DC Inverter U-match Series Cassette Type Unit

28

(7) Slightly open the liquid valve and let some refrigerant go to the connection pipe

to balance the pressure inside and outside of the connection pipe, so that air will

not come into the connection pipe when removing the hose. Note that the gas

and liquid valve can be opened fully only after the manifold valve assembly is

removed.

(8) Place back the caps of the liquid valve, gas valve and also the service port.

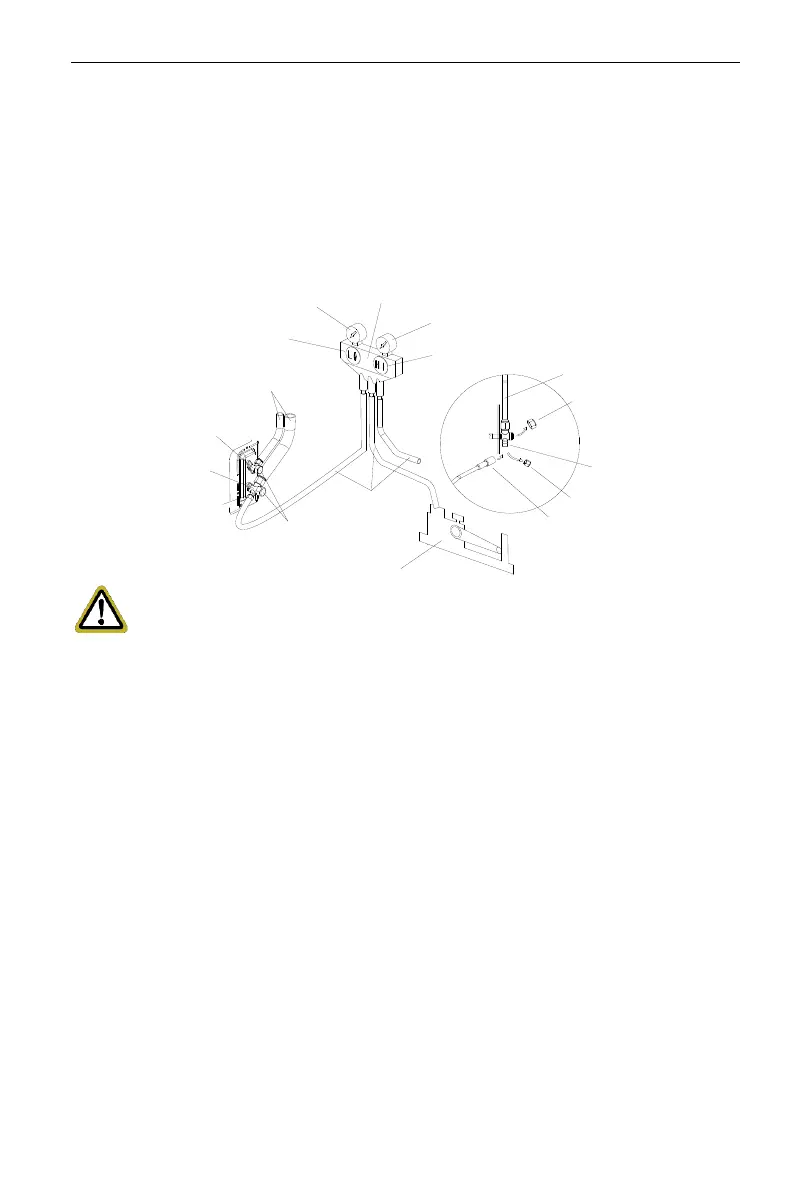

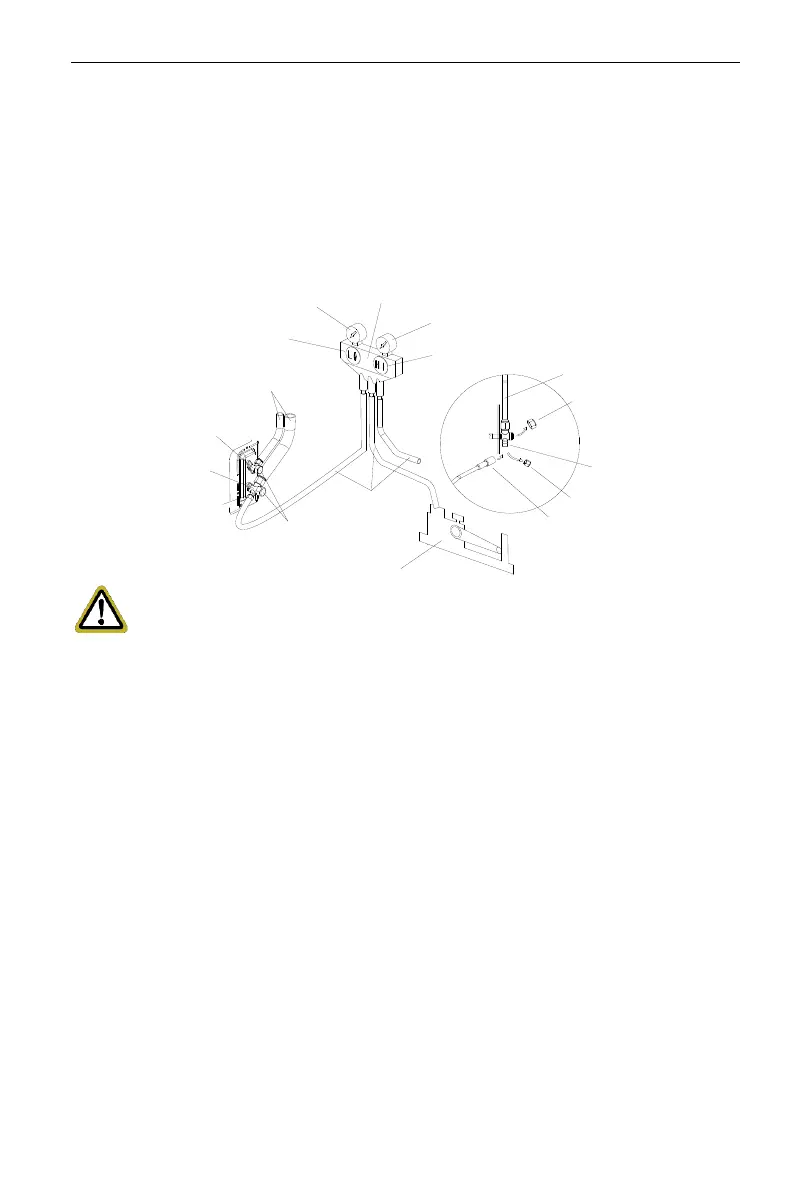

Hose with the valve pin

gauge manifold

Pressure gauge (Low-pressure)

Pressure gauge (Hi-pressure)

Switch (Low-pressure)

Switch (Hi-pressure)

Connection pipe (to indoor unit)

Liquid valve

Gas valve

Service port

Cap

Hose

Vacuum pump

Cap

Service pipe

Cap

Connection pipe

Notice:

For large-size units, there are maintenance ports for liquid valve and gas valve.

During evacuation, you may connect the two hoses of the branch valve assembly to

the maintenance ports to speed up the evacuation.

3.2.4.2 Leak Detection Methods

The following leak detection methods are deemed acceptable for systems

containing flammable refrigerants.

Electronic leak detectors shall be used to detect flammable refrigerants, but the

sensitivity may not be adequate, or may need re-calibration. (Detection equipment

shall be calibrated in a refrigerant-free area).

Ensure that the detector is not a potential source of ignition and is suitable for

the refrigerant used. Leak detection equipment shall be set at a percentage of the

LFL of the refrigerant and shall be calibrated to the refrigerant employed and the

appropriate percentage of gas (25 % maximum) is confirmed.

Leak detection fluids are suitable for use with most refrigerants but the use of

detergents containing chlorine shall be avoided as the chlorine may react with the

Loading...

Loading...