34

221469B

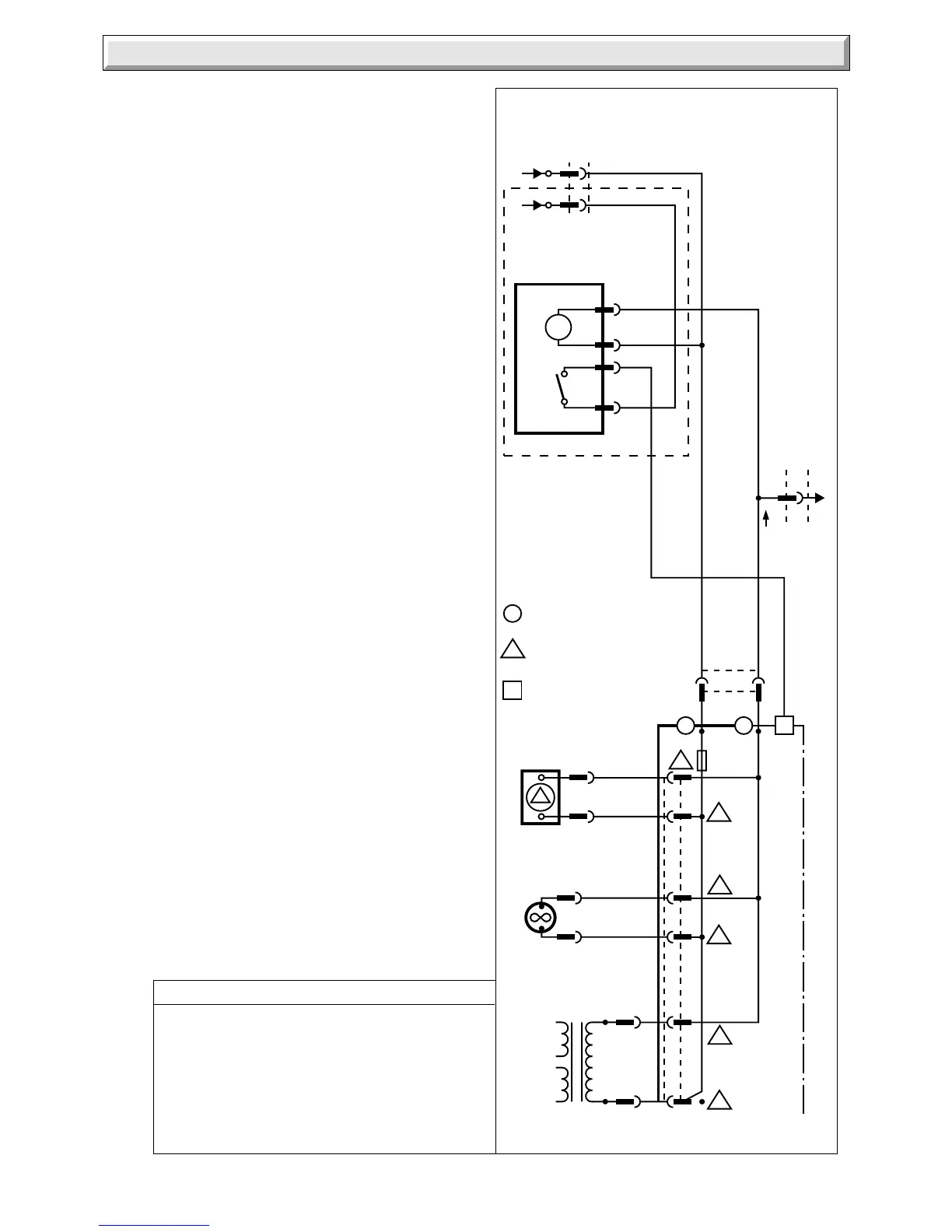

3 Fault Finding

(N)

br

b

LN

(L)

PERMANENT

LIVE

240V~50Hz

OPTIONAL

SWITCHED LIVE

FROM ROOM

STAT. 240V~50Hz

b

br

v

r

PUMP

FAN

TRANSFORMER

b

br

240V~

LOW

VOLT.

24V~

LOW

VOLT.

6V~

CONTROL BOARD

CONTROL BOARD

TERMINALS, BLOCK 3

CONTROL BOARD

TERMINALS, BLOCK 2

CONTROL BOARD

TERMINALS, BLOCK 6

T1-6A

FUSE 1

3

6

2

3 3

2

2

2

2

2

2

MAINS

FUNCTIONAL FLOW

KEY

BROWN........................br

BLUE............................b

RED..............................r

PURPLE.......................p

VIOLET.........................v

MAINS

FUNCTIONAL FLOW

M

COMMON

ON

(N)

(L)

