Repair

14 308485R

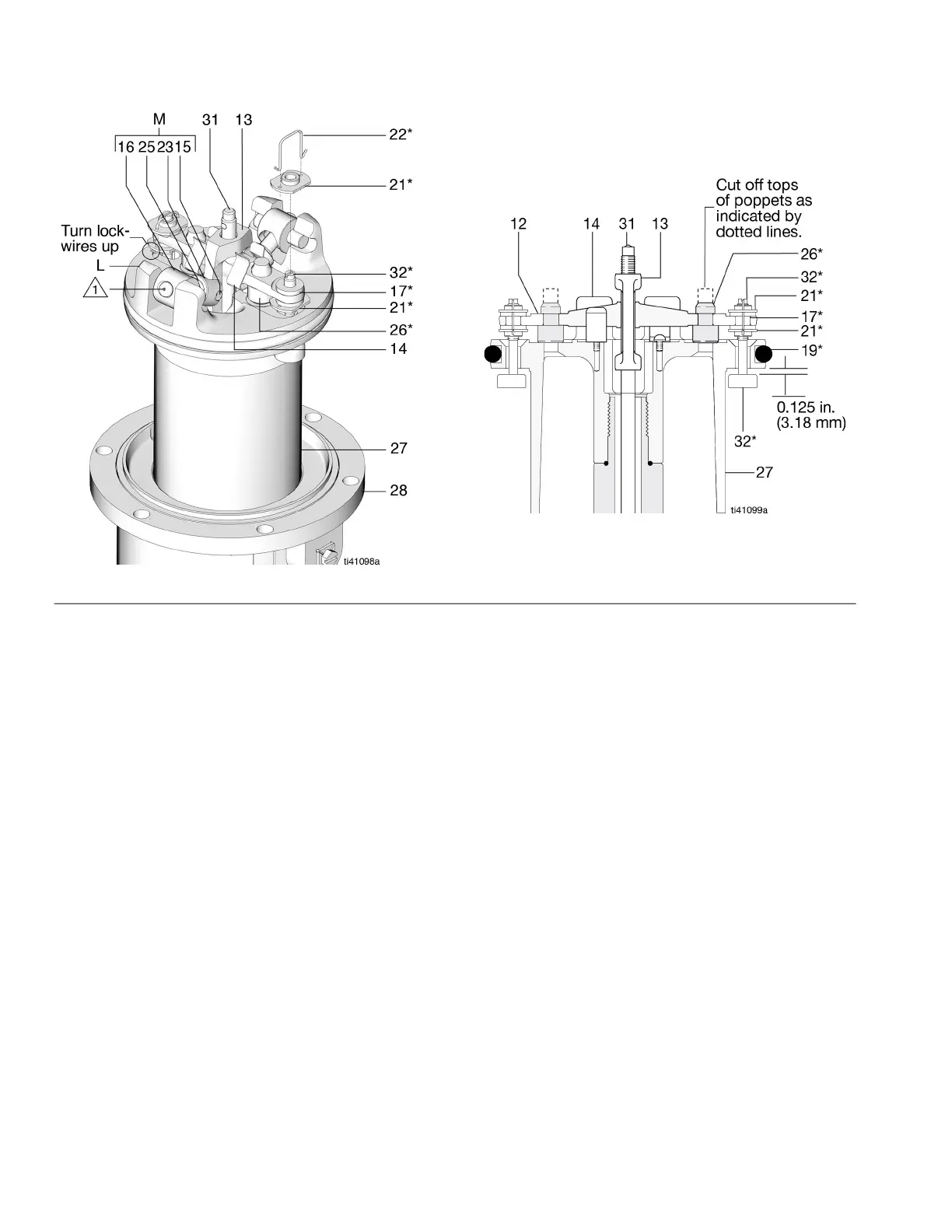

Reassembly

Ensure that all necessary parts are on hand. Air Motor

Repair Kit 207385 includes repair parts for the motor.

For best results, use all of the parts in the kit. Parts

included in the kit are marked with an asterisk in the

text and drawings, for example (19*). See Air Motor

Parts List, page 19.

1. Place the piston rod (29) flats in the vise with the air

motor facing up.

