31

9.4 MINIMUM RECOMMENDED TEST9.4 MINIMUM RECOMMENDED TEST

9.4 MINIMUM RECOMMENDED TEST9.4 MINIMUM RECOMMENDED TEST

9.4 MINIMUM RECOMMENDED TEST

EQUIPMENTEQUIPMENT

EQUIPMENTEQUIPMENT

EQUIPMENT

VOLTOHM METER — Simpson #260, Fluke

73 or equal

AMMETER — Simpson #150 or equal

OSCILLOSCOPE — Tektronix #323 or

equal

SCOPE PROBE — Tektronix #P600T or

equal; set on X10 scale for use on circuit

boards, X100 scale for power components.

TORQUE WRENCH — For power components,

with hex key sockets

HAND TACHOMETER — For measuring motor

speed

9.59.5

9.59.5

9.5

DIODE, TRANSISTOR AND SCRDIODE, TRANSISTOR AND SCR

DIODE, TRANSISTOR AND SCRDIODE, TRANSISTOR AND SCR

DIODE, TRANSISTOR AND SCR

TEST PROCEDURETEST PROCEDURE

TEST PROCEDURETEST PROCEDURE

TEST PROCEDURE

Remove the input power and wait for the BUS PWR

LED to extinguish. After checking to confirm that no

voltage is present from J2-9 to J5-20 on the Control

Board, visually inspect the drive for any physical evi-

dence of a failure such as:

1. Leaking or distorted capacitors

2. Discolored component

3. Loose connections

4. Cracked or broken semiconductors

Check all power semiconductors and large capacitors

for shorts. All fuses should be checked. For proper

testing methods of diodes, transistors and SCRs see

Section

9.5.1. These steps will generally locate most of

the problems that may occur under normal operating

conditions and should be performed first.

9.5.19.5.1

9.5.19.5.1

9.5.1

DIODE, TRANSISTOR AND SCRDIODE, TRANSISTOR AND SCR

DIODE, TRANSISTOR AND SCRDIODE, TRANSISTOR AND SCR

DIODE, TRANSISTOR AND SCR

TESTINGTESTING

TESTINGTESTING

TESTING

All leads, including the bus bars, must be disconnected

from the device being tested. The resistance values

shown are for good components. If a reading is in doubt,

compare it to a known good component. Exact values

cannot be given, as readings will vary with meter and

scale used.

Diodes, transistors, and SCRs may be tested by using

the procedure outlined in this section to check for short

or open circuits. When readings fall into questionable

or faulty areas, do not replace the device until a

comparison test is made with a known good device.

Recheck the components out of the circuit. Always use

the same ohmmeter when performing comparison tests.

Failure of a power transistor or SCR indicates the need

to completely check out the control board. This should

be performed by a factory trained technician, or the

control board should be replaced. Failure to check out

or replace the board could cause repeated failure.

