8

D5290 - 10 A SIL 3 Relay Output Module for NE Load G.M. International ISM0111-8

Start-up

Before powering the inputs of unit check that all wires are properly connected, also verifying their polarity. Check conductors for exposed wires that could touch each other causing

dangerous unwanted shorts. Enabling input, the “RELAY STATUS” yellow led must be lit and load circuit must be energized because relay output contacts (Out 1 and Out 2) are closed.

Indeed, disabling input, the “RELAY STATUS” yellow led must be turned off and load circuit must be de-energized because relay output contacts (Out 1 and Out 2) are open.

Configuration

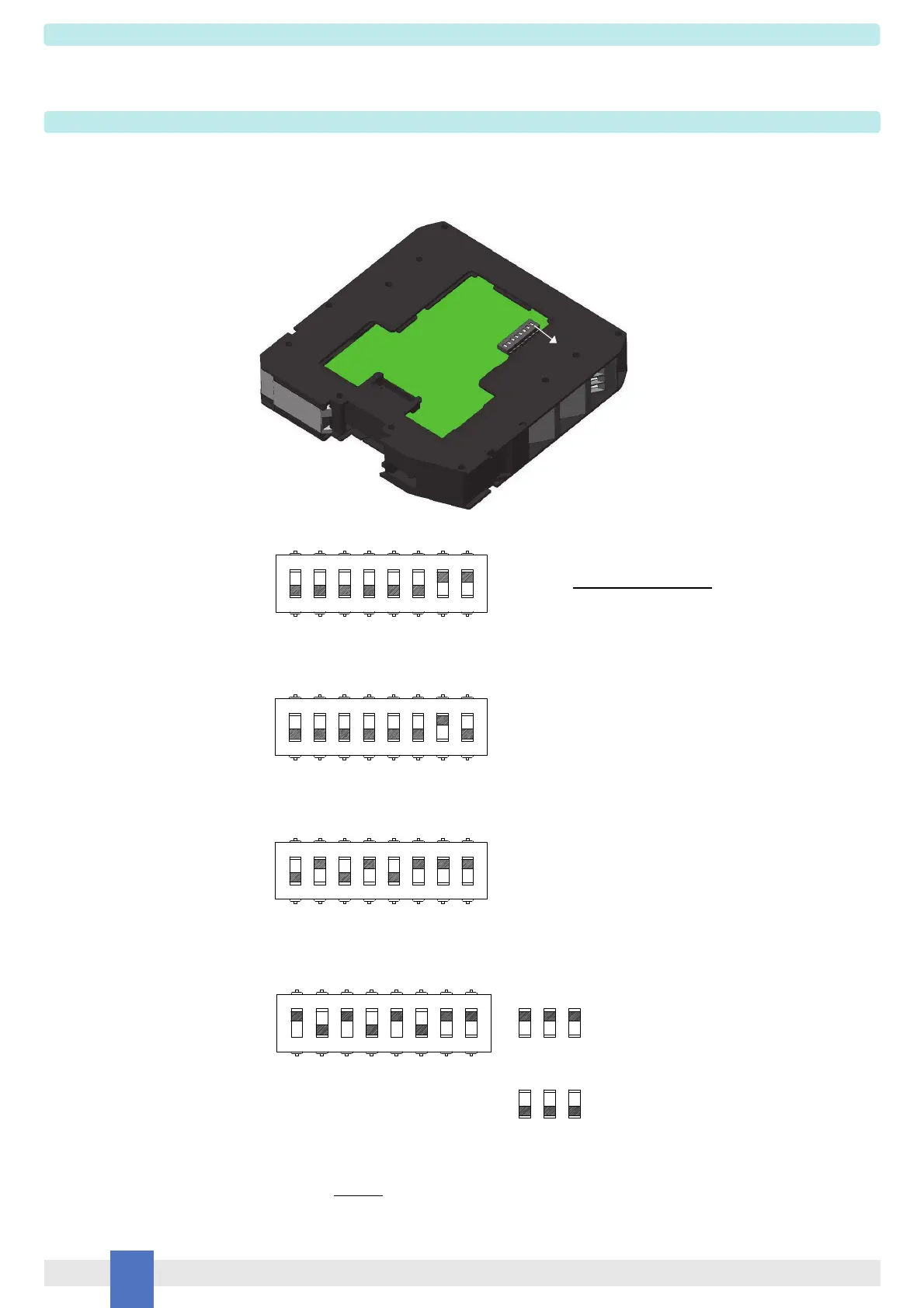

An eight position DIP Switch is located on component side of pcb in order to set four mutually exclusive configurations:

1) line input monitoring, to allow DCS/PLC line input monitoring function (driving line pulse testing);

2) low voltage input monitoring (UVLO—under voltage lock out): module reflects a high impedance state to the control unit when the driving voltage is below the specified threshold;

3) short circuit fault detection: it allows DCS/PLC to detect short circuit fault of module;

4) T-proof relay testing.

