7

D5290 - 10 A SIL 3 Relay Output Module for NE Load G.M. International ISM0111-8

The proof test shall be performed to reveal dangerous faults which are undetected by diagnostic. This means that it is necessary to specify how dangerous undetected faults, which

have been noted during the FMEDA, can be revealed during proof test. The Proof test consists of the following steps:

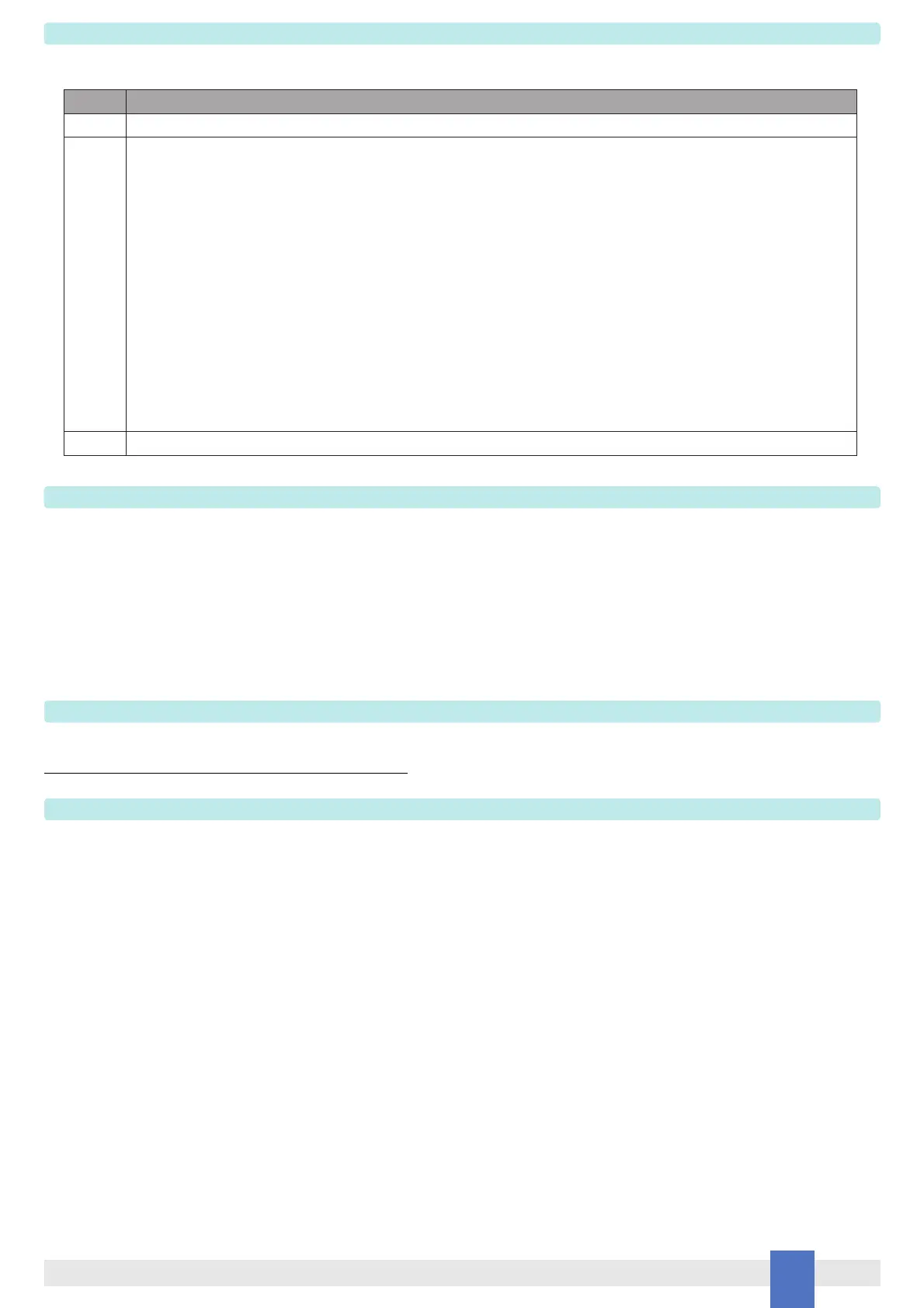

Testing procedure at T-proof

Steps Action

1 Bypass the safety-related PLC or take other appropriate action to avoid a false trip when removing the unit for test.

2 For the single channel, verify the input-to-output functionality:

the output load is normally energized by supplying the input channel, while shutdown of the input channel de-energizes the load (safe state).

The channel functionality must be verified for a min to max input voltage change (21.6 to 27.6 Vdc).

In addition, the use of three relays for the single output channel, where the contacts are connected in series, requires to control the single coil by means of

DIP-switches (n°1, 3, 5) and to check the ohmic continuity of the contacts, as described in the following procedure.

1. Do not supply the input channel (terminals “1”-“2” or “3”-“4”) of the unit under test and verify that the ohmic continuity at the Out 1 and Out 2 contacts

(terminals “13”-“21” and “14”-“22”) is absent (i.e. both the Out 1 contact (series connection of two relay contacts) and the Out 2 contact are open:

1

st

requisite is verified). For Out 1 contact, this condition could also be true if only one of two relay contacts in series is open and other is blocked

(for welding) into closed or open position: this will be verified by testing the channel when input is supplied, as described in the point 3 of the procedure.