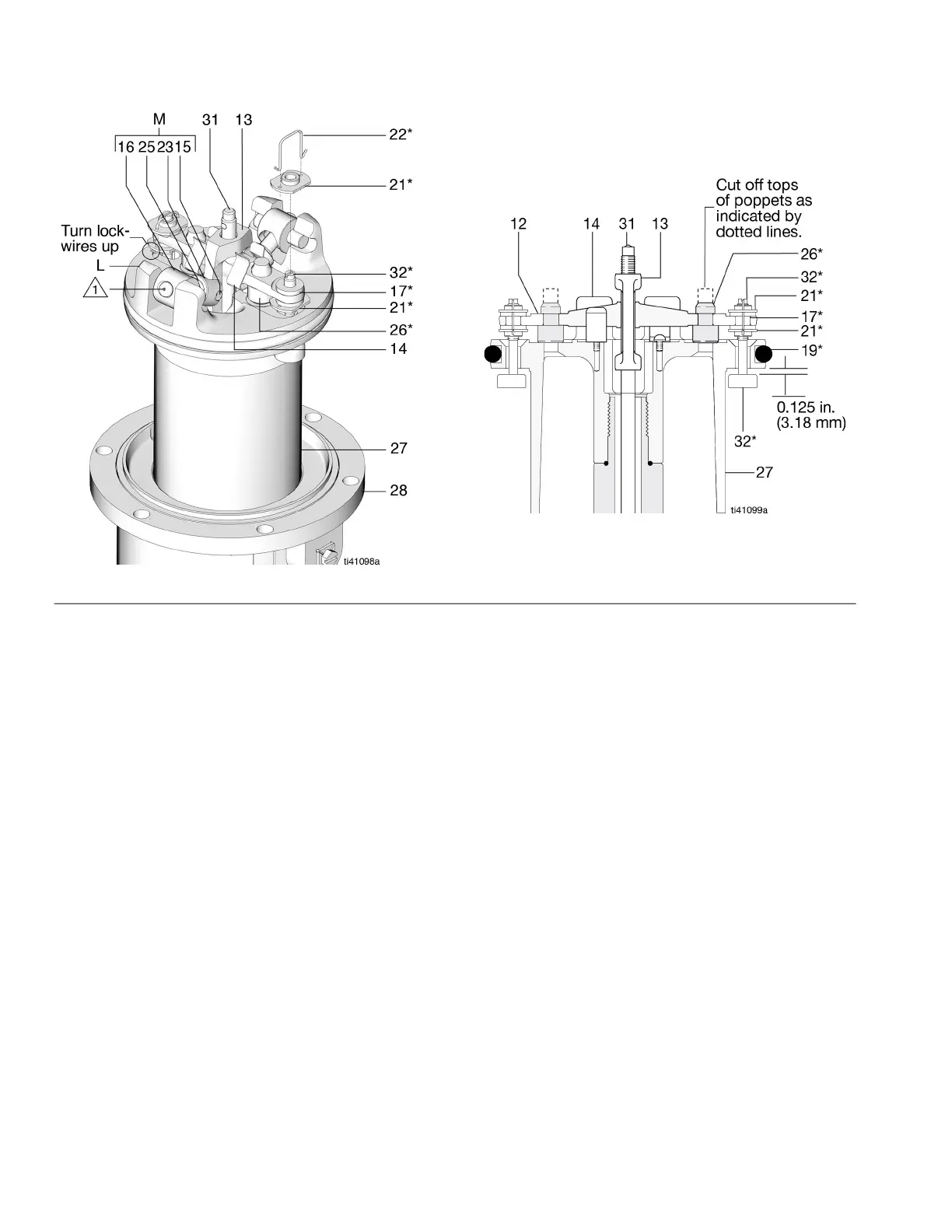

2. Pull the exhaust valve poppets (26*) into the valve

actuator (12), and clip off the top parts of the

poppets (shown with dotted lines in the Cutaway

View in F

IG. 4).

3. Install the grommets (17*) in the actuator (12), place

the inlet valve poppets (32*) in the piston, and

thread the bottom valve nuts (21*) onto the inlet

valve poppets until there are a few threads left

before the threads run out.

NOTE: If the valve nuts are threaded too far down onto

the poppets, they will run off of the threaded part of the

poppets.

4. Grease heavily and place the trip rod (31) in the

piston, place the actuator (12) in the yoke (13), and

place the well-greased actuator/yoke assembly in

the piston, with the trip rod going through the

center holes of the actuator and yoke and the inlet

valve poppets (32*) going through the grommets

(17*).

5. Thread the top valve nuts (21*) onto the inlet valve

poppets (32*) until one thread of the inlet valve

poppets is exposed above the valve nuts.

6. Install the toggle pins (15) in the yoke (13), place the

toggle arm (23) ends of the toggle assembly (M)

onto the toggle pins, and snap the pivot pin (16)

ends of the toggle assembly into the lugs (L).

7. Measuring with the gauge (Part No. 171818), create

0.125 in. (3.18 mm) of clearance between the inlet

valve poppets (32*) and the piston seat when the

inlet valve is open. See the Cutaway View in F

IG. 4.

NOTE: Adjust the distance between the inlet valve

poppets and the piston seat by turning the top valve

nuts (21*).

8. Hand-tighten the bottom valve nuts (21*) securely.

FIG. 4 Air Motor and Throat

Cutaway View

Loading...

Loading...