46

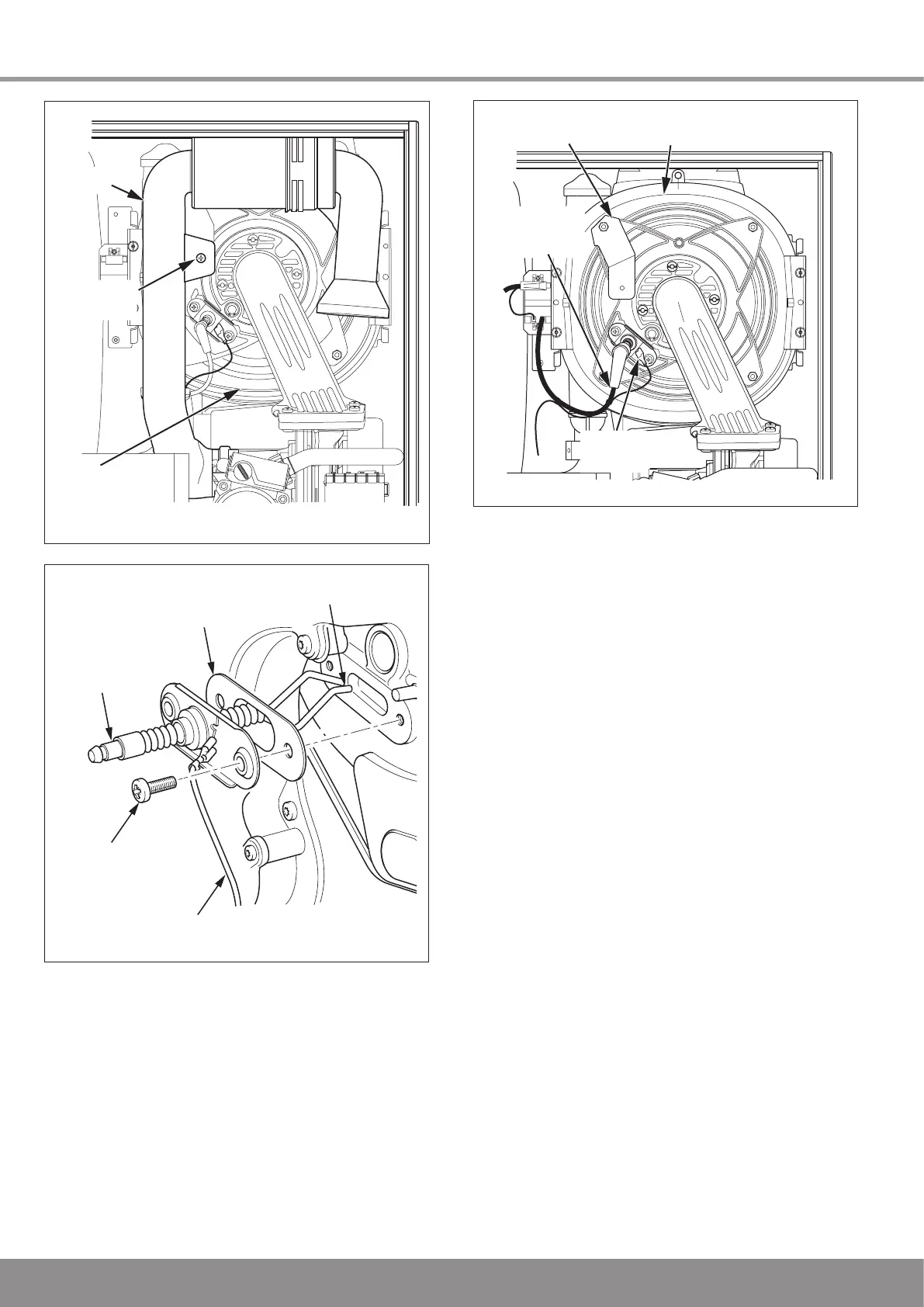

SECURING

SCREW

HEAT

EXCHANGER

SILENCER

13.6 Burner

NOTE: If the functional checks did not indicate poor

combustion then it is not necessary to service the burner.

The following procedure will require that you replace the

burner door seal and nyloc nuts.

Slacken the gas connection at the union nut between the

boiler module and tank module.

Remove the gas supply pipe securing clip and withdraw the

gas pipe from gas valve, see diagram 13.10.

Disconnect the electrical connection at the gas valve and

disconnect the electrical connection from the fan.

Disconnect the ignition lead and earth lead from the burner

door, see diagram 13.9.

Disconnect the flue overheat thermostat, see diagram 13.11.

Remove the four burner door nyloc nuts, one of these also

holds the silencer bracket, see diagram 13.11.

