ENGLISH

Instruction manual - VARIABLE SPEEDSWIMMING POOL PUMP16

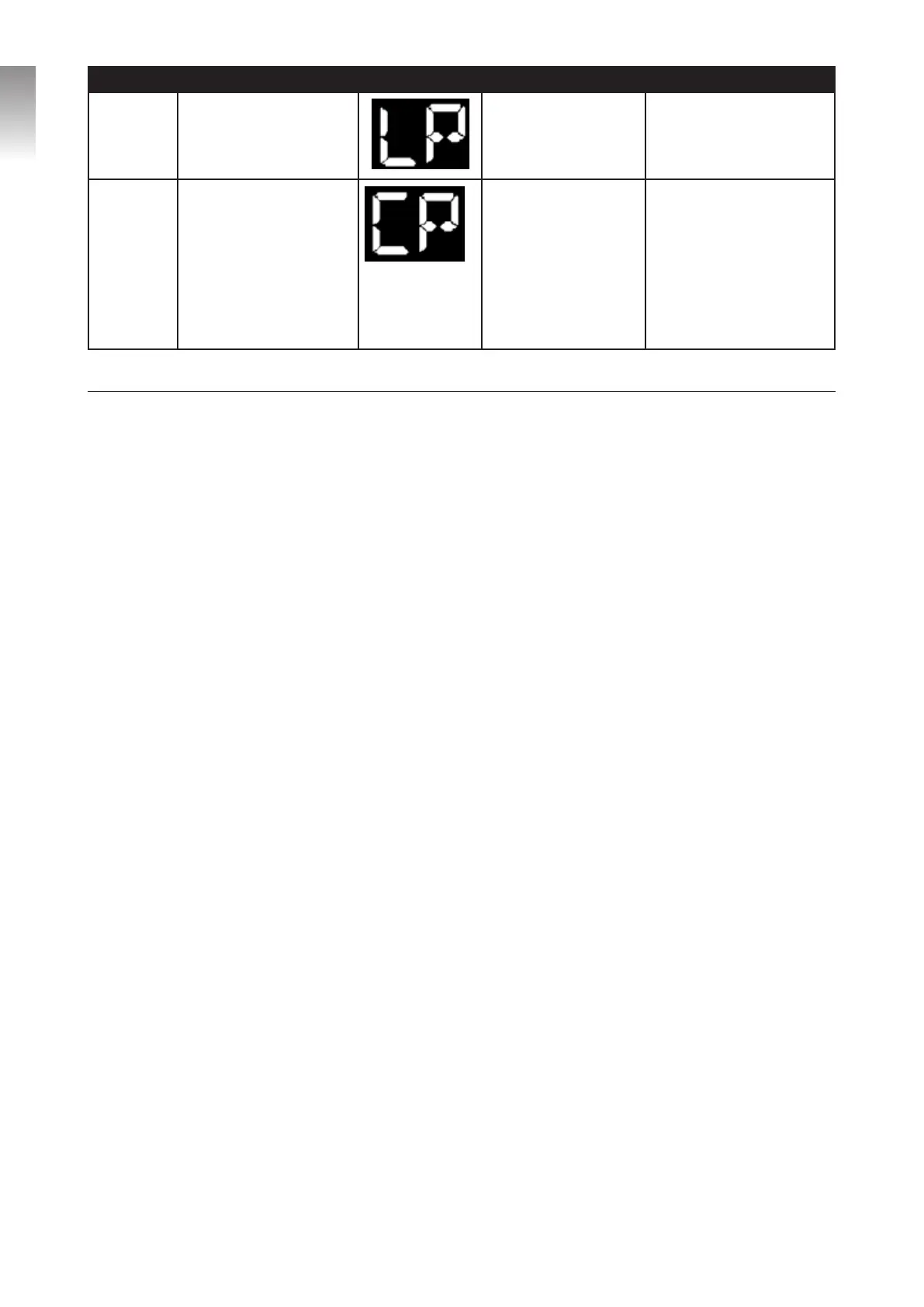

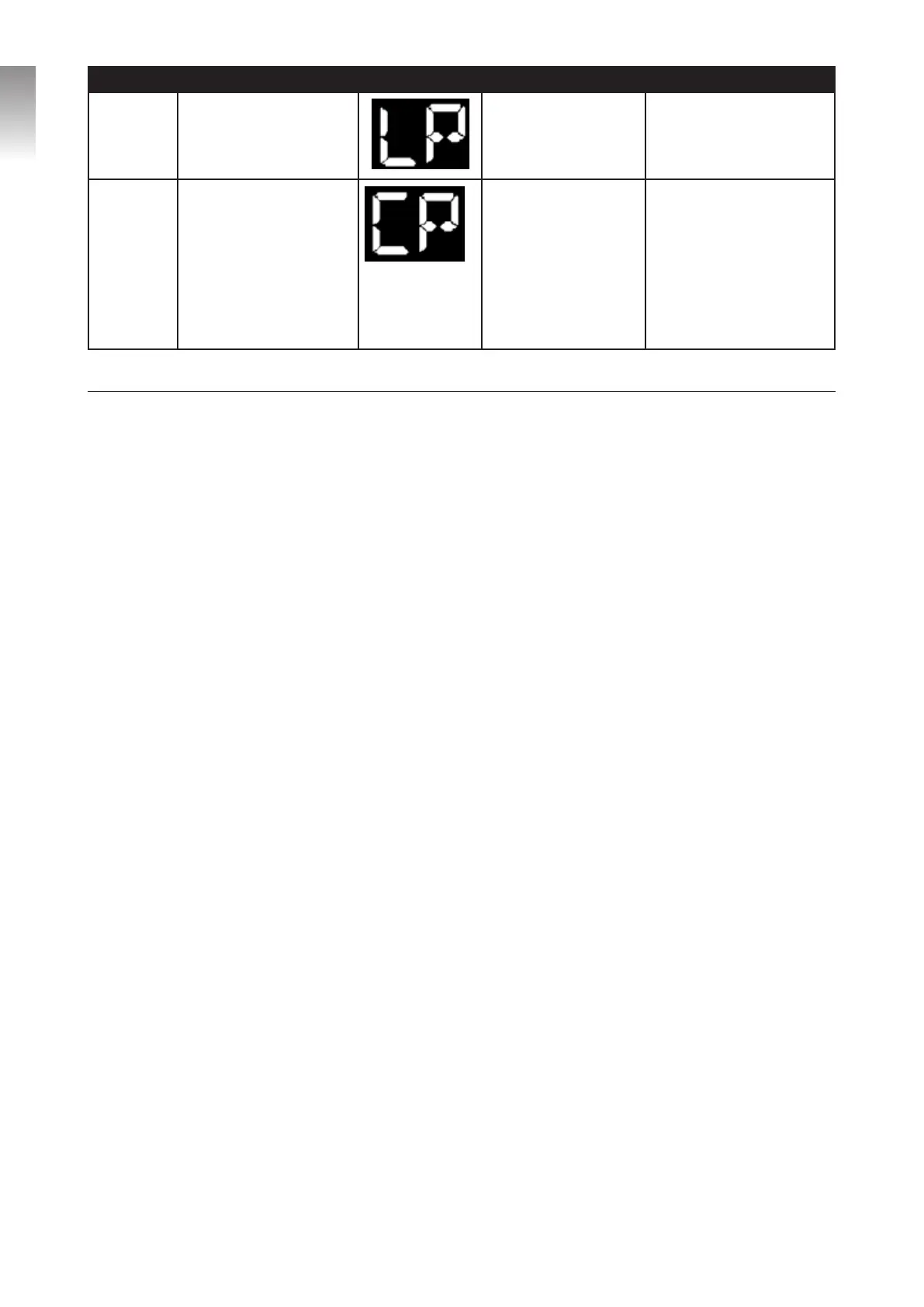

Code Fault Display Possible causes Solution

LP Phase Loss There is a phase wire

missing connecon at

the input.

1. The pump will try to

restart automacally in 6

seconds aer the phase

wire is well connected.

CP Communicaon Failure

1. Loose connec-

on cable between

display PCB and main

PCB;

2. Connecon cable

damaged.

1. Aer communicaon

is restored, the pump will

restart automacally.

2. Check the connecon

cable.

3. Send it to a profes-

sional repair staon for

repair.

9. GENERAL POOL PUMP TROUBLE SHOOTING GUIDELINES:

Make sure the terminal board connections agree with the wiring diagram on motor data plate label. Be sure

motor is wired for available field supply voltage (see pump operating label).

1. Improper or loose wiring connections; open switches or relays; tripped circuit breakers, GFCI’s, or blown fuses.

Solution: Check all connections, circuit breakers, and fuses. Reset tripped breakers or replace blown fuses.

2. Manually check rotation of motor shaft for free movement and lack of obstruction.

3. If you have a timer, be certain it is working properly. Bypass it if necessary.

1. Low voltage at motor or power drop (frequently caused by undersized wiring or extension cord use).

Solution: Contact qualified professional to check that the wiring gauge is heavy enough.

2. Motor may be overheating due to direct sunlight or low water level in the pump basket.

Solution: Check water flow to insure uniform amount of water coming to the pump.

NOTE - Your pump motor is equipped with an “automatic thermal overload protector.” The motor will automati

-

cally shut off if power supply drops before heat damage can build up causing windings to burn out. The “thermal

overload protector” will allow the motor to automatically restart once the motor has cooled. It will continue to

shut off until the problem is corrected. Be sure to correct cause of overheating.

1. Impeller jammed with debris.

Solution: Have a qualified repair professional open the pump and remove the debris.

2. Motor is frozen either form months in the carton after manufacturing or from over winter storage.

Solution: Insert a flat bladed screw driver into the slot at the back end of the motor shaft and turn motor shaft un

-

til it moves freely. You may have to remove the protective metal cap from some models to access the motor shaft.

NOTE – All pumps are run tested with water before leaving the factory.

1. Empty pump/strainer housing

Solution: Make sure pump/strainer housing is filled with water and cover o-ring is clean. Ensure o-ring is prop

-

Loading...

Loading...