25

10.2 Horizontal Telescopic Flue

Refer to diagram 10.2 for kit contents.

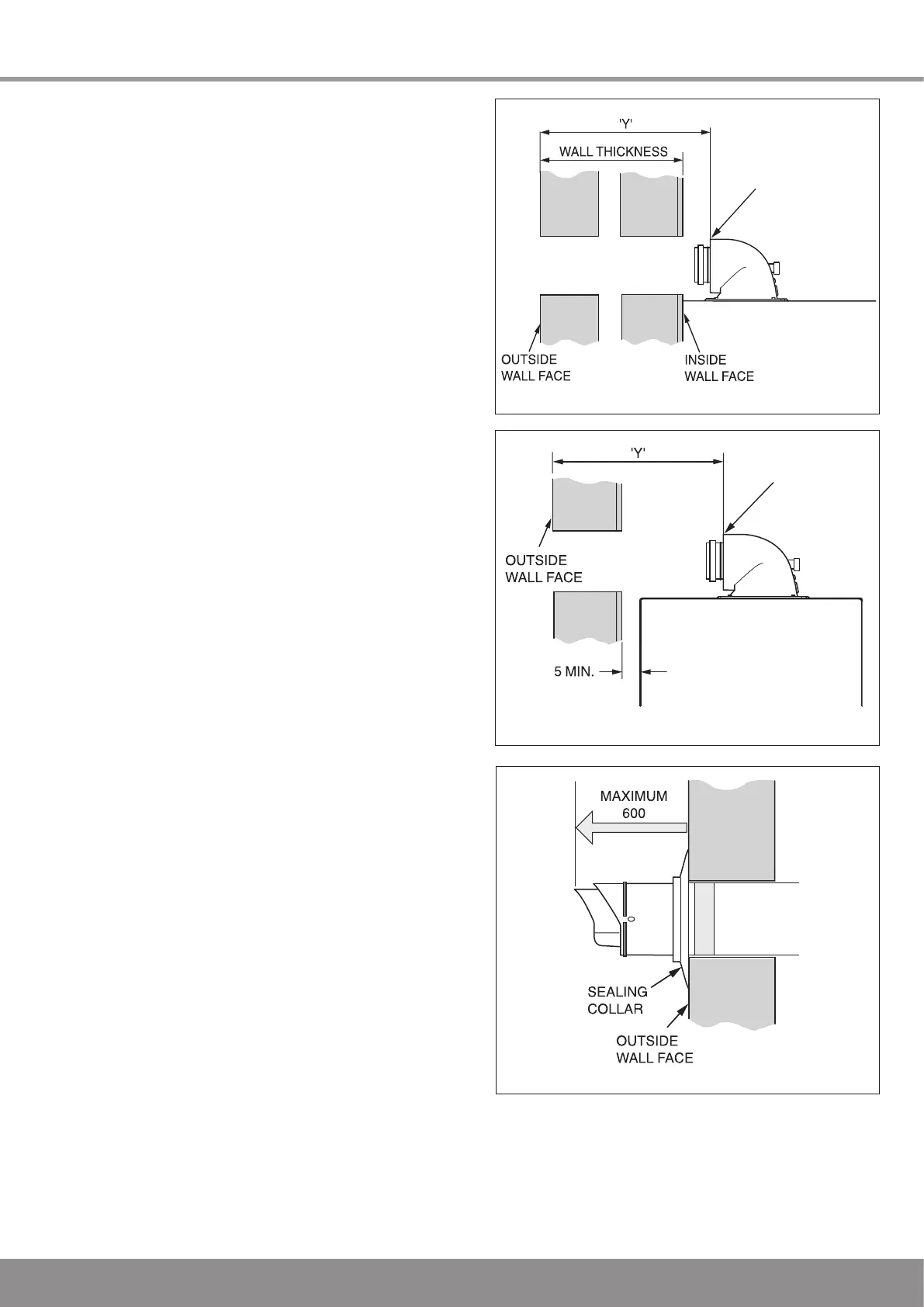

10.3 REAR Flue

If a wall thickness is between 233mm min. to 522mm max.

then the flue can be used without extensions.

With the flue elbow temporarily fitted, measure the distance

from the outside wall to the butt joint, see diagram

10.4. If

the measurement ‘Y’ exceeds 522mm, then the appropriate

length of extension pipe is required.

