6

Grant Vortex External Module

6 Frost protection - Your Installer may have fitted a

frost thermostat. If not, and you are likely to be

away for a short time, leave the boiler on with the

boiler thermostat set at a low setting. For longer

periods the boiler and system should be drained.

Contact your Service engineer for draining and

filling the system.

The control panel of the External modules includes

a built-in frost thermostat factory set to 5°C.

Note: For Vortex External modules we recommend

that a combined antifreeze and corrosion inhibitor

be used in the primary water system.

7 Cleaning and servicing - Lightly wipe over the

case with a damp cloth and a little detergent. Do

not use abrasive pads or cleaners.

You must have your boiler serviced at least once a

year to ensure safe and efficient operation. Contact

your Service engineer for further details.

Warning note - External equipment operated at

230 volts should not be serviced or repaired

under adverse weather conditions.

8 Failure of electricity supply - If the electricity

supply fails, the boiler will not operate. It should

relight automatically when the supply is restored.

The boiler requires a 230/240 V ~ 50 Hz supply. It

must be protected by a 5 Amp fuse.

Warning: This appliance must be earthed.

If your boiler is operating on a sealed heating system,

the installer will have pressurised the system and

should have told you (or set it on the pressure gauge)

the system pressure when cold (this is normally

between 0.5 and 1.0 bar, which will increase slightly

when hot). If the pressure (when cold) is below the set

pressure mentioned above, you can re-pressurise the

system. If the system requires frequent re-pressurising,

ask your Installer or Service engineer to check the

heating system for leaks and to check the expansion

vessel air charge.

An automatic filling system should not be used on a

sealed central heating system.

The boiler or system will be fitted with an automatic

air vent to remove air from the system. Any air trapped

in the radiators should be removed by venting the

radiators using the vent screw at the top of each

radiator. Only vent a radiator if the top is cool and the

bottom is hot. Excessive venting will reduce the

system pressure, so only vent when necessary and

check the system pressure as mentioned above. Re-

pressurise the system if necessary.

The boiler or system may be fitted with a safety valve

to release excess pressure from the system. If water or

steam is emitted from the end of the safety valve

discharge pipe, switch off the boiler and contact your

Installer or Service engineer.

The expansion vessel air charge must be checked

annually. Failure to maintain an adequate air

charge in the vessel may invalidate the warranty.

To re-pressurise the system by adding water:

1 Only add water to the system when it is cold and

the boiler is off. Do not overfill.

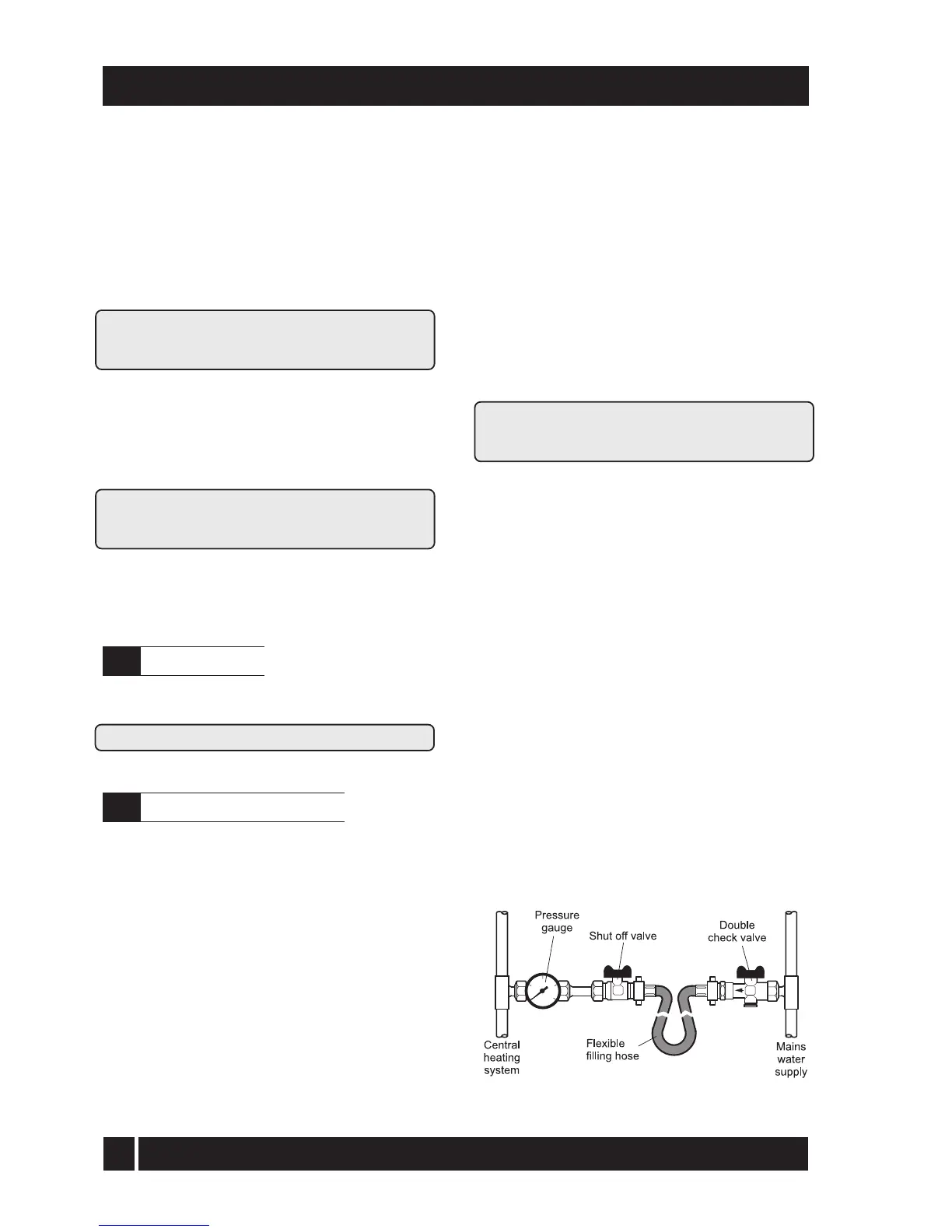

2 Ensure the flexible filling loop (see Fig. B) is

connected and that the shut off valve connecting it

to the boiler is open and the double check valve at

the front is closed.

A valve is open when the operating lever is in line with

the valve, and closed when it is at right angles to it.

3 Gradually open the double check valve on the front

of the filling loop until water is heard to flow.

4 Vent each radiator in turn, starting with the lowest

one in the system, to remove air.

5 Continue to fill the system until the pressure gauge

indicates between 0.5 and 1.0 bar. Close the fill

point valve.

6 Repeat steps 4 and 5 as required.

7 Close the valves either side of the filling loop and

disconnect the loop.

2 - USER INSTRUCTIONS

Electricity supply

2.8

Sealed central heating system

2.9

Sealed system filling loop arrangement - Fig. B

Loading...

Loading...