13

furnished by resistor R34 and capacitor C23.

4.23 ANALOG-TO-DIGITAL (A/D)

CONVERSION

Integrated circuit U6 is the analog-to-digital converter.

Included on this integrated circuit are auto-zero

functions, auto-polarity, and the digital and analog

functions necessary to perform dual slope integration

conversion to 20,000 counts (4-1/2 digits). The

weight signal voltage is applied to the analog input

(pin 10) of U6.

A reference voltage for the conversion is applied to

pin 2 of U6. The reference voltage, nominally 1 Volt,

is derived from the load cell transducer excitation

voltage, by the divider network consisting of resistors

R29, R30, and potentiometer P1. Adjusting P1 sets

the “span” or weight calibration of the scale.

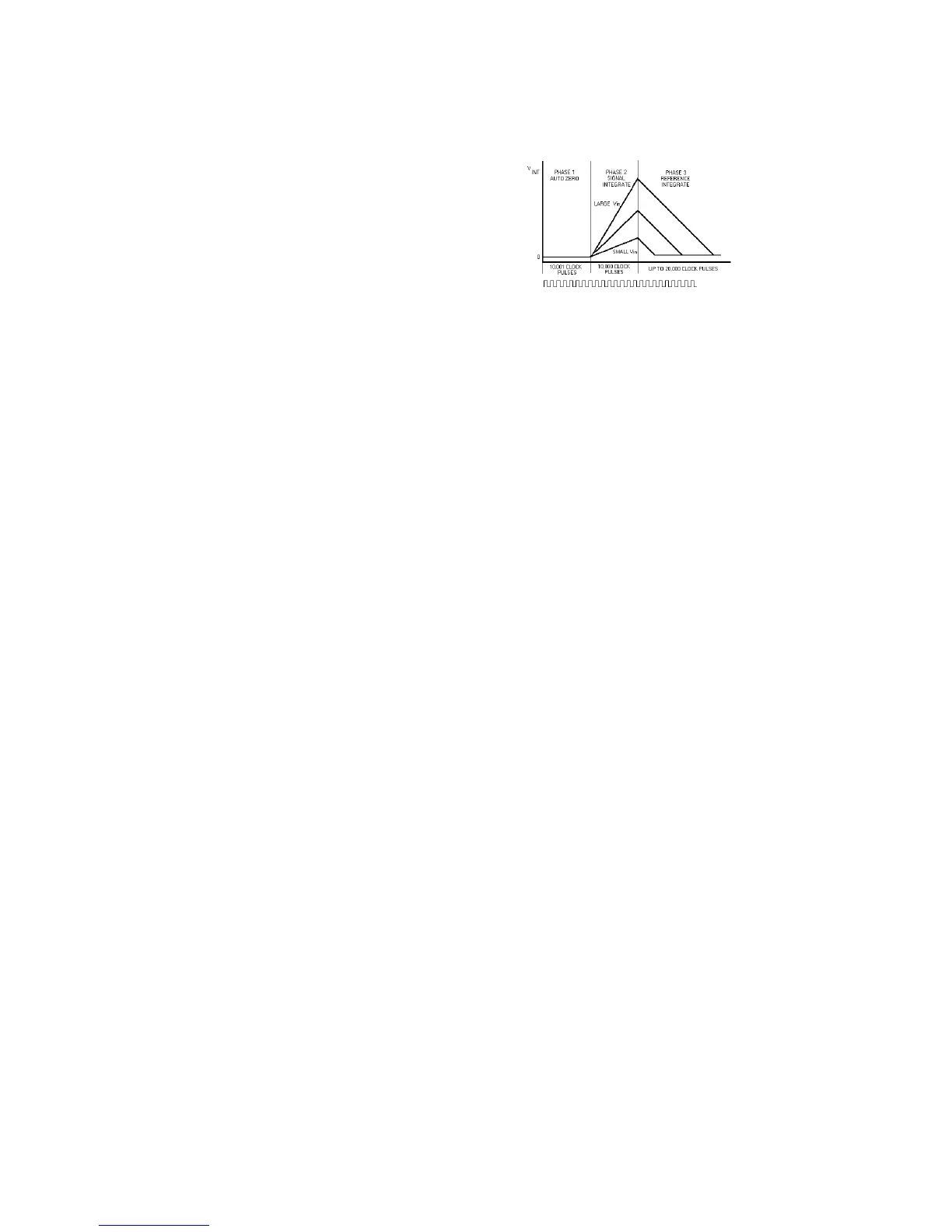

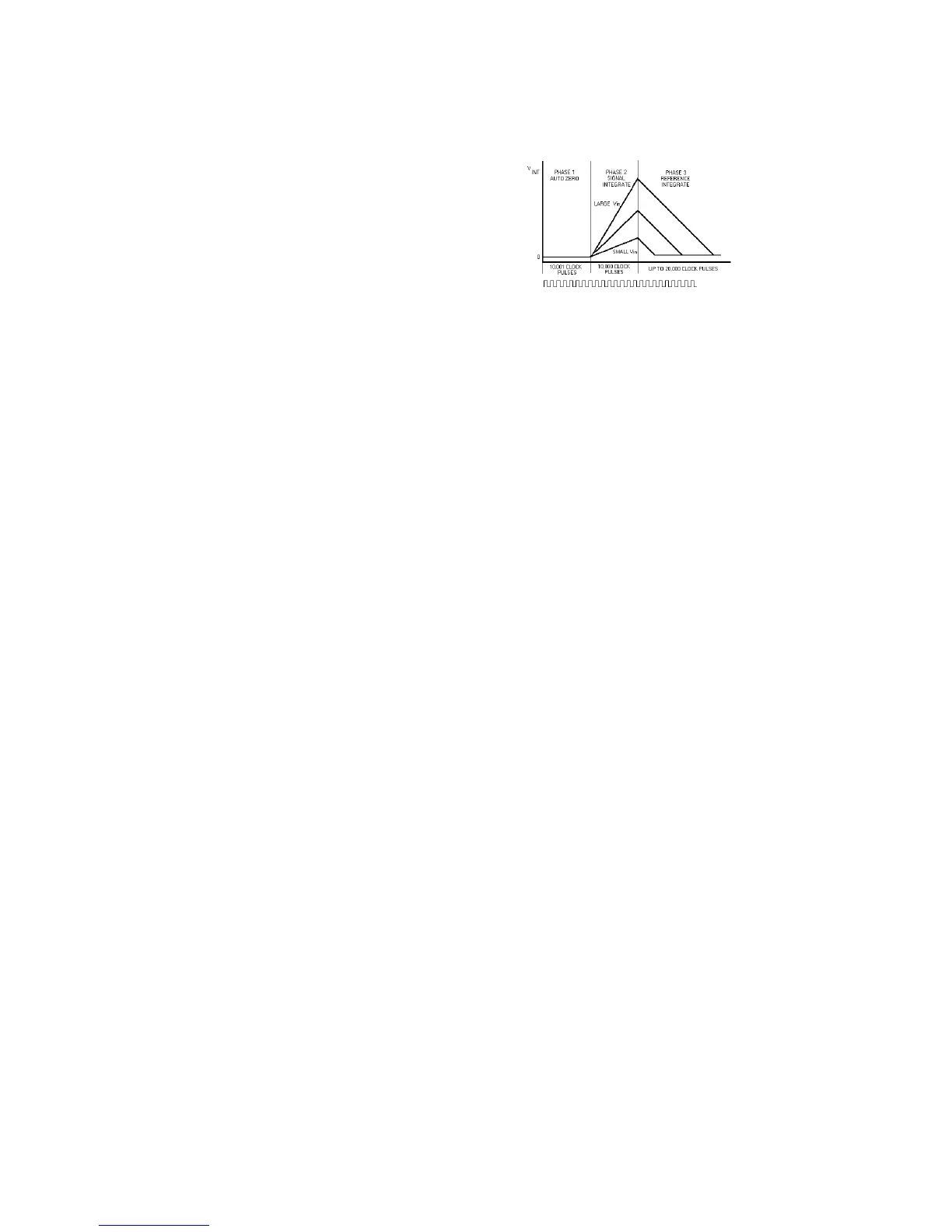

The system clock, applied at pin 22 of U6, is used to

precisely time and control the phases of the dual

slope conversion process. Refer to the converter

timing diagram when reading the following

description.

4.23.1 PHASE 1, AUTO ZERO

During auto zero, the errors in the analog

components (offset voltages of buffers, comparators,

etc.) will be automatically nulled out. This is

performed by internal logic that disconnects the input

pins (9 & 10) from the applied analog signal, connects

them to ground, then closes an internal feedback loop

such that offset error information is stored in the “auto

zero” capacitor, C21. Also during this phase,

“reference capacitor” C22 is charged to the voltage

present on “Vref” (pin 2 of U6).

4.23.2 PHASE 2, SIGNAL INTEGRATE

The input signal is reconnected and then integrated

for exactly 10,000 clock pulses. On completion of the

