47

13 Servicing

13.7 Heat Exchanger

NOTE: If the functional checks did not indicate poor

combustion then it is not necessary to service the heat

exchanger.

Refer to diagram 13.11.

Remove loose debris from inside the heat exchanger using a

soft brush and vacuum cleaner.

Carefully flush by spraying water into the heat exchanger, any

remaining debris should pass through the condensate trap

(Ensure the water is kept away from electrical components).

13.8 Combustion Setting

A combustion check should not be necessary unless a gas

carrying component has been replaced or the combustion

setting is suspect.

Connect a flue gas analyser to the sampling point, see

diagram 13.13.

IMPORTANT: Products of combustion will be discharged

when the cap is removed. It is important to replace the cap

immediately.

If no flue gas analyser is available and with the boiler module

front panel removed, check the flame picture through the

viewing window

Turn on the gas service cock, see diagram 12.1.

Turn on the electrical supply, the appliance will begin the

ignition sequence.

A competent person only should carry out any adjustment

to the gas valve, refer to diagram 13.14.

Monitor the combustion reading and at max rate the reading

should be 9.2% ± 0.5.

If adjustment proves necessary then proceed as follows:

Press the “reset” button on the controls fascia, release

and immediately press and hold in the “+” button. After

approximately 5 seconds “Hi” will be displayed.

Pressing the mode button when “Hi” is selected will force the

boiler to maximum rate, the display will flash between “Hi”

and the “default display” this will indicate the boiler has been

forced to maximum.

Adjust the maximum rate CO

2

with the throttle to 9.2%.

(Rotate anti-clockwise to increase).

To exit the check sequences press the “+” button, this will

reset the boiler to the default display.

