6

右后

4.

2.

3.

●

1.

⑴

⑵

1.

2.

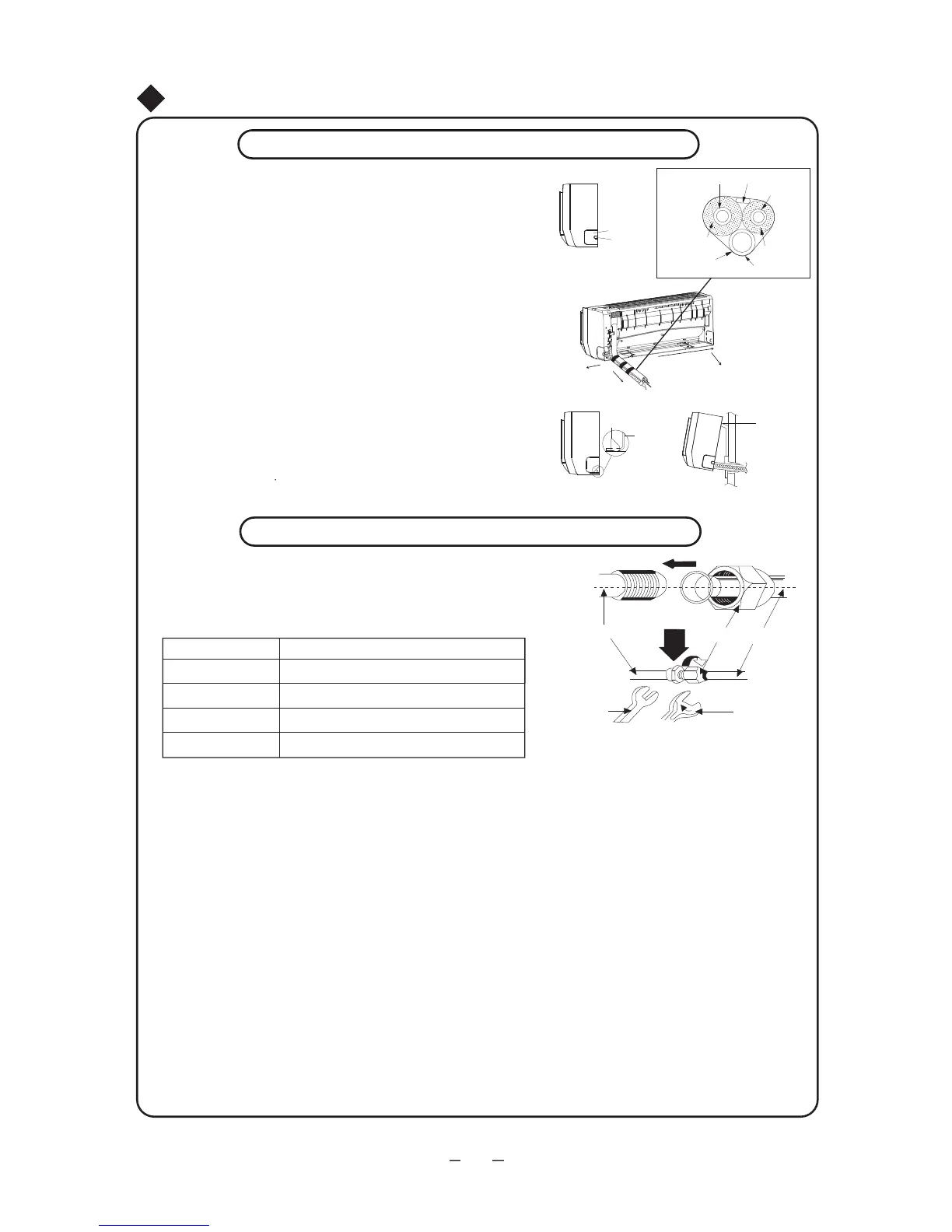

Installation of Indoor Unit

The piping can be output from right, right rear, left

or left rear.

When routing the piping and wiring from the left

or right side of indoor unit, cut off the tailings

from the chassis when necessary(As shown in Fig.7)

Cut off tailing 1 when routing the wiring only;

Cut off tailing 1 and tailing 2 when routing

both the wiring and piping.

Take out the piping from body case; wrap the piping,

power cords, drain hose with the tape and then make

them pass through the piping hole. (As shown in Fig.8)

Hang the mounting slots of the indoor unit on the

upper hooks of the mounting plate and check if it is

firm enough. (As shown in Fig.9)

The installation site should be 98 3/7 inch or more

above the floor

.