Instead, the presence of ohmic continuity at the Out 1 implies that both relay contacts in series are blocked (for welding) into closed position, while

the presence of ohmic continuity at the Out 2 implies that the relay contact is blocked (for welding) into closed position.

2. Supply the input channel (terminals “1”-“2” or “3”-“4”) of the unit under test and verify that the ohmic continuity at the Out 1 and Out 2 contacts (terminals

“13”-“21” and “14”-“22”) is present (i.e. both the Out 1 contact (series connection of two relay contacts) and the Out 2 contact are closed: 2

nd

requisite is

verified). The absence of ohmic continuity at the Out 1 contact implies that one of two relay contacts in series is blocked (for welding) into open position:

this could only be verified disassembling and individually testing each of two relay contacts. Instead, the absence of ohmic continuity at the Out 2 contact

implies this relay contact is blocked (for welding) into open position.

3. Always supplying the input channel (terminals “1”-“2” or “3”-“4”) of the unit under test, to verify if one of two relay contacts in series (Out 1) is blocked

(for welding) into closed position, use internal DIP-switches (n°1 and 3) to put in short circuit one relay coil at a time (starting with the 1

st

coil by

DIP-switch n°1, then going on with the 2

nd

one by DIP-switch n°3), verifying that the ohmic continuity is always absent between terminals “13”-“21”.

The presence of ohmic continuity implies that a relay contact (the only one with de-energized coil) is blocked (for welding) into closed position.

3 Remove the bypass from the safety-related PLC or restore normal operation inserting the unit.

This test reveals almost 99 % of all possible Dangerous Undetected failures in the relay module.

