Installation

308655K 7

Grounding

Follow local electrical code for detailed grounding

instructions.

Pump:

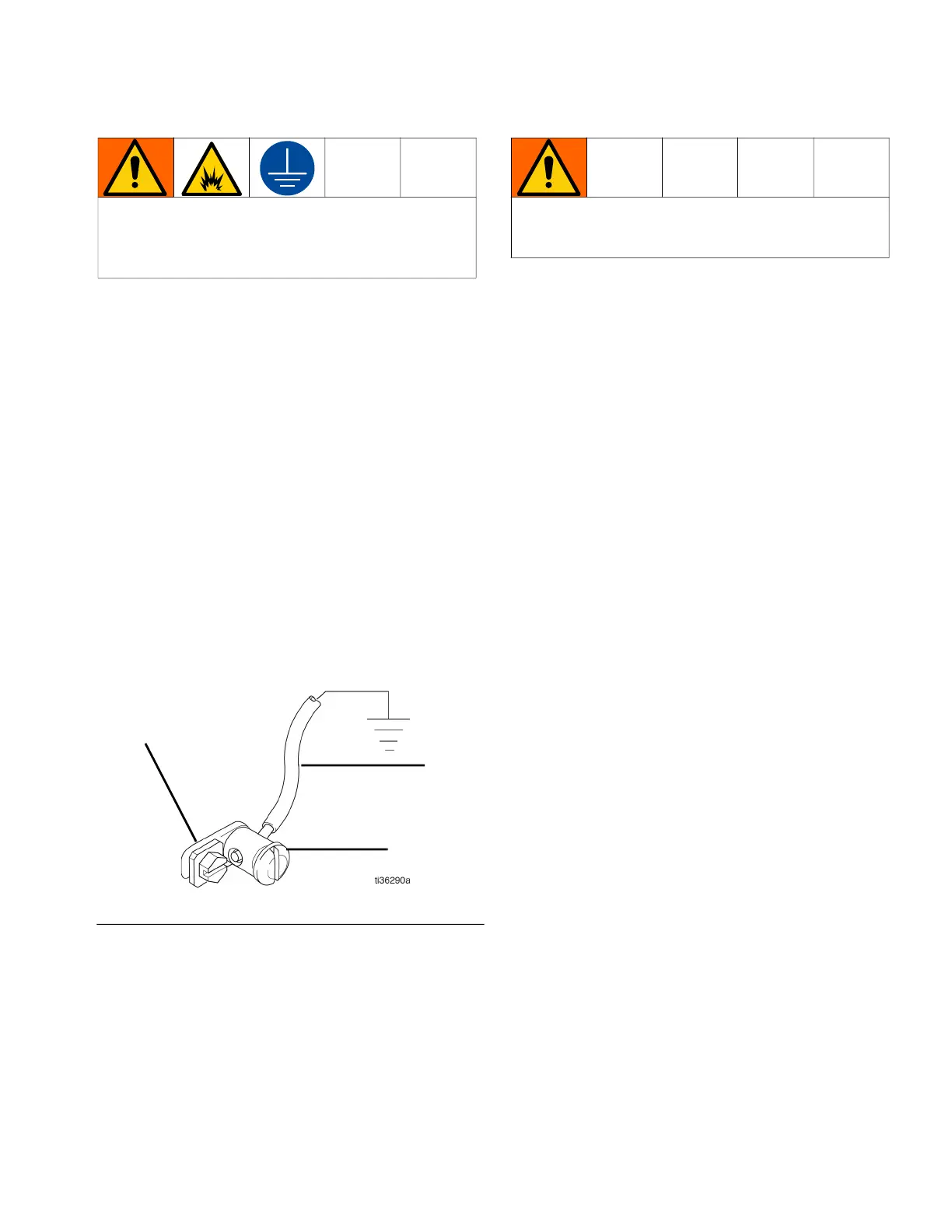

Refer to F

IG. 2 for the following instructions.

1. Remove the ground screw (Z) located on the side of

the pump base.

2. Insert the ground screw (Z) through the eye of the

ring terminal (W) located at the end of the ground

wire (Y).

3. Fasten the ground screw (Z) back onto the back of

the pump and tighten the screw securely.

4. Connect the other end of the ground wire (Y) to a

true earth ground. To order a ground wire and

clamp, order Part No. 222011.

Air and fluid hoses: use only electrically conductive

hoses.

Air compressor: follow manufacturer’s

recommendations.

Fluid supply container: follow local code.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

Mounting

Install the pump in a location that adequately supports

the weight of the pump when filled with lubricant and

also provides easy operator access to the pump air

controls. The pump must be mounted in a vertical posi-

tion. See Technical Specifications, page 20 for pump

weight information and the Dimensions and Mounting

Hole Layout, page 19.

Cover Mount

Pump Model 222065 is designed for mounting directly

onto a 55-gallon drum cover. When the pump is

mounted to a closed-head drum, loosen the vent plug

on the drum cover to prevent a vacuum in the drum. For

cover mounting, see the Mounting Hole Layout,

page 19.

Wall Mount

The pump shown in FIG. 1 is a wall mounted universal

pump, Model 205626. To oder the wall mounting

bracket, order Part No. 238425.

Bung Mount

Pump model 222095 is designed for bung mounting on

a 55-gallon drum. The bung adapter (153) is shown in

Parts, page 16.

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes

to ignite or explode. Grounding provides an escape

wire for the electric current.

FIG. 2

Z

W

Y

Mount the pump securely so that it cannot move

around during operation. Failure to do so could result

in injury or equipment damage.

Loading...

Loading...