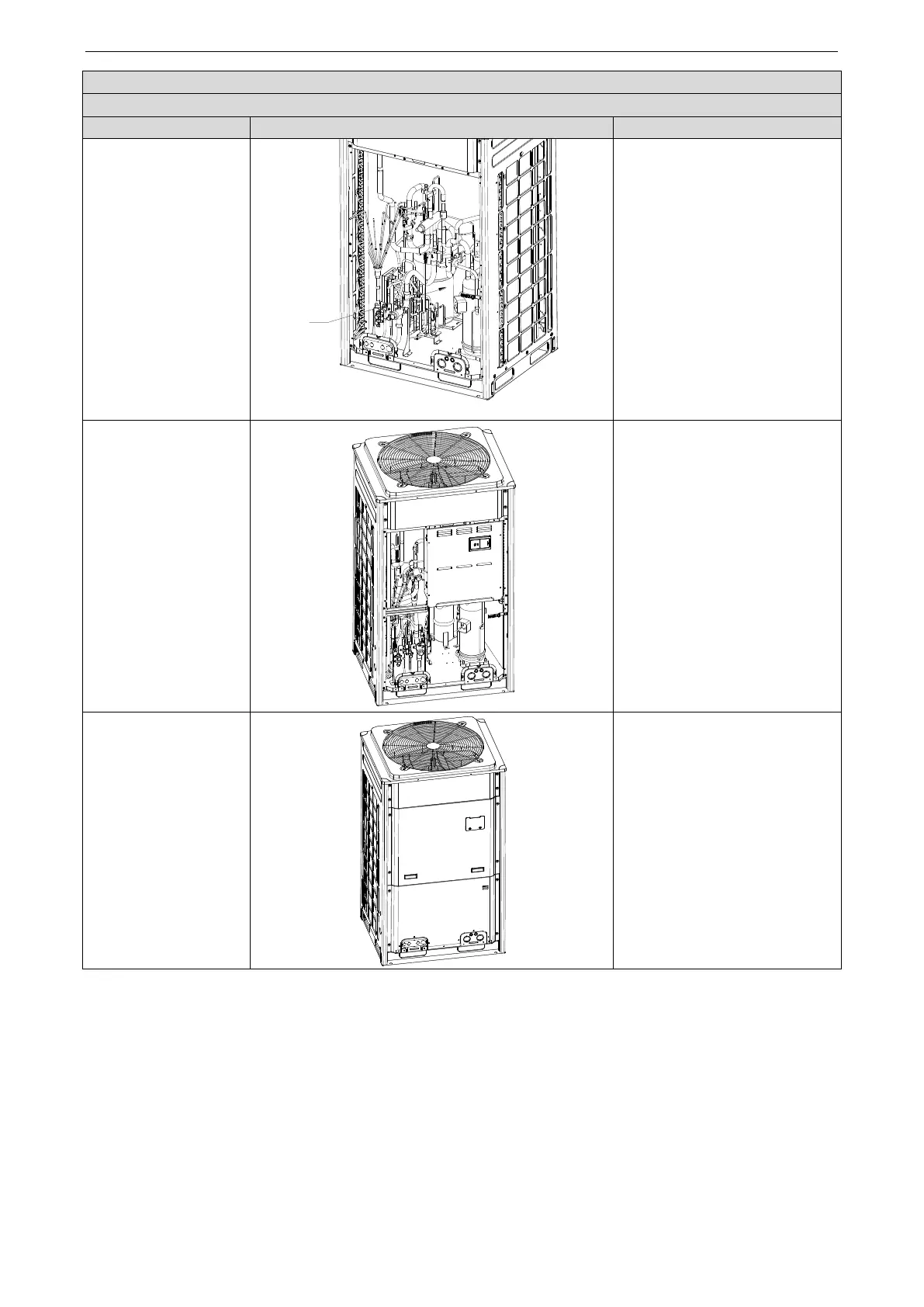

●Put the gas/liquid separator

based on the position of the

suction and discharge pipes and

weld the pipes with the gas/liquid

separator.

●During welding, charge nitrogen

into the pipes. The pressure

should be controlled within

0.5±0.1 kgf/cm2 (relative

pressure).

Note: Avoid nearby parts from

being burnt during welding.

●Screw the gas/liquid separator.

●Check various parts and

connecting lines.

●

If no problem is found, hook the

front panels and tighten the

screws.

Loading...

Loading...