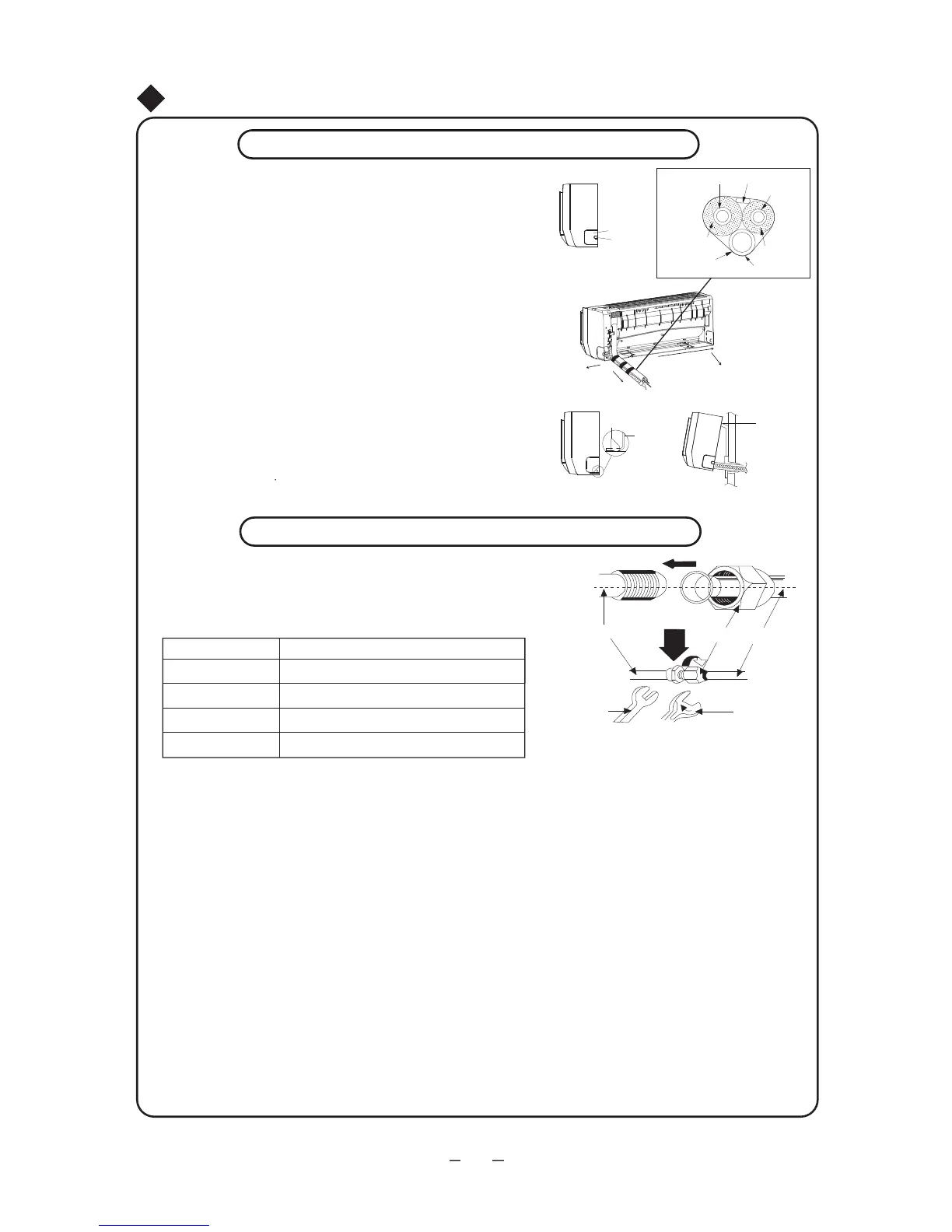

Installation of Connection Pipe

Align the center of the pipe flare with the related valve.

Screw in the flare nut by hand and then tighten the

nut with spanner and torque wrench by referring to the

following:

NOTE: Connect the connection pipe to indoor unit at first and then to outdoor unit. Handle pi-

ping bending with care. Do not damage the connection

pipe. Ensure that the joint nut

is tightened firmly, otherwise, it may cause leakage.

Spanner

Torque

wrench

Piping

Taper nut

Indoor unit piping

Fig.9

Mounting

plate

Fixing hook

Mounting

plate

Right

Right rear

Fig.8

Left rear

Left

Fig.7

Tailing 1

Tailing 2

Finally wrap it

with tape

Gas side piping

insulation

Water drainage pipe

Liquid side

Piping insulation

Gas side piping

External connection

electric wire

Liquid side piping

(N·m)

Ф6.35(1/4”)

Ф9.52(3/8”)

Ф12.7(1/2”)

Ф15.88(5/8”)

34~42N·m(340-420kgf.cm)

14~18N·m(140-180kgf.cm)

49~61N·m(490-610kgf.cm)

68~82N·m(680-820kgf.cm)

Tube diameter

Tightening torque,approximate

Installation of Indoor Unit

Loading...

Loading...