SOLDERING EXPERIENCE

For

this

project

to w,ork

properlv, you

rnust have

good

solder

connections.

lf

you

have not had

experience

in

soldering,

it is

suggested that beiore

you

start assembl-

ing this

project, you practice

nraking

solder connections

with

odd

lengths

of

rvire

and used components. Observe

the following rules for

proper

soldering techniques.

l.

Use

a 30-to-5O-watt

pencil

type

soldering

iron. Do

not

use a soldering

gun.

2.

Use

only rosin

core solder as supplied

with

your

project.

The

use of any other types of solder

will

void

your

warranty. lf

additional solder

is requir"ed,

use only 60-.10

rosin

core, such as

Kester

,1.1.

Dt)

NOT

USE

ACID

CORE SOLDER or

paste

f luxes.

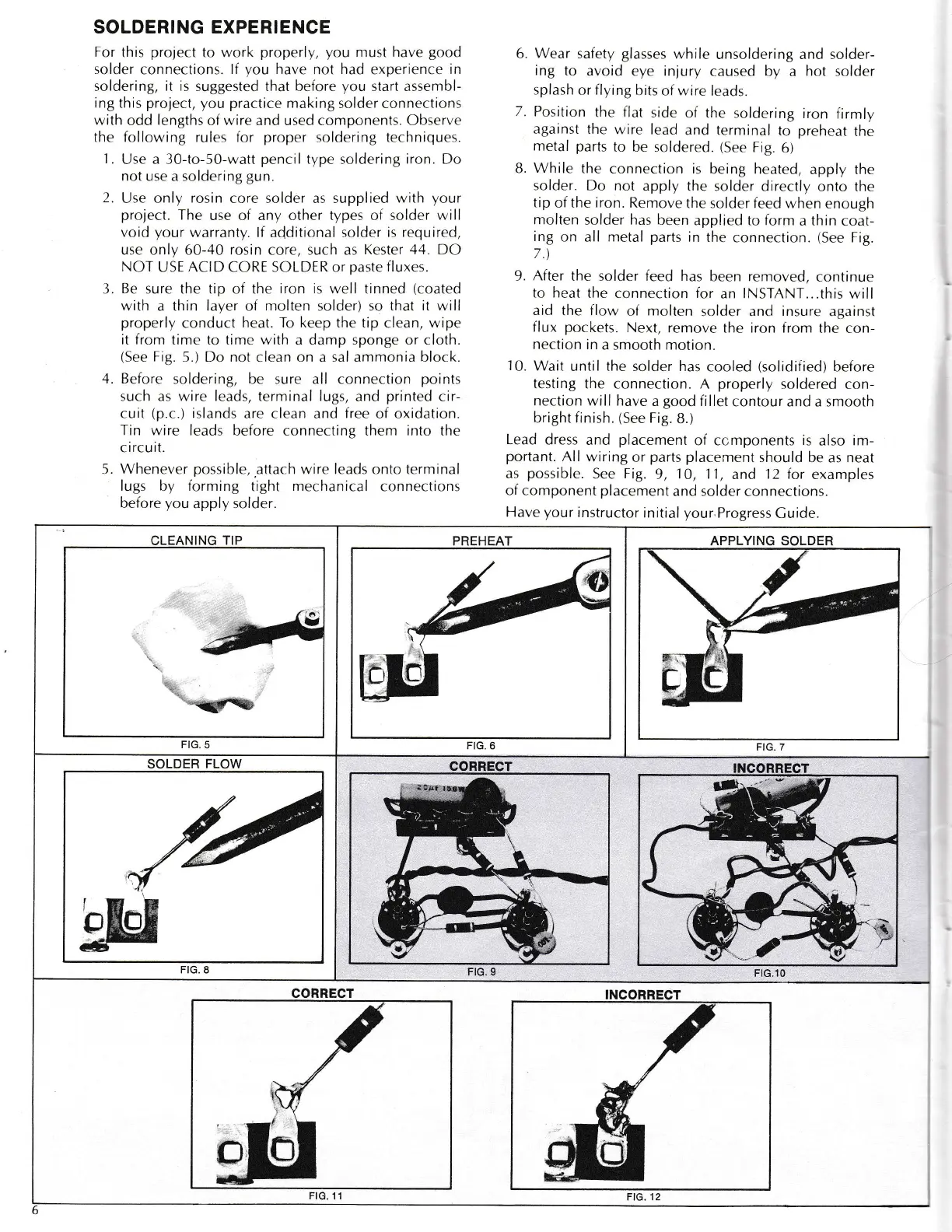

3.

Be

sure the tip of the

iron is

well tinned

(coated

with

a thin layer of

molten

solder) so

that it will

properly

conduct

heat. To keep the tip

clean,

wipe

it from

trme to time with a damp sponge or cloth.

(See

Fig.

5.) Do not clean on a sal ammonia block.

,1.

Before

soldering, be sure all connection

points

such as wire leads, terminal lugs,

and

printed

cir-

cuit

(p.c.)

islands

are clean

and

free

of oxidation.

Trn wire leads

before connecting them

into

the

c

ircu it.

5. Whenever

possible,.attach

wire leads onto terminal

lugs by forming

tight

mechanical

connections

before

you

apply

solder.

6. Wear

safety

glasses

while

unsoldering and solder-

ing

to

avoid eye injury

caused by a

hot

solder

splash

or

flying

bits

of wrre

leads.