integration period, the voltage V is directly

proportional to the input voltage, corresponding to the

weight applied to the scale. Capacitor C20 is the

integration capacitor, with resistor R32 setting the

integration current. At the end of this phase the input

signal polarity is determined.

A/D CONVERTER TIMING DIAGRAM

4.23.3 PHASE 3. REF. INTEGRATE, SIGNAL

DEINTEGRATE

The input to the integrator is switched from the input

signal to reference capacitor C22. Internal switches

connect capacitor C22 to the integrator input so that

its polarity is opposite that of the previously applied

input signal. This causes the integrator to discharge

back towards zero. The number of clock pulses

counted between the beginning of this cycle and the

time when the integrator output passes through zero

is a digital measure of the magnitude of the input

signal. This count is stored in an internal latch on U6

for output to the microcomputer.

4.23.4 ZERO INTEGRATOR PHASE

One minor additional phase is included to insure that

the integration capacitor C20 is fully discharged to

zero volts. This typically lasts 100-200 counts.

4.24 CLOCK CIRCUIT

A clock is required for the A/D converter, integrated

circuit U6. The clock signal is generated internally in

microcomputer U7 and appears on port pin “P1.0”.

The frequency is internally set by the

microcomputer’s software and is nominally 120 KHZ.

4.25 POWER SWITCHING, VOLTAGE

REGULATION AND SUPPORT CIRCUITRY

Additional circuitry is included to switch the battery

supply, provide voltage regulation and detect low

battery voltage conditions.

4.25.1 BATTERY SWITCHING

In order to conserve battery life, the battery supply is

switched on and off as needed by the scale.

Loading...

Loading...