CLOCK/TIMER

br

b

y

br

y

6

Diagram 3.5

5718

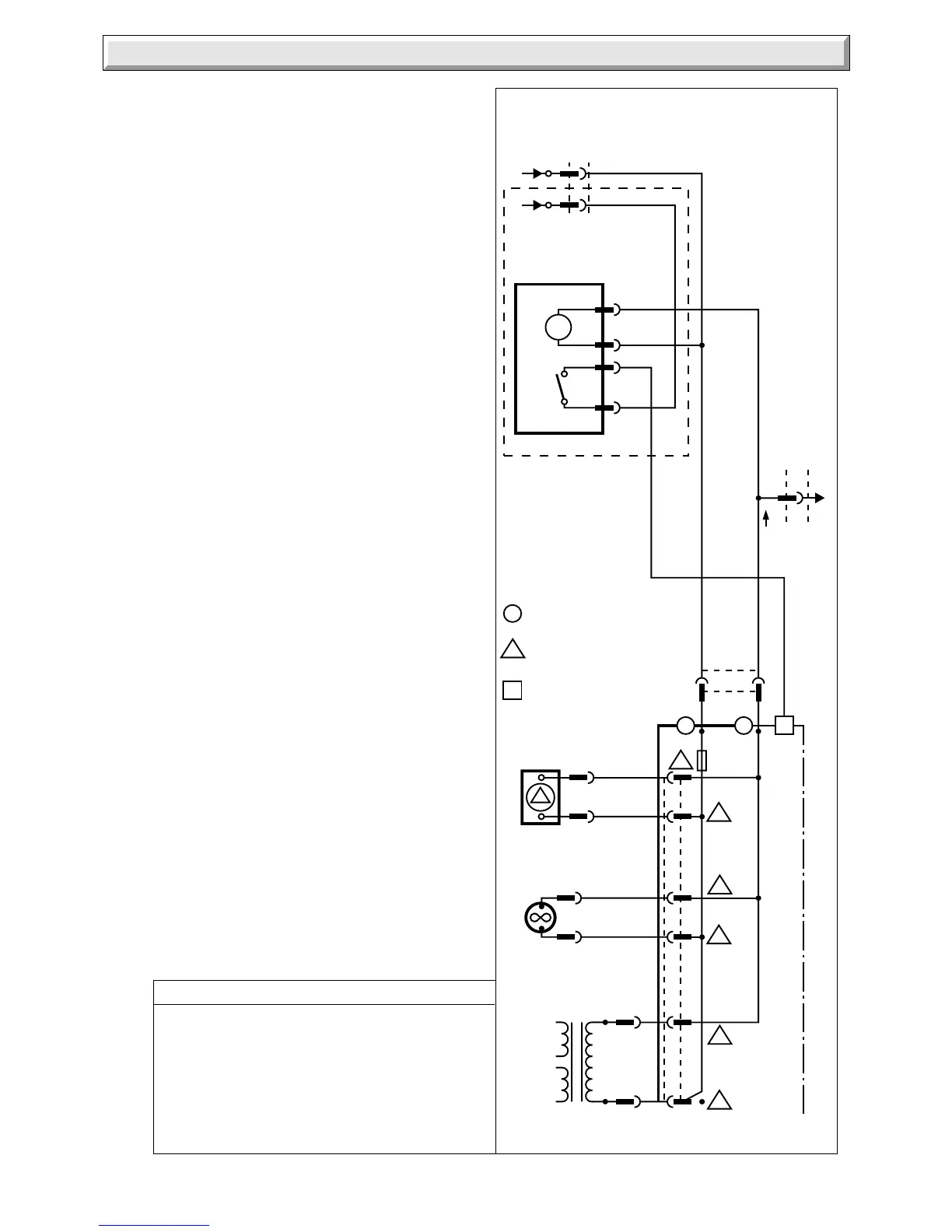

3.4 Clock/Timer

If the clock has failed it can be bypassed by disconnecting the

plug at the wall frame. Gain access to the control box, refer to

Section 4.12, disconnect the clock wiring harness from the four

way terminal block. Fit yellow link between terminals Y1 and

Y2.

This is a temporary measure and the clock should be repaired

or replaced as soon as possible.

3.5 Electrical

The preliminary electrical system checks, as described in a

multimeter test book, are the first checks to be carried out during

a fault finding procedure.

On completion of a fault finding task that has required the

disconnection and making of electrical connections, then checks

for earth continuity, polarity and resistance to earth must be

carried out.

Isolate the boiler from the electrical supply, refer to Section 1.3.

Gain access to the boiler controls by removing the outer case,

refer to Section 1.4. Check that all cables and connectors are

secure.

Gain access to the control board, refer to Section 4.13. Check

all cables at the multi-pin connectors on the board.

Test the two fuses on the control board and renew as necessary.

Fuse 1 is type T1.6A, fuse 2 type T 630mA. If a fuse repeatedly

fails or the initial fault finding checks, described in Section 3.1

indicate a boiler fault, check the boiler electrical circuits and

follow the fault finding procedures, see diagram 3.5, 3.6, 3.7 and

3.8, and for clock/timer fault finding diagram 3.9.

Loading...

Loading...