7.

Position

the flat

side of the

soldering

iron

firmly

against

thc

wjre lead

and terminal

to

preheat

the

metal parts

to be soldered.

(See

Fig.

6)

B.

While

the

connection is

being heated,

apply the

solder. Do not

apply the

solder directly

onto the

tip

of

the iron.

Remove

the solder

feed

w,hen

enough

molten

solder

has

been

applied to form

a

thrn

coat-

ing

on all nretal

parts

in

the

connection.

(See

Fig.

7.\

9. After

the solder feed has

been removed,

continue

to heat

ihe connection for

an

lNSTANT...this

will

aid the flow

of

molten

solder .tnd insure ag.rinst

flux

pockets.

Next,

remove the iron from

the c-on-

nection

in

a smooth motion.

10.

Wait

until the solder has

cooled

(solidified)

before

testing

the

connection. A

properly

soldered

con-

nection

will have

a

good

fi llet

contour and a smooth

bright

finish.

(See

Fig.

8.)

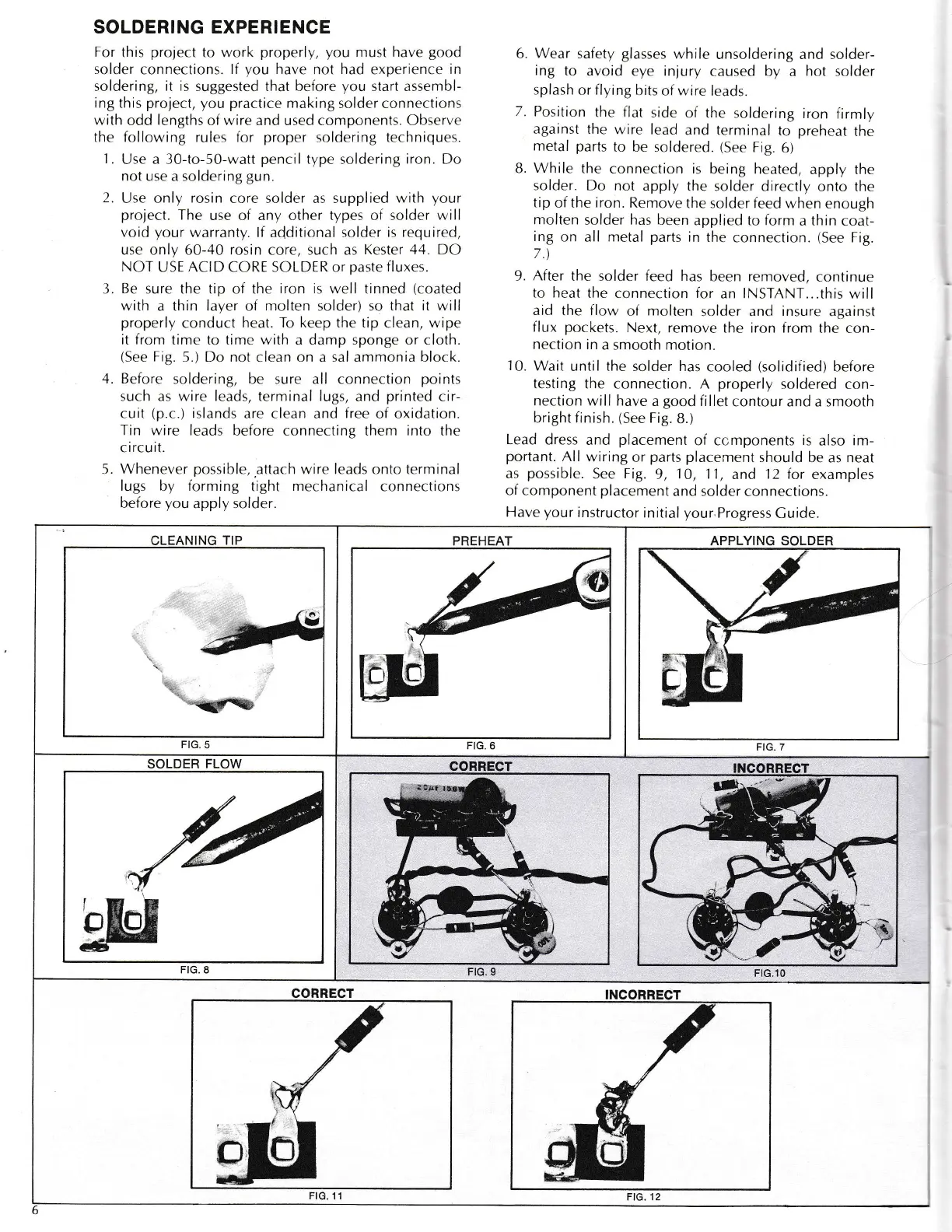

Lead

dress

and

placement

of ccmponents

is

also im-

portant.

All wiring

or

parts

placement

should be

as

neat

as

possible.

See

Fig.

9,

10,

1-l,

and

12 for

examples

of component

placement

and solder

connections.

Have

your

instructor

initial

your

Progress

Cuide.

APPLYING SOLDER

'i,j.

FIG.7

CLEANING

TIP

I

.l:r

''t.

..;yffi

FIG.

5

PREHEAT

FIG.6

SOLDER

FLOW

FIG. 8

CORRECT

FtG.10

CORRECT

FtG.

11

m

_

i/_.-_.-

-t

Loading...

Loading...