Warning

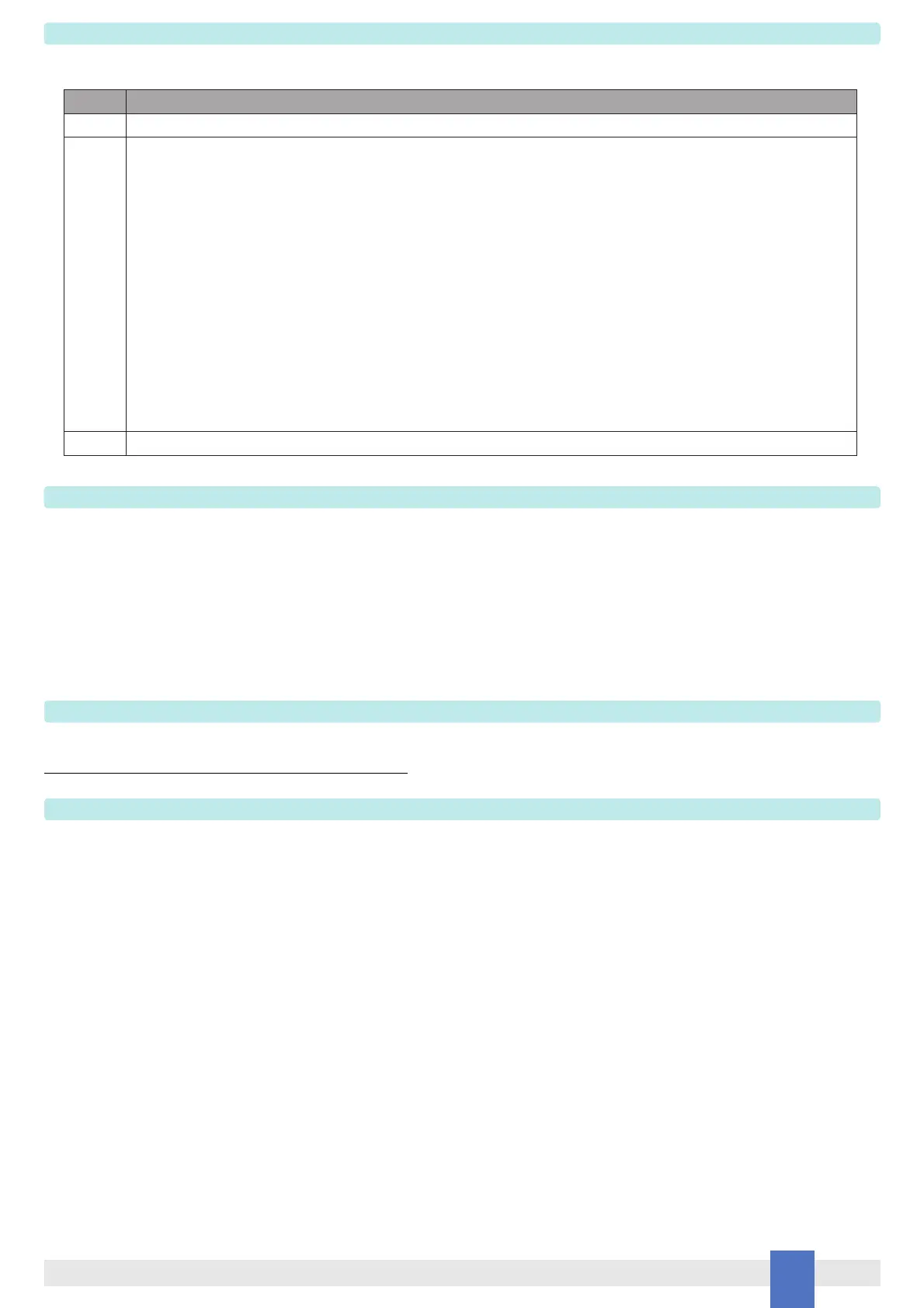

Operation

D5290S relay module is suitable for the switching of safety related circuits, providing isolation between the input and output contacts.

D5290S provides two NO contacts for normally energized load and a NC contact for service purpose, in order to switch the NE load on both supply lines.

See the previous pages for Functional Safety applications with related SIL value.

A “RELAY STATUS” yellow led lights when input is powered, showing that relay is energized.

Installation

D5290S is a relay output module housed in a plastic enclosure suitable for installation on T35 DIN-Rail according to EN50022 or on customized Termination Board.

D5290S unit can be mounted with any orientation over the entire ambient temperature range.