Gently remove the fan, gas valve and burner assembly from

the combustion chamber, taking care not to trap the primary

return thermistor electrical cables.

Clean the burner with a soft brush taking great care not to

damage the front insulation. DO NOT use wire or sharp

instruments to clean the holes of the burner. Inspect the

burner for any signs of damage.

Remove and discard the burner door seal and replace with

new.

NOTE: Removal of the burner is not necessary during a

normal service, but If the burner has to be removed it will

require a new gasket when refitted, see diagram 13.12.

13343

Diagram 13.7

13 Servicing

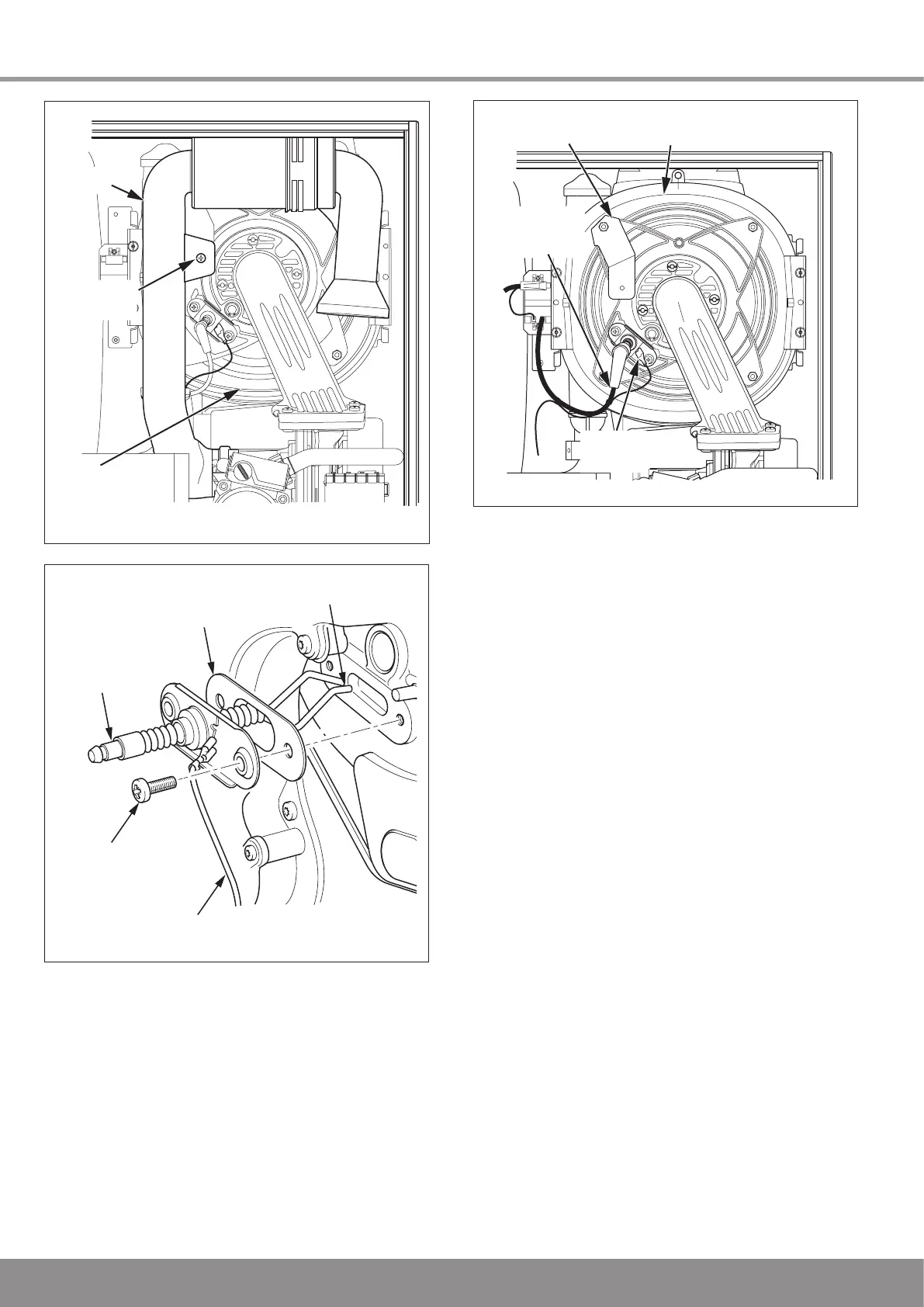

ELECTRODE

GASKET

SPARK GAP

4mm

SECURING

SCREW

(2 OFF)

EARTH

LEAD

13273

Diagram 13.8

Diagram 13.9

13346

SILENCER

BRACKET

EARTH

LEAD

IGNITION

LEAD

HEAT

EXCHANGER

Loading...

Loading...