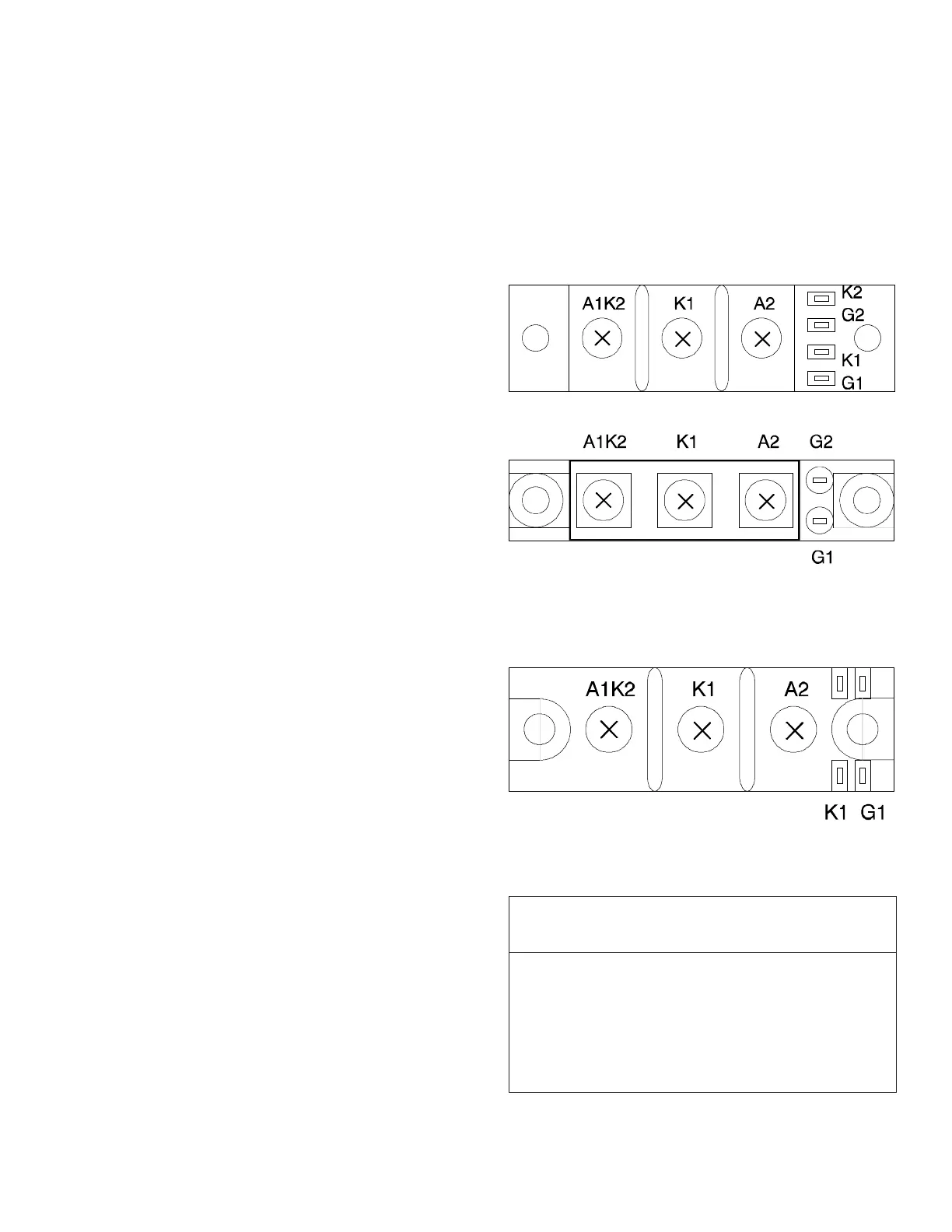

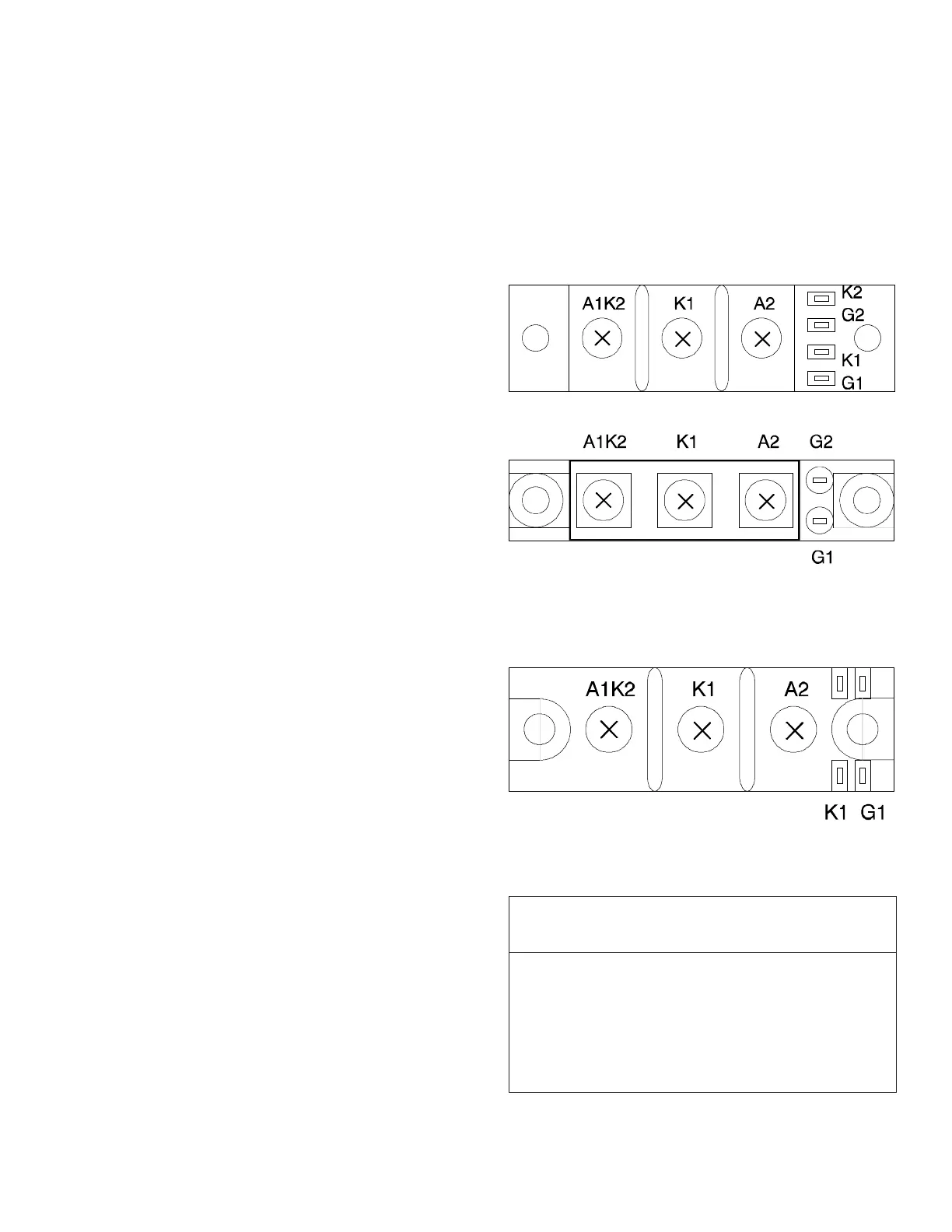

INPUT/OUTPUT SCR MODULESINPUT/OUTPUT SCR MODULES

INPUT/OUTPUT SCR MODULESINPUT/OUTPUT SCR MODULES

INPUT/OUTPUT SCR MODULES

Input SCR, all models, and

Output SCR 7.5 through 53 amp

1

Either style may be used

Output SCR, 65 through 100 amp

1

1

Refer to the “Output Drive Current” rating on the

plastic cover over control board for this value.

Meter Lead Resistance Reading

Positive Negative (ohms)

A1K2 K1,A2 >10,000

K1, A2 A1K2 >10,000

A1K2 G2 <1,000

G2 A1K2 <1,000

K1 G1 <1,000

G1 K1 <1,000

K2 G2

Loading...

Loading...