ON

1) line input monitoring:

2) low voltage input monitoring:

3) short circuit fault detection:

4) T-proof relay testing:

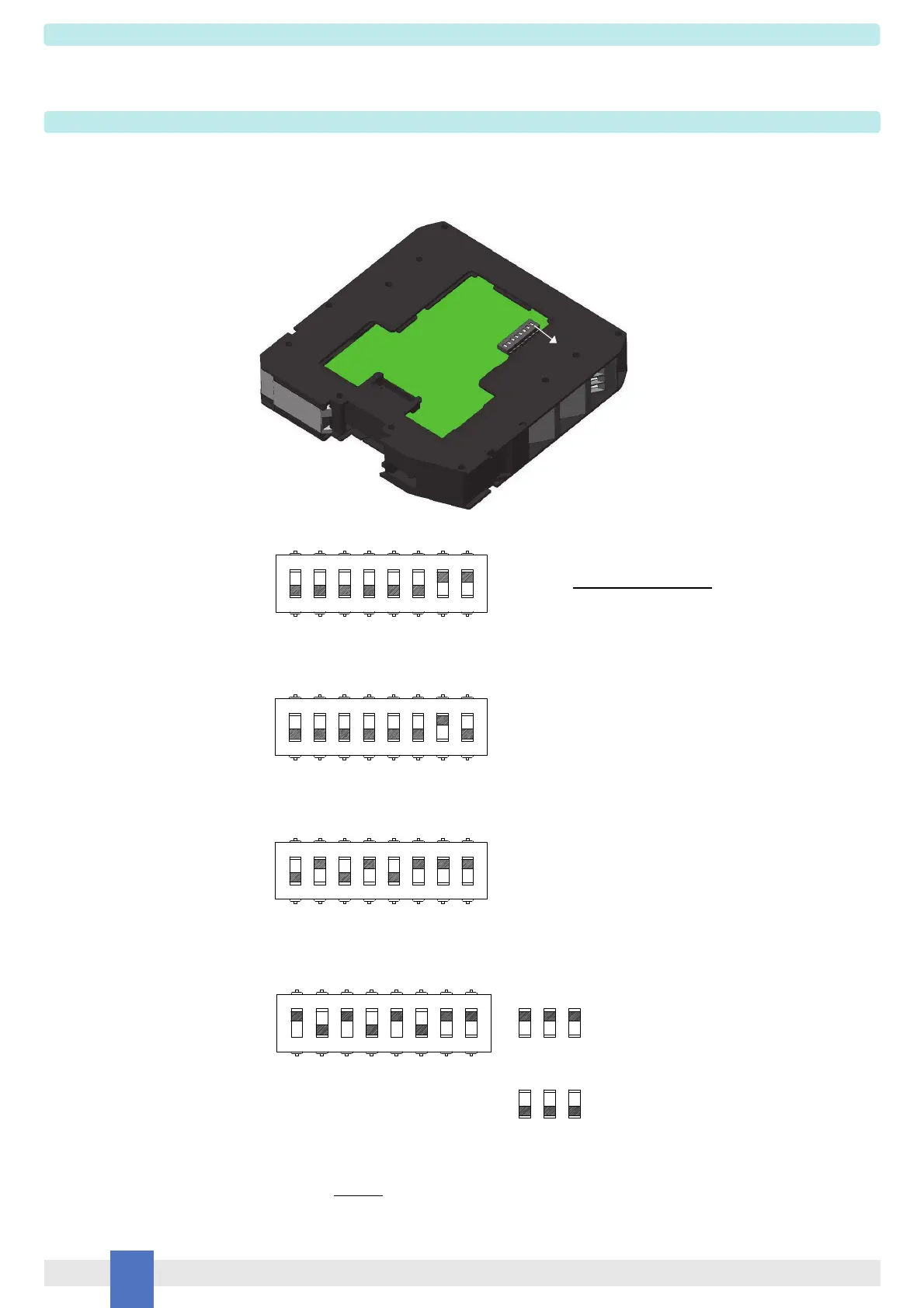

DIP switch configurations:

123

45

6

7

8

ON

OFF OFF OFF OFF OFF OFF ON ON

12345678

ON

OFF OFF OFF OFF OFF OFF ON OFF

123

45

6

7

8

ON

OFF ON OFF ON OFF ON ON ON

T-proof relays enable

135

13

5

Normal Operation

ON ON

OFF

ON

OFFOFF

T-proof relays (dip1 = relay1;

dip3 = relay2; dip5 = relay3)

12345678

ON

ON OFF ON OFF ON OFF ON ON

Please, see next page for testing procedure at T-proof.

WARNING: after T-proof test, dip-switch 1-3-5 must be set to “OFF” position for normal operation.

This is factory settings

Loading...

Loading...