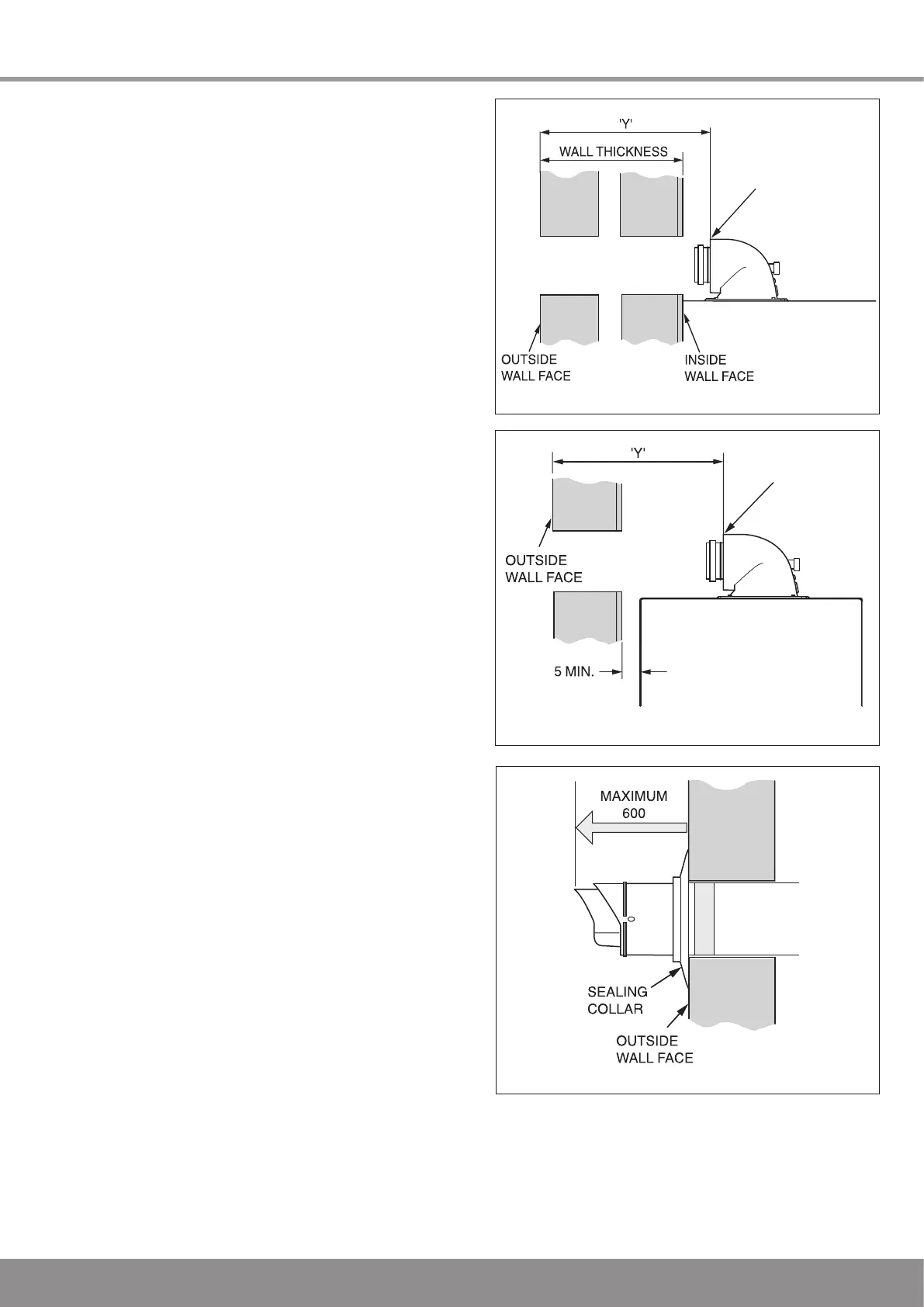

If the dimension is less than 320mm DO NOT cut the flue, it

can project to a maximum of 600mm, if this is not desirable

then a Standard flue MUST be used and cut to length.

10.4 SIDE Flue

With the flue elbow temporarily fitted, measure the distance

from the outside wall to the butt joint, see diagram 9.6. If the

measurement ‘Y’ exceeds LH 204mm, RH 417mm, then the

appropriate length of extension pipe is required.

If the dimension is less than 320mm DO NOT cut the flue, it

can project to a maximum of 600mm, if this is not desirable

then a Standard flue MUST be used and cut to length.

10.5 Flue Fitting

With the air duct seams aligned and the flue set to the

required length ‘Y’, mark the securing hole position in the air

duct. Drill a 3mm diameter hole at this position, take care not

to pierce the inner flue duct. Secure with screw provided and

tape the joint, see diagram 10.7.

Fit the sealing collar onto the locating ring on the flue

terminal, see diagram 10.8.

With the flue elbow removed, push the flue assembly into

the wall, externally or internally, until the end of the assembly

protrudes a short way from the inside face of the wall. This

will enable the internal trim ring (if required) to be positioned

and allow the flue assembly to be drawn back up to the flue

elbow.

Secure the flue elbow in position on top of the boiler with four

torque headed screws supplied.

Draw the flue assembly from wall and engage the flue duct

into the elbow and butt fit between the air duct and flue

elbow.

Check the correct alignment of the flue.

Fit the securing collar in position, mark through two of the pre

drilled holes in the securing collar. Remove securing collar

and drill two 3mm diameter holes one in the elbow and one

in the air duct, take care not to pierce the inner flue duct. Fit

the securing collar and secure with screws provided, see

diagram 10.9.

Slide the internal trim ring back against the wall, securing in

place with a small amount of sealant if required.

The cut ducts must be de-burred and all filings and debris

removed.

Insert the flue duct into the air duct terminal assembly,

remembering to engage the catch within the terminal.

NOTE: If the seals require lubricant to ease installation, do

not use mineral oils or grease, only silicon grease or water is

recommended.

Diagram 10.4

Diagram 10.6

12979

10 Telescopic Flue - Length, Preparation and Installation

Diagram 10.5

13224

13295

Loading...

Loading...