Repair

10 306982ZAE

Reassembly

1. Clean all the parts carefully in a compatible solvent

and inspect for wear or damage. Use all the repair

kit parts during reassembly and replace other parts

as necessary.

2. Check the polished surfaces of the piston, piston

rod and cylinder wall for scratches or wear. A

scored rod will cause premature packing wear and

leaking.

3. Lubricate all parts with a light, waterproof grease.

4. Be sure the o-rings are in place. Slide the piston

rod down through the throat bearing and lower the

piston (Y) into the air motor base (J).

5. Pull the exhaust valve poppets (X**) into the valve

actuator (V) and clip off the top part shown with

dotted lines. See F

IG. 4.

6. Install the transfer valve poppets (R**) onto the

valve stems (O**), then reassemble the valve stems

(O**), bottom adjusting nuts (Q**), grommets (P**),

and top adjusting nuts (M**) on the piston (Y).

Assemble the trip rod (H), valve actuator (V), trip rod

yoke (K) and toggle assemblies (E) on the piston.

See F

IG. 4.

7. Set gap on inlet valve (N) using the 125 in. (3.18

mm) side of gauge 171818. Rotate valve stem (O**)

until snug against gauge, then back off until valve

stem slot is lined up with wire holes in valve nut

(M**) (do not back off more than 1/2 turn). See F

IG.

4 on page 9. Install lockwires (L**) in the adjusting

nuts M** and Q**).

8. Snap the toggle assemblies (E) to the up position.

Reinstall the cylinder (G) and hold the trip rod (H) in

place with tool 207579. Apply a medium strength

thread locking compound to the threads of the trip

rod (H) and assemble the cap nut (F) to the trip rod

(H). Torque the cap nut (F) to 60 lb-in (6.8) N-m).

Install cap nut (F) into cylinder (G).

9. Before remounting the pump, connect an air hose

and run the pump slowly, at about 40 psi (0.28

MPa, 2.8 bar) to ensure that it operates smoothly.

10. Reconnect the ground wire before regular

operation of the pump.

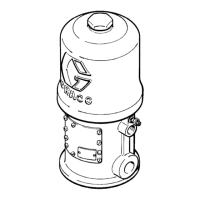

Throat Packing Service for In-Line Pump

Model 205647

NOTE: See FIG. 5 on page 11 and Parts on page 13.

1. Clamp the pump in a vise and unscrew the

displacement cylinder (CC) from the air motor base

(J). Pull the displacement cylinder away from the air

motor until the cotter pin (DD) which secures the

displacement pump connecting rod to the air motor

piston rod (FF) is visible.

2. Remove the cotter pin (DD) and unscrew the pump

connecting rod (EE) from the air motor piston rod

(FF). Remove the cylinder (G) from the air motor

base (J) as described under Disassembly on page

8.

3. Remove one louvered air exhaust plate (BB) and

unscrew the throat packing nut (HH), using a

spanner wrench or a 0.22 in. (5.6 mm) diameter rod.

Remove the spacer and packing from the base and

packing nut. Clean the throat packing area in the

base and the packing nut. Clean and inspect all

parts and replace as necessary.

4. Lubricate the packings, piston rod and piston

flange with a light waterproof grease. Reinstall the

spacer and packing in the base and packing nut.

Be sure the lips of the v-packings face down. See

Detail B. Screw the packing nut loosely into the

base. Carefully slide the piston rod down through

the throat packing and lower the piston into the

base. Tighten the packing nut securely. Reinstall

the plate (BB) and cylinder (G). Reassemble the air

motor to the displacement pump.

To avoid fire and explosion, always ground

equipment and waste container. To avoid static

sparking and injury from splashing, always flush at

the lowest possible pressure.

The piston in the air motor, located behind the air

motor plates, moves when air is supplied to the

motor. Moving parts can pinch or amputate your

fingers or other body parts. Therefore, never operate

the pump with the air motor plates removed.

Loading...

Loading...