Troubleshooting

308608L 11

Troubleshooting

1. Follow Pressure Relief Procedure, page 8, before

checking or repairing the pump.

2. Check all possible problems and causes before

disassembling pump.

*Follow the Pressure Relief Procedure, page 8, then disconnect the fluid line. If the pump starts when the air is

turned on again, there is a clog in the line, hose, valve, etc.

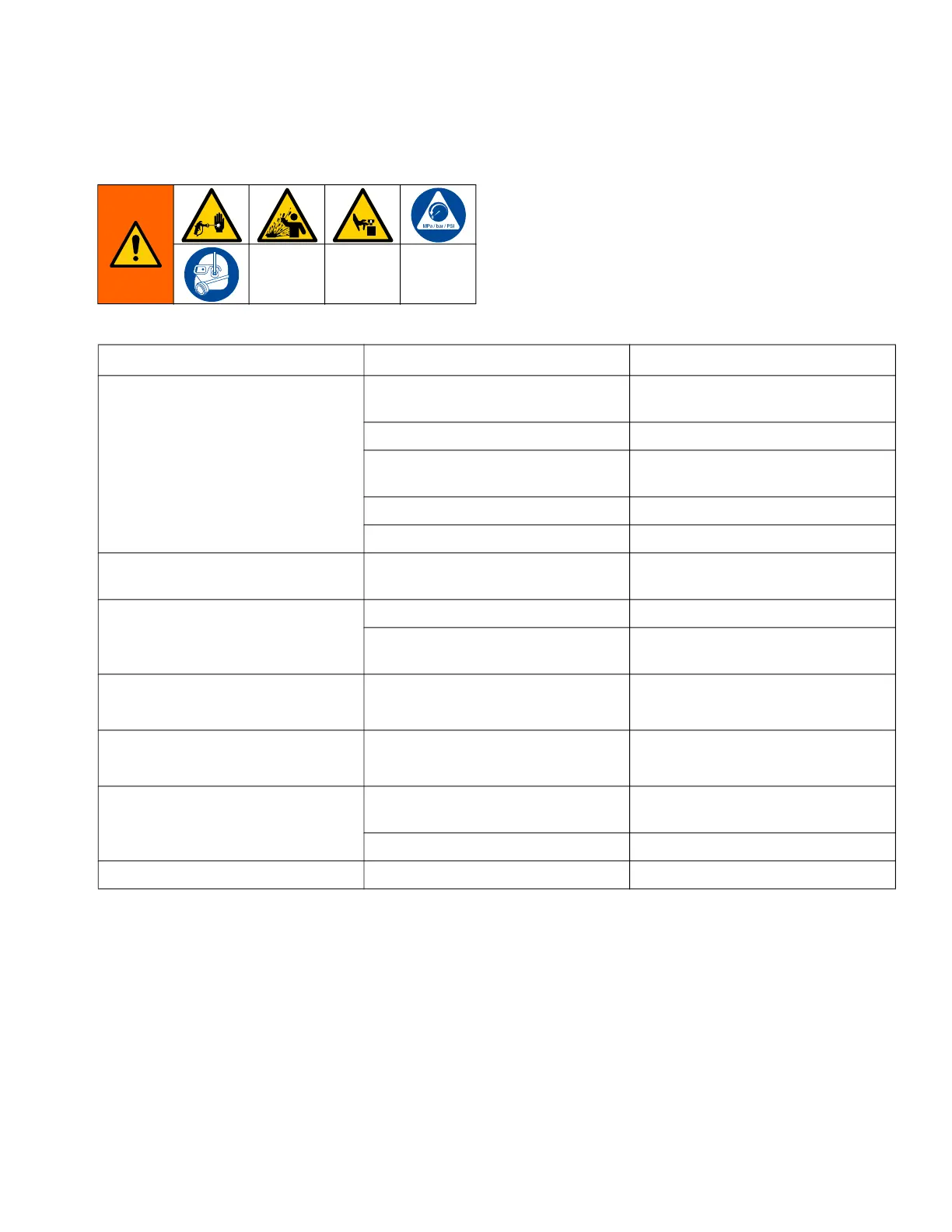

Problem Cause Solution

Pump fails to operate. Inadequate air supply pressure or

restricted air lines

Increase air supply; clear

Closed or clogged dispensing valve Open; clear

Clogged fluid lines, hoses, valves,

etc.

Clear*

Damaged air motor Service air motor

Exhausted fluid supply Refill and re-prime or flush

Continuous air exhaust Worn or damaged air motor gasket,

packing, seal, etc.

Service air motor

Erratic pump operation Exhausted fluid supply Refill and re-prime or flush

Held open or worn intake valve or

piston packings

Clear; service

Pump operates, but output low on

up stroke

Held open or worn piston packings Clear; service

Pump operates, but output low on

down stroke

Held open or worn intake valve Clear; service

Pump operates, but output low on

both strokes

Inadequate air supply pressure or

restricted air lines

Increase air supply; clear

Closed or clogged valves Open; clear

Fluid is coming out of the muffler Worn or damaged throat seal Repair

Loading...

Loading...