Electrical connection of conductors up to 2.5 mm² are accommodated by polarized plug-in removable screw terminal blocks which can be plugged in/out into a powered unit without

suffering or causing any damage (for Zone 2 installations check the area to be nonhazardous before servicing).

The wiring cables have to be proportionate in base to the current and the length of the cable.

On the section “Function Diagram” and enclosure side a block diagram identifies all connections.

Identify the function and location of each connection terminal using the wiring diagram on the corresponding section, as an example (interruption of both NE load supply lines):

Connect positive input at terminal “1” and negative input at “2” (positive input at terminal “3” and negative input at “4” are provided for daisy chain connection to the next module).

Connect positive or AC load supply line to CM1 Common pole (terminal “13” (for SIL 3 NE load and Not SIL Service Load)).

Connect SIL 3 Normally Energized (NE) Load at terminal “21” and “22”.

Connect negative or AC load supply line at terminal “14” (for SIL 3 NE load).

Connect Not SIL Service Load at terminal “15” and to negative or AC load supply line.

Installation and wiring must be in accordance to the relevant national or international installation standards (e.g. IEC/EN60079-14 Electrical apparatus for explosive gas atmospheres

Part 14: Electrical installations in hazardous areas (other than mines)), make sure that conductors are well isolated from each other and do not produce any unintentional connection.

Connect SPST relay contacts checking the load rating to be within the contact maximum rating (10 A 250 Vac 2500 VA, 10 A 250 Vdc 300 W resistive load).

To prevent relay contacts from damaging, connect an external protection (fuse or similar), chosen according to the relay breaking capacity diagram on data sheet.

The enclosure provides, according to EN60529, an IP20 minimum degree of mechanical protection (or similar to NEMA Standard 250 type 1) for indoor installation, outdoor installation

requires an additional enclosure with higher degree of protection (i.e. IP54 to IP65 or NEMA type 12-13) consistent with the effective operating environment of the specific installation.

Units must be protected against dirt, dust, extreme mechanical (e.g. vibration, impact and shock) and thermal stress, and casual contacts.

If enclosure needs to be cleaned use only a cloth lightly moistened by a mixture of detergent in water.

Electrostatic Hazard: to avoid electrostatic hazard, the enclosure of D5290S must be cleaned only with a damp or antistatic cloth.

Any penetration of cleaning liquid must be avoided to prevent damage to the unit. Any unauthorized card modification must be avoided.

Relay output contact must be connected to load non exceeding category II overvoltage limits.

Warning: de-energize main power source (turn off power supply voltage) and disconnect plug-in terminal blocks before opening the enclosure to avoid electrical shock

when connected to live hazardous potential.

D5290S is an electrical apparatus installed into standard EN50022 T35 DIN-Rail located in Safe Area or Zone 2, Group IIC, Temperature Classification T4, Hazardous Area

(according to EN/IEC60079-15) within the specified operating temperature limits Tamb - 40 to +60 °C.

D5290S must be installed, operated and maintained only by qualified personnel, in accordance to the relevant national/international installation standards (e.g. IEC/EN60079-14

Electrical apparatus for explosive gas atmospheres - Part 14: Electrical installations in hazardous areas (other than mines)), following the established installation rules.

De-energize power source (turn off power supply voltage) before plug or unplug the terminal blocks when installed in Hazardous Area or unless area is known to be nonhazardous.

Warning: substitution of components may impair Intrinsic Safety and suitability for Zone 2.

Warning: de-energize main power source (turn off power supply voltage) and disconnect plug-in terminal blocks before opening the enclosure to avoid electrical shock

when connected to live hazardous potential.

Explosion Hazard: to prevent ignition of flammable or combustible atmospheres, disconnect power before servicing or unless area is known to be nonhazardous.

Failure to properly installation or use of the equipment may risk to damage the unit or severe personal injury.

The unit cannot be repaired by the end user and must be returned to the manufacturer or his authorized representative.

Any unauthorized modification must be avoided.

Loading...

Loading...