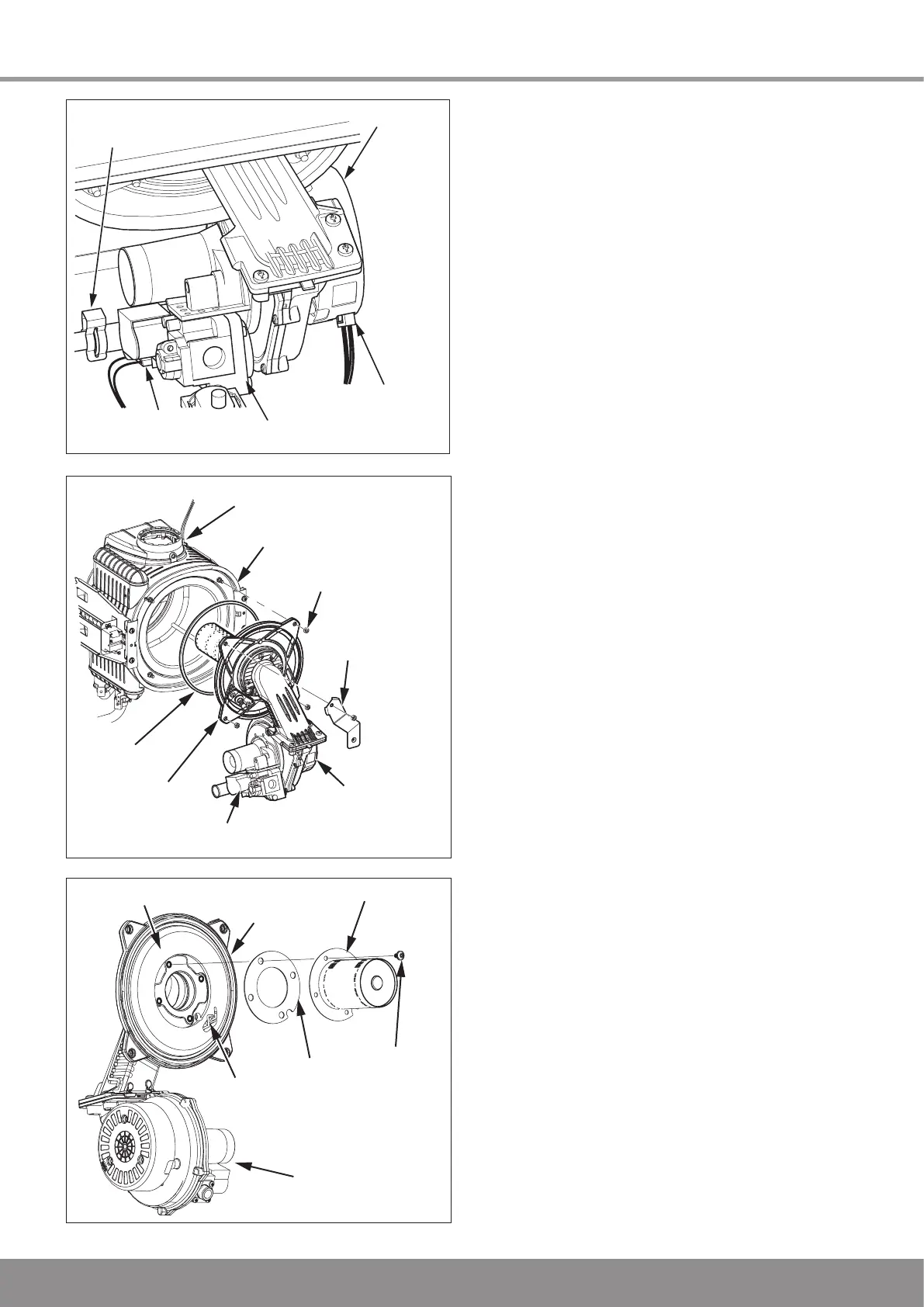

ELECTRICAL

CONNECTION

GAS VALVE

FAN

ELECTRICAL

CONNECTION

GAS SUPPLY PIPE

SECURING CLIP

Diagram 13.10

13350 13356

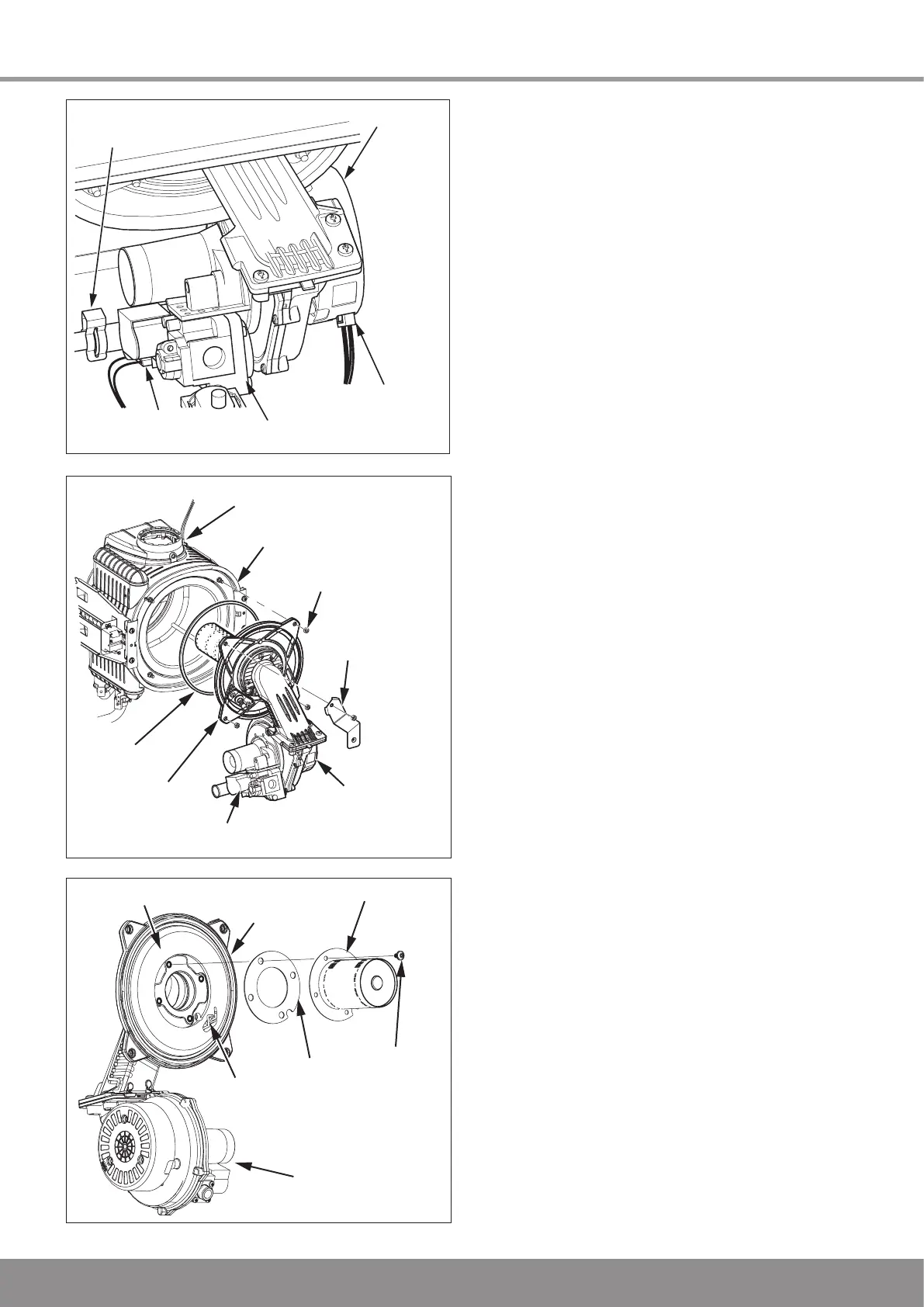

BURNER

FRONT INSULATION

GASKET

SECURING

SCREW (4)

SPARK

ELECTRODE

GAS VALVE

AND FAN

BURNER

DOOR

Diagram 13.12

13373

NYLOC

NUT (4 OFF)

GAS VALVE

FA

N

BURNER

DOOR

SILENCER

BRACKET

SEAL

HEAT EXCHANGER

FLUE

OVERHEAT THERMOSTAT

Diagram 13.11

Loading...

Loading...