469B

11 Commissioning

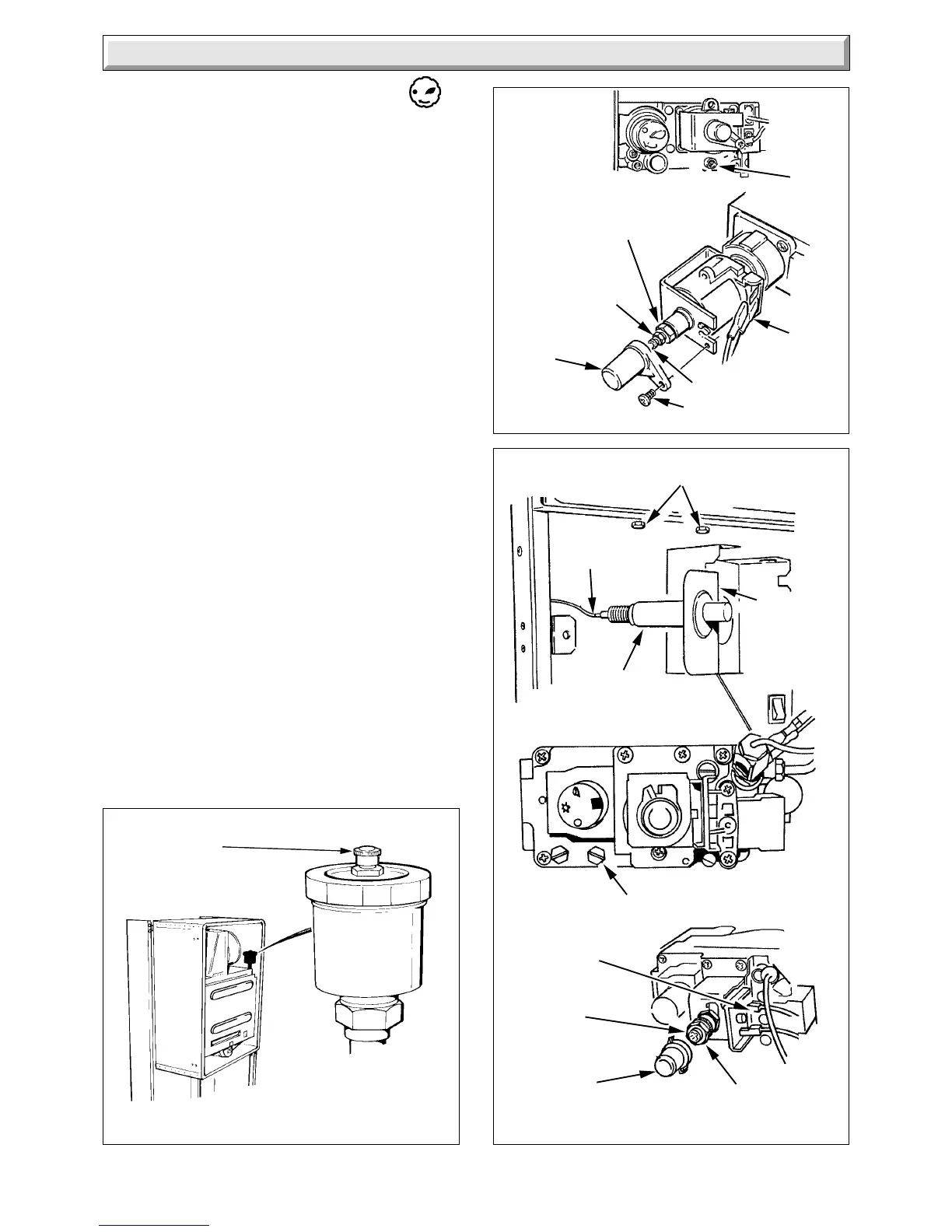

Diagram 11.3

SIT

Diagram 11.2

Diagram 11.3

HONEYWELL

SECURING SCREWS (2)

Slacken but do not remove

CAP

IGNITION

LEAD

PIEZO

UNIT

2932

CAP

SPINDLE

SMALL

ADJUSTMENT

NUT (MAX.

PRESSURE)

2344

AUTOMATIC AIR

VENT CAP

4447 S

TEST

POINT

LARGE

ADJUSTING

NUT (MIN.

PRESSURE)

ELECTRICAL

CONNECTOR

(GREY)

SCREW

PIEZO UNIT

BRACKET

Slide forward

and lower to

release from

keyhole fixing

ELECTRICAL

CONNECTOR

(GREY)

WHITE ADJUSTER

SCREW

(MIN PRESSURE)

LARGE ADJUSTING

NUT (MAX PRESSURE)

TEST

POINT

11.4 Initial Lighting of Pilot - Honeywell

Identify the boiler controls, see diagram 11.1.

Check that the boiler is isolated from the electrical supply at the

external isolator.

Fully depress and hold in gas control knob “D”.

Press and release piezo button “E” until the pilot burner lights,

(at this stage, air may be present in the gas components of the

boiler, therefore this operation may need to be repeated). When

the pilot flame has lit and is stable, keep knob “D” fully depressed

for 15 seconds, then release. The pilot burner should then

remain alight.

If the pilot flame goes out now or at any time, a safety device

prevents immediate relighting. Wait four minutes before

attempting to relight.

If the pilot burner goes out on releasing knob “D”, repeat the

above lighting sequence but this time keep knob “D” depressed

for a little longer.

The pilot flame size is preset and should envelop the

thermocouple, the approximate flame size is shown in diagram

11.4. If the flame size is incorrect refer to the adjusting

instructions in “Pilot Burner” in “Replacement of Parts” section

of the Servicing Instructions.

Check for gas soundness of the pilot supply using leak detection

fluid. Take care not to splash any of the electrical components.

Test the operation of the thermocouple flame failure system to

ensure the boiler shuts down within 60 seconds, indicated by a

“click” from the gas valve.

If the pilot burner will not stay alight, refer to “Thermocouple and

Overheat Cutoff” in “Fault Finding” section of the Servicing

Instructions.

Fit the cover of the inner case, making sure that it is fitted and

seals correctly, using the four screws previously removed, see

diagram 6.2.

Make sure that all hot water draw off taps are closed then set

switch “C” to “Off” as shown in diagram 11.1.

With the boiler isolated from the electrical supply the pilot flame

may go out. If this should happen, wait 4 minutes then relight

the pilot burner following the above lighting instructions but with

the electrical supply connected.

Loading...

Loading...